Fender 800 cable repair

Moderator: Dave Mudgett

-

Paul Strojan

- Posts: 253

- Joined: 15 Aug 2019 10:19 pm

- Location: California, USA

Fender 800 cable repair

I just had a cable pull out of a pulley on my fender 800 and I was wondering if I had to solder it back in place or if it would be possible to use something like j-b weld to put it back in place?

Also the block doesn't quite feel like it is working as smoothly as it should is there a simple fix?

Also the block doesn't quite feel like it is working as smoothly as it should is there a simple fix?

-

John Haspert

- Posts: 174

- Joined: 4 Aug 2008 4:16 pm

- Location: Illinois, USA

Fender 800

Jim Palenscar is your guy. He's in Oceanside, CA. Steel Guitars of North County. He is an excellent tech and a very nice guy.

Pedal Steel Guitar is "Music from Heaven"

-

Rick McNamara

- Posts: 105

- Joined: 3 Jan 2016 10:34 am

- Location: Michigan, USA

Fender 800 Cable Repair

Howdy Paul,

JB Weld is good stuff but I don’t feel this is the place to use it? There’s not a lot of clearance between the diameter of the wire and the hole it goes into, so I’m not sure it would hold for long?

A little flux and solder and 5 minutes with a propane torch, and you’re ready to go! No different than sweating a copper fitting. A small price to pay for a quiet, smooth pull system.

If your Fender 800 still has original style cables, the balance pulley (as I refer to it), should be triangular in shape. The tabs on corners of two of the three triangle points create drag on the cable by design when the cable is not under tension. This restriction reduces the amount of flare out (slack) at the balance pulley in the cable. This helps to keep the amount of pull required for a tone change as small as possible without pulling the changer actuator off it’s open tuning stop.

The the earlier balance pulleys were round (400 and 1000 models) and allowed the cable to flare out around the balance pulley even with good tension on the cable adjuster. This increased pedal pull travel on tone changes. More of an issue on full tone changes and some knee levers that do not have enough mechanical advantage to create a full tone change.

If the sheave in the pulley is not moving freely, a little light oil(3n1 is my favorite) should free it up.

Regards,

Rick

JB Weld is good stuff but I don’t feel this is the place to use it? There’s not a lot of clearance between the diameter of the wire and the hole it goes into, so I’m not sure it would hold for long?

A little flux and solder and 5 minutes with a propane torch, and you’re ready to go! No different than sweating a copper fitting. A small price to pay for a quiet, smooth pull system.

If your Fender 800 still has original style cables, the balance pulley (as I refer to it), should be triangular in shape. The tabs on corners of two of the three triangle points create drag on the cable by design when the cable is not under tension. This restriction reduces the amount of flare out (slack) at the balance pulley in the cable. This helps to keep the amount of pull required for a tone change as small as possible without pulling the changer actuator off it’s open tuning stop.

The the earlier balance pulleys were round (400 and 1000 models) and allowed the cable to flare out around the balance pulley even with good tension on the cable adjuster. This increased pedal pull travel on tone changes. More of an issue on full tone changes and some knee levers that do not have enough mechanical advantage to create a full tone change.

If the sheave in the pulley is not moving freely, a little light oil(3n1 is my favorite) should free it up.

Regards,

Rick

-

Dave Zirbel

- Posts: 4270

- Joined: 4 Aug 1998 11:00 pm

- Location: Sebastopol, CA USA

-

Paul Strojan

- Posts: 253

- Joined: 15 Aug 2019 10:19 pm

- Location: California, USA

-

John Haspert

- Posts: 174

- Joined: 4 Aug 2008 4:16 pm

- Location: Illinois, USA

Fender cables

I did talk to Jim about these. He said the key to success with the soldering is to acid etch the part of the cable to be soldered. You’ll probably want to do this outdoors. He showed me the spot on his work bench where he did this and you could see where the acid vapors had attacked the metal surfaces nearby. When done with the soldering you’ll want to neutralize the acid left over from the etching and the flux.

Pedal Steel Guitar is "Music from Heaven"

-

Donny Hinson

- Posts: 21781

- Joined: 16 Feb 1999 1:01 am

- Location: Glen Burnie, Md. U.S.A.

No, no glue or epoxy will hold that well on small surface-area joints (compared to soldering).

You can silver-solder or braze it with the proper flux and a propane torch (best).

or you can use silver bearing solder, flux, and a propane torch (next best).

or you can use 70/30 acid-flux solder (just "okay").

The least acceptable is to use standard electrical solder with a paste or liquid flux...because electrical solder is pretty soft, and not that great for mechanical joints.

You can silver-solder or braze it with the proper flux and a propane torch (best).

or you can use silver bearing solder, flux, and a propane torch (next best).

or you can use 70/30 acid-flux solder (just "okay").

The least acceptable is to use standard electrical solder with a paste or liquid flux...because electrical solder is pretty soft, and not that great for mechanical joints.

-

Abe Levy

- Posts: 1018

- Joined: 26 Sep 2008 9:29 pm

- Location: California, USA

-

Michael Sawyer

- Posts: 264

- Joined: 15 Jun 2019 8:32 am

- Location: North Carolina, USA

-

Michael Sawyer

- Posts: 264

- Joined: 15 Jun 2019 8:32 am

- Location: North Carolina, USA

-

Jim Sliff

- Posts: 7060

- Joined: 22 Jun 2005 12:01 am

- Location: Lawndale California, USA

Old thread, but just in case anyone finds it-

Electrical solder (ANY containing lead) will fail. It's both soft and has poor adhesive qualities. It's only meant to secure an already good mechanical connection. It's not a glue even in electronics.

And JB Weld (and similar epoxies)) also have very poor long-term performance.

Also - resoldering old cables is a bad idea. Once one has failed the old flux and solder is permanently gunked on the strands, and no solvent or etching will get it all out. It has also degraded and ruins the joint. New 1/16"galvanized wire rope (NOT stainless steel - needs even more expensive brazing materials) , muriatic acid to etch the end, a propane or butane torch, acid flux and silver bearing solder are what I've used for years on about 25-30 guitars with no failures.

You can download a soldering guide in the files section of the Facebook Fender Pedal Steel section - that Facebook group s where you'll find most of the info posted by experienced techs.

Electrical solder (ANY containing lead) will fail. It's both soft and has poor adhesive qualities. It's only meant to secure an already good mechanical connection. It's not a glue even in electronics.

And JB Weld (and similar epoxies)) also have very poor long-term performance.

Also - resoldering old cables is a bad idea. Once one has failed the old flux and solder is permanently gunked on the strands, and no solvent or etching will get it all out. It has also degraded and ruins the joint. New 1/16"galvanized wire rope (NOT stainless steel - needs even more expensive brazing materials) , muriatic acid to etch the end, a propane or butane torch, acid flux and silver bearing solder are what I've used for years on about 25-30 guitars with no failures.

You can download a soldering guide in the files section of the Facebook Fender Pedal Steel section - that Facebook group s where you'll find most of the info posted by experienced techs.

No chops, but great tone

1930's/40's Rickenbacher/Rickenbacker 6&8 string lap steels

1921 Weissenborn Style 2; Hilo&Schireson hollownecks

Appalachian, Regal & Dobro squarenecks

1959 Fender 400 9+2 B6;1960's Fender 800 3+3+2; 1948 Fender Dual-8 Professional

1930's/40's Rickenbacher/Rickenbacker 6&8 string lap steels

1921 Weissenborn Style 2; Hilo&Schireson hollownecks

Appalachian, Regal & Dobro squarenecks

1959 Fender 400 9+2 B6;1960's Fender 800 3+3+2; 1948 Fender Dual-8 Professional

-

Chris Lucker

- Posts: 3165

- Joined: 11 Aug 1999 12:01 am

- Location: Los Angeles, California USA

I would recommend stainless cable over galvanized, for the simple fact that your solder bonds directly to the cable not a galvanized coating interface. Because of the nature of stranded cable, it is impossible to remove all of the galvanized coating while soldering.

To properly solder stainless, use a torch, use flux made for soldering stainless and use silver solder. Or pay someone to do the job properly.

I have worked with stainless steel cable solder joints on countless Bigsbys, Wrights, Fenders, Campbells and sailboats. Sure, galvanized cable solder joints may not fail on something with low stress like a pedal steel guitar, but you would not find it on a sailboat.

Here is a tip for sourcing pulleys. While I have a lathe so I machine my own pulleys, you can also use the appropriate sized metal pulleys from old Erector Sets.

To properly solder stainless, use a torch, use flux made for soldering stainless and use silver solder. Or pay someone to do the job properly.

I have worked with stainless steel cable solder joints on countless Bigsbys, Wrights, Fenders, Campbells and sailboats. Sure, galvanized cable solder joints may not fail on something with low stress like a pedal steel guitar, but you would not find it on a sailboat.

Here is a tip for sourcing pulleys. While I have a lathe so I machine my own pulleys, you can also use the appropriate sized metal pulleys from old Erector Sets.

Chris Lucker

Red Bellies, Bigsbys and a lot of other guitars.

Red Bellies, Bigsbys and a lot of other guitars.

-

Jim Sliff

- Posts: 7060

- Joined: 22 Jun 2005 12:01 am

- Location: Lawndale California, USA

The muriatic acid etch removes the galvanized coating. That is the point of the etch.

The amount of hat required for stainless cable cn easily burn through the thin copper tubing used for changer loops. That and the difficulty getting good flow without extreme heat is why I suggest sticking with galvanized cable and original type aluminum or steel pulleys, turnbuckes and changer wire.

Never had a failure using the methods in the soldering guide on the Facebook "files" section. I use to sail as well and what's needed for sailing is overkill for Fender pedal steels. The average player/owner will have a much easier time - and spend less money - avoiding stainless steel.

The amount of hat required for stainless cable cn easily burn through the thin copper tubing used for changer loops. That and the difficulty getting good flow without extreme heat is why I suggest sticking with galvanized cable and original type aluminum or steel pulleys, turnbuckes and changer wire.

Never had a failure using the methods in the soldering guide on the Facebook "files" section. I use to sail as well and what's needed for sailing is overkill for Fender pedal steels. The average player/owner will have a much easier time - and spend less money - avoiding stainless steel.

No chops, but great tone

1930's/40's Rickenbacher/Rickenbacker 6&8 string lap steels

1921 Weissenborn Style 2; Hilo&Schireson hollownecks

Appalachian, Regal & Dobro squarenecks

1959 Fender 400 9+2 B6;1960's Fender 800 3+3+2; 1948 Fender Dual-8 Professional

1930's/40's Rickenbacher/Rickenbacker 6&8 string lap steels

1921 Weissenborn Style 2; Hilo&Schireson hollownecks

Appalachian, Regal & Dobro squarenecks

1959 Fender 400 9+2 B6;1960's Fender 800 3+3+2; 1948 Fender Dual-8 Professional

-

Chris Lucker

- Posts: 3165

- Joined: 11 Aug 1999 12:01 am

- Location: Los Angeles, California USA

I don’t understand your concern about burning through the copper tube. If you solder correctly, you apply the appropriate heat for each material. You don’t heat the copper, for example, to the heat required for the stainless. There are pickups where you solder 44ga copper wire to stainless screws. Correct soldering technique does not burn through the fine coil wire.

Chris Lucker

Red Bellies, Bigsbys and a lot of other guitars.

Red Bellies, Bigsbys and a lot of other guitars.

-

Stu Schulman

- Posts: 6523

- Joined: 15 Oct 1998 12:01 am

- Location: Ulster Park New Yawk (deceased)

This thread fascinates me,I have never played a cable guitar,and had no idea how much other stuff has to be dealt with...I'm assuming that Sneaky Pete was great at this stuff?

Steeltronics Z-pickup,Desert Rose S-10 4+5,Desert Rose Keyless S-10 3+5... Mullen G2 S-10 3+5,Telonics 206 pickups,Telonics volume pedal.,Blanton SD -10,Emmons GS_10...Zirctone bar,Bill Groner Bar...any amp that isn't broken.Steel Seat.Com seats...Licking paint chips off of Chinese Toys since 1952.

-

K Maul

- Posts: 2205

- Joined: 14 Feb 2000 1:01 am

- Location: Hadley, NY/Hobe Sound, FL

Broken cables really are rare and occur because of a cable being way way over tightened, a poor previous repair or from stomping on the pedals too hard when something was out of whack. Jim’s suggestion for fixing it is really the best way to keep these problems from re-occurring. I don’t know how much work Pete did on his own steel. Jim might know because he had quite a bit of personal contact with him in the later years.

KEVIN MAUL: Airline, Beard, Clinesmith, Danelectro, Evans, Fender, Gibson, Hilton, Ibanez, Justice, K+K, Live Strings, MOYO, National, Oahu, Peterson, Quilter, Rickenbacher, Sho~Bud, Supro, TC, Ultimate, VHT, Williams, Xotic, Yamaha, ZKing.

-

Chris Templeton

- Posts: 3431

- Joined: 25 Sep 2012 4:20 pm

- Location: The Green Mountain State

I had three Fender 400's in the early nineties. One became a parts guitar for the other two, but I never dealt with a broken cable.

I'm with Stu on this.

All the techniques, experience and suggestions about broken cables are fascinating to me, too.

The forum is such a great place for all kinds of steel knowledge.

I'm with Stu on this.

All the techniques, experience and suggestions about broken cables are fascinating to me, too.

The forum is such a great place for all kinds of steel knowledge.

Excel 3/4 Pedal With An 8 String Hawaiian Neck, Sierra Tapper (10 string with a raised fretboard to fret with fingers), Single neck Fessenden 3/5

"The Tapper" : https://christophertempleton.bandcamp.c ... the-tapper

Soundcloud Playlist: https://soundcloud.com/bluespruce8:

"The Tapper" : https://christophertempleton.bandcamp.c ... the-tapper

Soundcloud Playlist: https://soundcloud.com/bluespruce8:

-

Donny Hinson

- Posts: 21781

- Joined: 16 Feb 1999 1:01 am

- Location: Glen Burnie, Md. U.S.A.

The cables didn't break, rather, the solder joints pulled apart. Usually, from the pulleys. Fixing them was something most players just knew how to do back then. You cleaned the cable with alcohol and a wire brush, ran a drill into the pulley or brass ferrule to clean it out, and soldered them with an iron or torch. (Personally, I used a 250 watt gun.) And for all that say soldering was no good at all, that's the way they were done at the factory. Of course, silver solder would have been best, but it was expensive, and Leo Fender was the original cheapskate.

Fixing mechanical stuff was a very common talent back in the middle of the last century. Sadly, the average person these days seems to have little in the way of mechanical skills.

Fixing mechanical stuff was a very common talent back in the middle of the last century. Sadly, the average person these days seems to have little in the way of mechanical skills.

-

Chris Templeton

- Posts: 3431

- Joined: 25 Sep 2012 4:20 pm

- Location: The Green Mountain State

Yes, solder joints. Excuse.

Excel 3/4 Pedal With An 8 String Hawaiian Neck, Sierra Tapper (10 string with a raised fretboard to fret with fingers), Single neck Fessenden 3/5

"The Tapper" : https://christophertempleton.bandcamp.c ... the-tapper

Soundcloud Playlist: https://soundcloud.com/bluespruce8:

"The Tapper" : https://christophertempleton.bandcamp.c ... the-tapper

Soundcloud Playlist: https://soundcloud.com/bluespruce8:

-

Dennis Montgomery

- Posts: 871

- Joined: 15 Feb 2016 9:28 pm

- Location: Western Washington

I had one on my Fender 400 break a couple years ago...well not so much break as the cable popped out from the pulley. Went to Home Depot and got a silver solder/small propane tank kit for about $50. I've had lots of experience with solder guns but never a propane tank so it took me a couple tries, but got it done and it hasn't come loose since

Hear my latest album, "Celestial" featuring a combination of Mullen SD12 and Synthesizers:

https://www.youtube.com/watch?v=mhh6b_x ... Ww493qAouK

Hear my album, "Armistice" featuring Fender 400 on every song:

https://www.youtube.com/playlist?list=P ... 7lPEtsplyW

Hear my Pedal Steel Only playlist featuring Mullen G2 SD12 on covers like Candyman, Wild Horses, Across the Universe & more...

https://www.youtube.com/playlist?list=P ... NrvnJObliA

https://www.youtube.com/watch?v=mhh6b_x ... Ww493qAouK

Hear my album, "Armistice" featuring Fender 400 on every song:

https://www.youtube.com/playlist?list=P ... 7lPEtsplyW

Hear my Pedal Steel Only playlist featuring Mullen G2 SD12 on covers like Candyman, Wild Horses, Across the Universe & more...

https://www.youtube.com/playlist?list=P ... NrvnJObliA

-

Jim Sliff

- Posts: 7060

- Joined: 22 Jun 2005 12:01 am

- Location: Lawndale California, USA

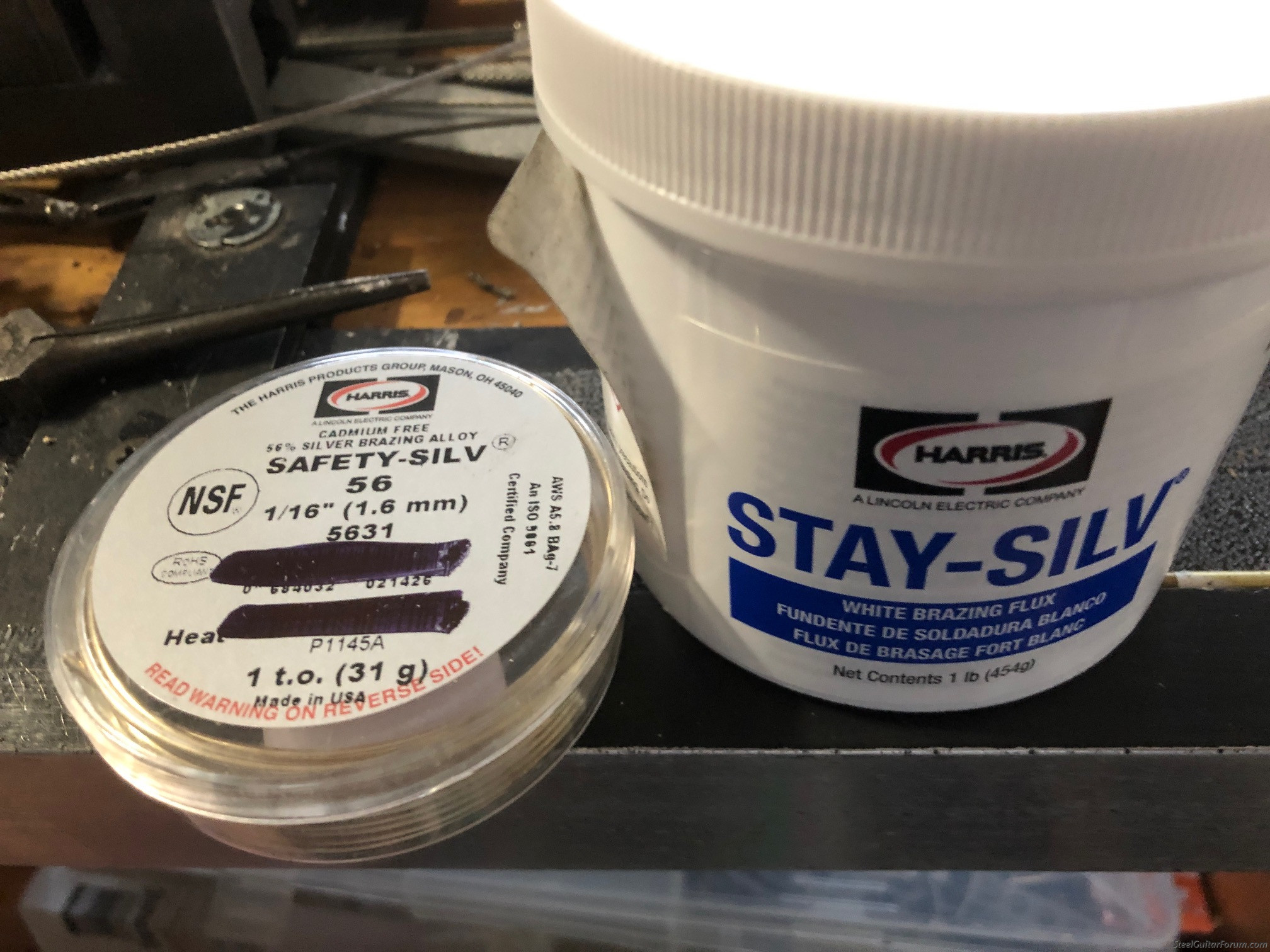

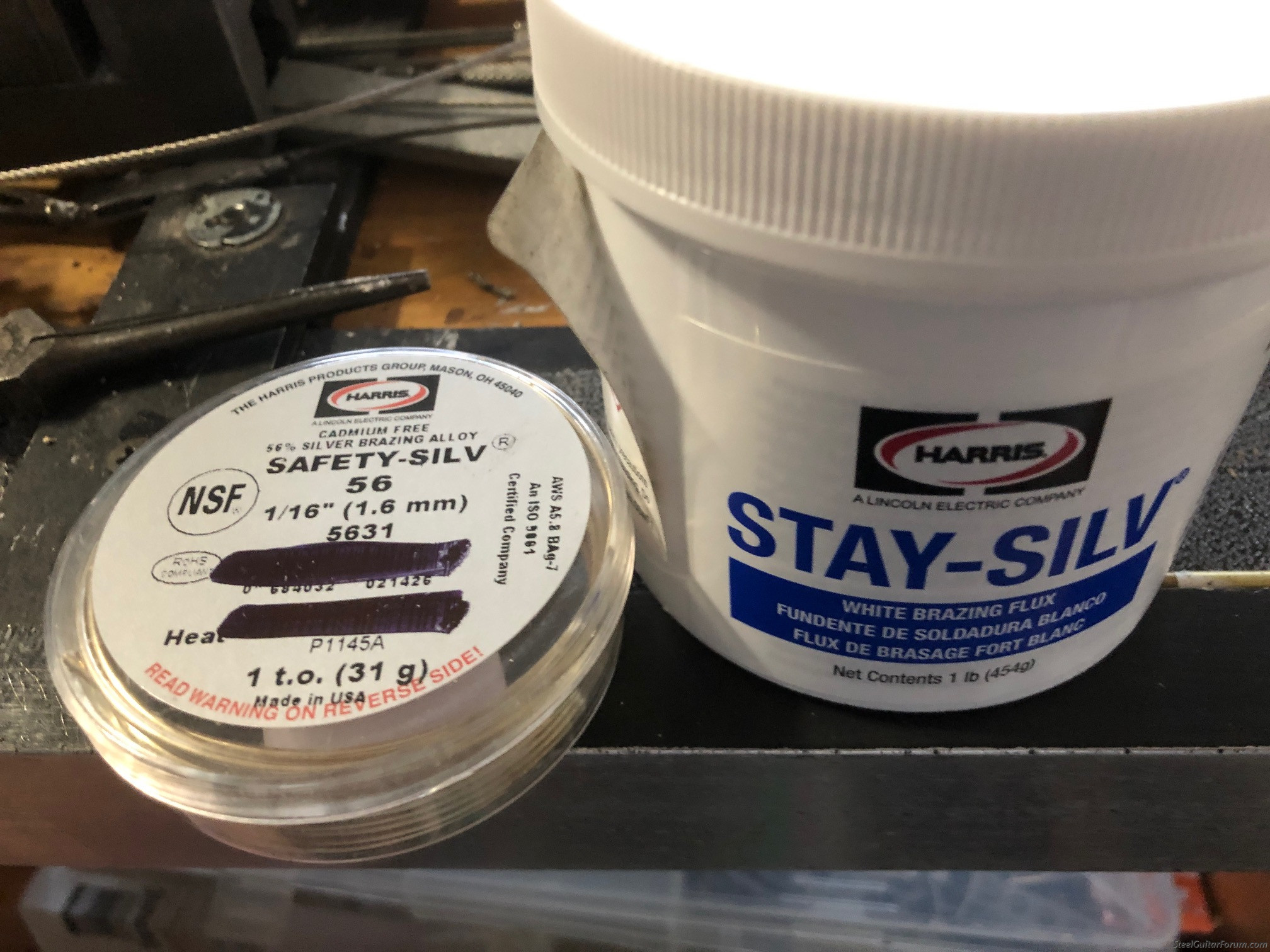

Chris - re stainless and copper tubing, by the point where there's enough heat to get Harris Safety Silv 56 to melt/wick into the cable it cooks through the tubing. Same issue with the changer wire side - melting the solder into the tube burns up the tube. And $40 for a specific silver bearing solder (I already have 3 other types of silver solder) isn't a minor expense for me.

Especially when it turns out to be even more problematic. It's nearly as stiff as a coat hanger, and the pulley or turnbuckle end has to be literally red-hot to melt the solder - sort of.

But it never flows, no matter how I use the torch. It just clumps around the top of the hole, while the fluxed cable chars & frays so it can't be inserted. Pre-inserting the cable doesn't help - with both parts fluxed the solder simply won't wick into the cable/hole. Here are some pics of some of the parts I'm using - and the aftermath . (I forgot to take one of a fried piece of tubing) it just looks like dull metal "dirt clods" sitting on top of the hot - or it falls off the side.

. (I forgot to take one of a fried piece of tubing) it just looks like dull metal "dirt clods" sitting on top of the hot - or it falls off the side.

It's laughably embarrassing, since I wrote the cable soldering guide that's on the Facebook Fender Pedal Steel section - but that was based on stock parts and galvanized cable, which I've never had an issue with. I can assemble a turnbuckle/pulley.dual-loop assembly in about 15 minutes using a butane or propane torch.

Dave Evans, who makes most of my Pull String B-benders and is a professional machinist did me a huge favor making a few pulleys and turnbuckles for my SD800 project guitar - all out of stainless steel. The holes for cable insertion are all threaded for some mechanical "grab" - but melting the solder and not charring the cable are the issues at that end; burnt-out tubing, wire loops with no solder at all and charred/frayed cable the problem at the other.

It's not a conventional setup - it currently has A/B/C pedals plus 9 &10 - I'm adding 3 knee levers and one additional pedal, and I need to experiment/test various lengths to position the levers, have the changer loops line up straight and avoid pulleys interfering with other parts - and each other.

So it's a trial-and-error project & I can't have anyone make them "to order". It has to be done here. I'd prefer to use the stainless pulleys with galvanized cable so I can use the few old turnbuckles I have left and not have to deal with the stainless ones.

Ideas are welcome - YouTube has been no help, nor have any websites. The cable is an unusual component so there are no relevant examples.

Thanks -

Especially when it turns out to be even more problematic. It's nearly as stiff as a coat hanger, and the pulley or turnbuckle end has to be literally red-hot to melt the solder - sort of.

But it never flows, no matter how I use the torch. It just clumps around the top of the hole, while the fluxed cable chars & frays so it can't be inserted. Pre-inserting the cable doesn't help - with both parts fluxed the solder simply won't wick into the cable/hole. Here are some pics of some of the parts I'm using - and the aftermath

It's laughably embarrassing, since I wrote the cable soldering guide that's on the Facebook Fender Pedal Steel section - but that was based on stock parts and galvanized cable, which I've never had an issue with. I can assemble a turnbuckle/pulley.dual-loop assembly in about 15 minutes using a butane or propane torch.

Dave Evans, who makes most of my Pull String B-benders and is a professional machinist did me a huge favor making a few pulleys and turnbuckles for my SD800 project guitar - all out of stainless steel. The holes for cable insertion are all threaded for some mechanical "grab" - but melting the solder and not charring the cable are the issues at that end; burnt-out tubing, wire loops with no solder at all and charred/frayed cable the problem at the other.

It's not a conventional setup - it currently has A/B/C pedals plus 9 &10 - I'm adding 3 knee levers and one additional pedal, and I need to experiment/test various lengths to position the levers, have the changer loops line up straight and avoid pulleys interfering with other parts - and each other.

So it's a trial-and-error project & I can't have anyone make them "to order". It has to be done here. I'd prefer to use the stainless pulleys with galvanized cable so I can use the few old turnbuckles I have left and not have to deal with the stainless ones.

Ideas are welcome - YouTube has been no help, nor have any websites. The cable is an unusual component so there are no relevant examples.

Thanks -

No chops, but great tone

1930's/40's Rickenbacher/Rickenbacker 6&8 string lap steels

1921 Weissenborn Style 2; Hilo&Schireson hollownecks

Appalachian, Regal & Dobro squarenecks

1959 Fender 400 9+2 B6;1960's Fender 800 3+3+2; 1948 Fender Dual-8 Professional

1930's/40's Rickenbacher/Rickenbacker 6&8 string lap steels

1921 Weissenborn Style 2; Hilo&Schireson hollownecks

Appalachian, Regal & Dobro squarenecks

1959 Fender 400 9+2 B6;1960's Fender 800 3+3+2; 1948 Fender Dual-8 Professional

-

Jon Zimmerman

- Posts: 1087

- Joined: 25 May 2005 12:01 am

- Location: California, USA

Looks to me like there is no “simple fix” Paul. Most folks today have no vice at home to secure ‘hot stuff’ with. If you have an adept friend with skills and time to help you, after looking over the Facebook entry mentioned or others herein, try that approach. Saves burned fingers, and you’ll need em to play your Fender.

-

Chris Lucker

- Posts: 3165

- Joined: 11 Aug 1999 12:01 am

- Location: Los Angeles, California USA

-

Chris Lucker

- Posts: 3165

- Joined: 11 Aug 1999 12:01 am

- Location: Los Angeles, California USA

Jim, Did you see the NASDAQ dipped 2.8% today?

That is because you wrote the rules on how to solder on some vanity Internet site.

Now, industry knows they have been manufacturing wrong.

Wrong all along.

Because it is not your way, which you tell us is the only way.

Gosh, have mercy on the stock market. You are so wise and that makes you so powerful.

That is because you wrote the rules on how to solder on some vanity Internet site.

Now, industry knows they have been manufacturing wrong.

Wrong all along.

Because it is not your way, which you tell us is the only way.

Gosh, have mercy on the stock market. You are so wise and that makes you so powerful.

Chris Lucker

Red Bellies, Bigsbys and a lot of other guitars.

Red Bellies, Bigsbys and a lot of other guitars.

-

Andrew Goulet

- Posts: 533

- Joined: 6 Oct 2010 7:05 pm

Well…moving on…

I’m a DIY hack, a self-taught tinkerer, and when I had a Fender I was never comfortable trying to solder a cable and pulley assembly. So I made them out of galvanized cable, cable clamps, and the smallest pulleys with a 30 lb. load that I could find. I looped the cable around the changer finger and secured it with another clamp.

Now, I know this may not be the most mechanically efficient system, but in 10 years I had only two cables break, and that was because of the poor job I had done on the cable loop. After adjusting turnbuckles (also from the hardware store) properly, my pedals were whip-fast while also being soft. There was almost no squish in the system at all.

Just something to consider. I play a fairly simple copedent, so it may not work if you’re creating an extended chord juggernaut.

I’m a DIY hack, a self-taught tinkerer, and when I had a Fender I was never comfortable trying to solder a cable and pulley assembly. So I made them out of galvanized cable, cable clamps, and the smallest pulleys with a 30 lb. load that I could find. I looped the cable around the changer finger and secured it with another clamp.

Now, I know this may not be the most mechanically efficient system, but in 10 years I had only two cables break, and that was because of the poor job I had done on the cable loop. After adjusting turnbuckles (also from the hardware store) properly, my pedals were whip-fast while also being soft. There was almost no squish in the system at all.

Just something to consider. I play a fairly simple copedent, so it may not work if you’re creating an extended chord juggernaut.

Marlen S12 pedal steel

12 string Bill Hatcher lap steel

ZT Club and Lunchbox

12 string Bill Hatcher lap steel

ZT Club and Lunchbox