Uh, oh… not again.

Posted: 23 Jan 2025 4:39 pm

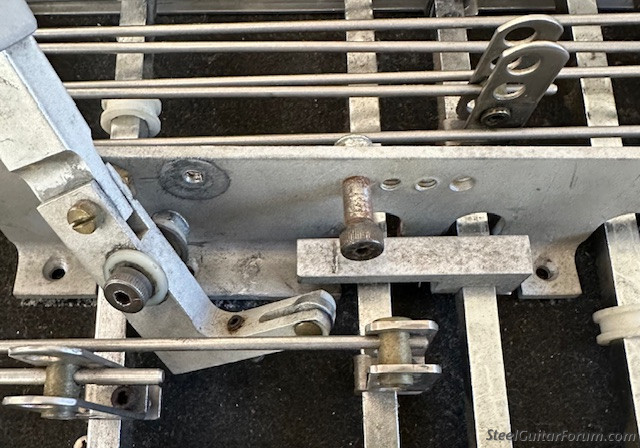

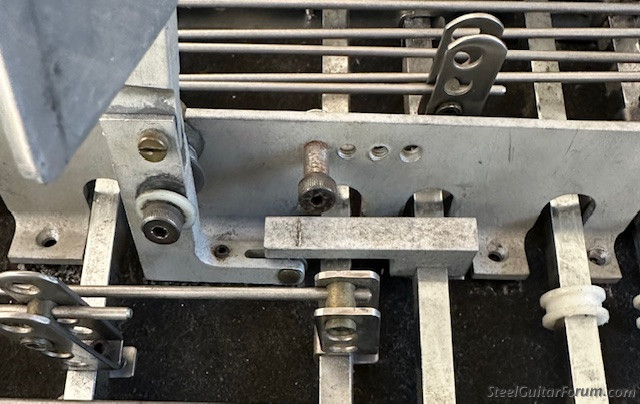

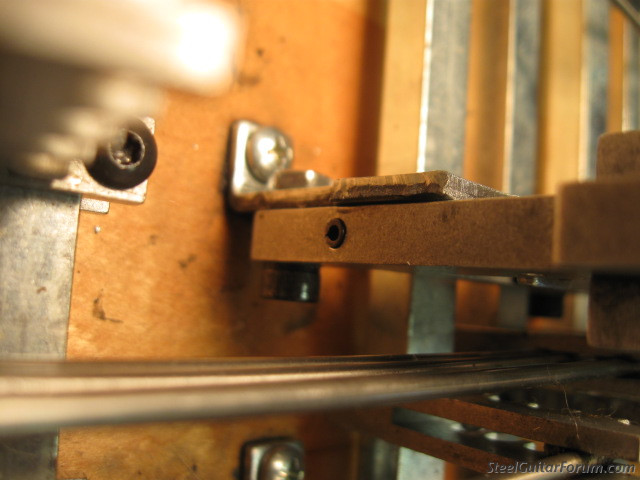

This is the second knee lever part that dramatically failed on my 2002 Carter.

I know, I know: don’t press so hard!

Last time it happened on the bandstand, ugh. Fortunately it was a seldom used RKR working both necks and did the E9 second string double lower as well as the C6 neck 3rd string lower, so pressing against 4 return springs at full travel.

This time it was at home (whew!) and the more often used LKR lowering both E’s on E9. Sure has had many thousands of cycles over 23 years. This time I had a replacement part ready for quick swap out.

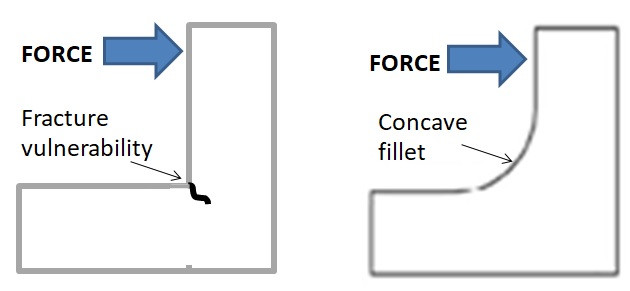

Still, I think this is a design flaw. The sharp inside corner on that lever crank is just asking for a stress crack. The reversing mechanism has two cranks sliding against each other with a sliding leverage design I just don’t think is smart. I keep it well lubricated with lithium grease. Notable that both failures were on left moving lever thru this type of linkage.

Anybody else have this problem on a Carter?

I know, I know: don’t press so hard!

Last time it happened on the bandstand, ugh. Fortunately it was a seldom used RKR working both necks and did the E9 second string double lower as well as the C6 neck 3rd string lower, so pressing against 4 return springs at full travel.

This time it was at home (whew!) and the more often used LKR lowering both E’s on E9. Sure has had many thousands of cycles over 23 years. This time I had a replacement part ready for quick swap out.

Still, I think this is a design flaw. The sharp inside corner on that lever crank is just asking for a stress crack. The reversing mechanism has two cranks sliding against each other with a sliding leverage design I just don’t think is smart. I keep it well lubricated with lithium grease. Notable that both failures were on left moving lever thru this type of linkage.

Anybody else have this problem on a Carter?

[/img]

[/img]