I announce my new project in January this year when I started working on it. I thought its time for an update.

Progress is slow but surely going forward. There however were some challenges to overcome from my originally Wishlist.

My Wishlist.

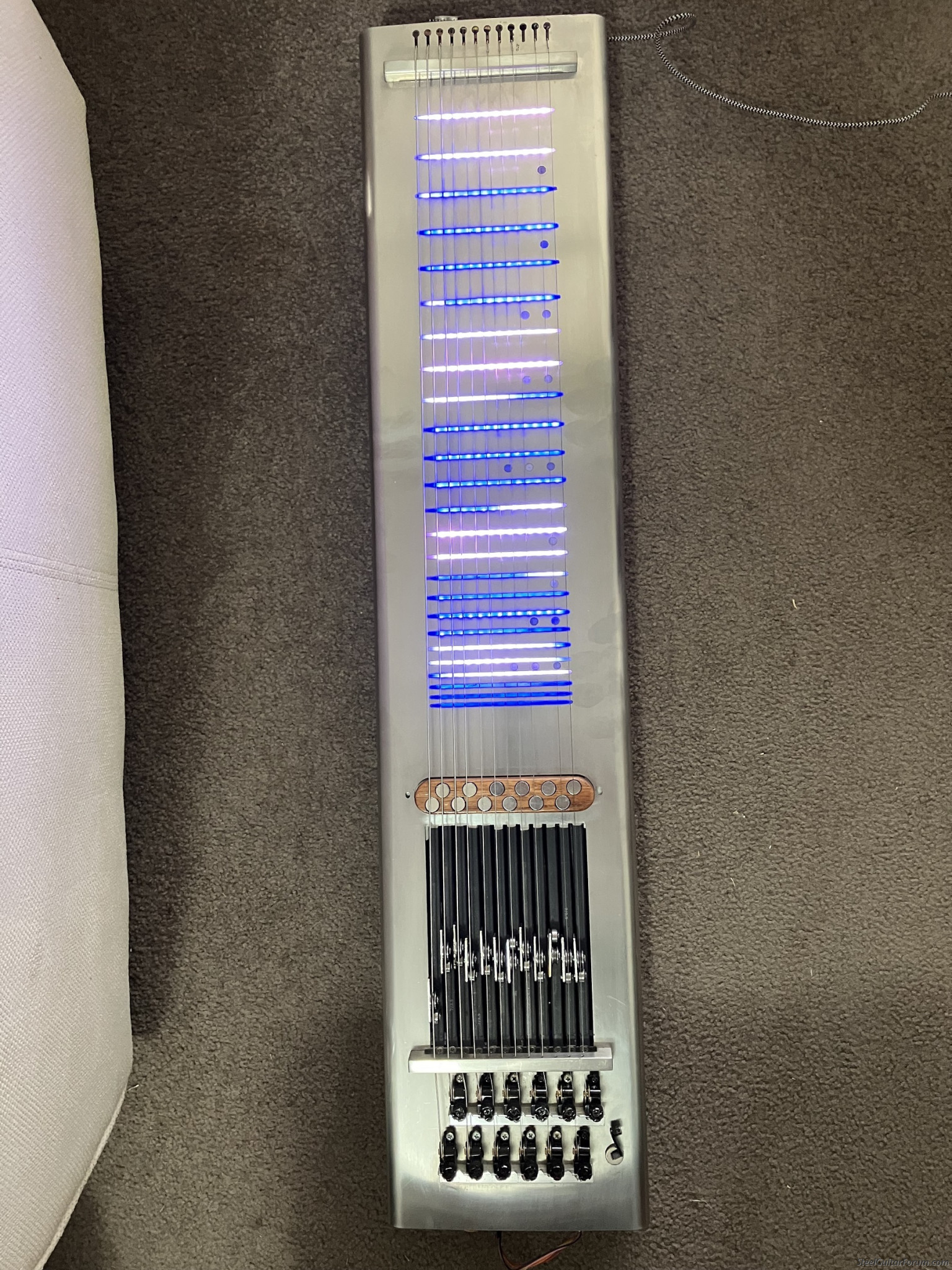

1) Guitar will have a stainless steel body which is laser cut. (Done)

2) The guitar will not have tuning pegs at the nut side but instead it will be tuned at the bridge. Done.

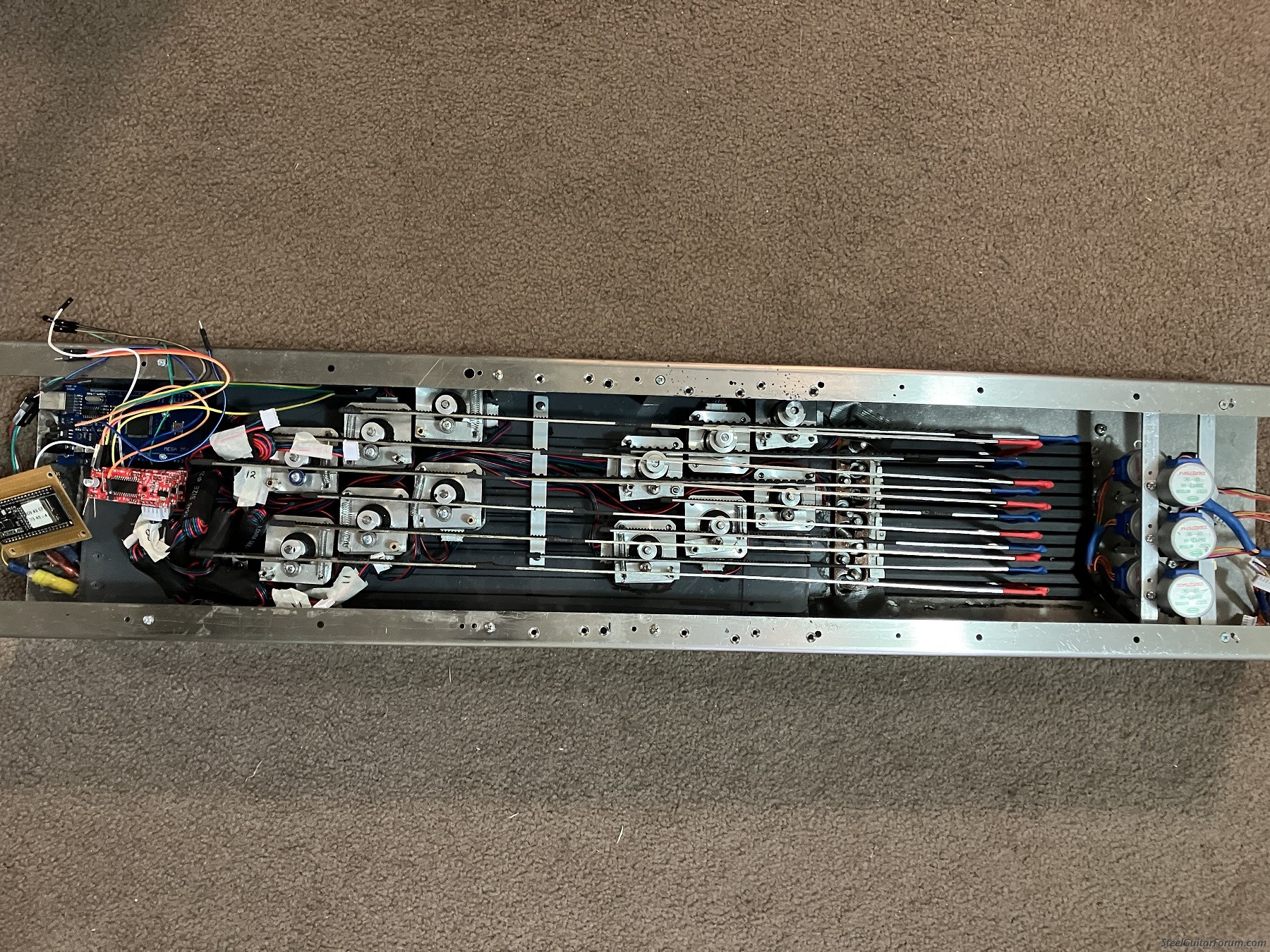

Strings will be adjusted with three methods.

a) Manually by finger. Done.

b) Manually using a small handle to wind, it's faster.

c) Auto tuning where the guitar will tune itself in auto tune mode. This will be a completely new concept. I already done some tests and it does work. Code 50% done.

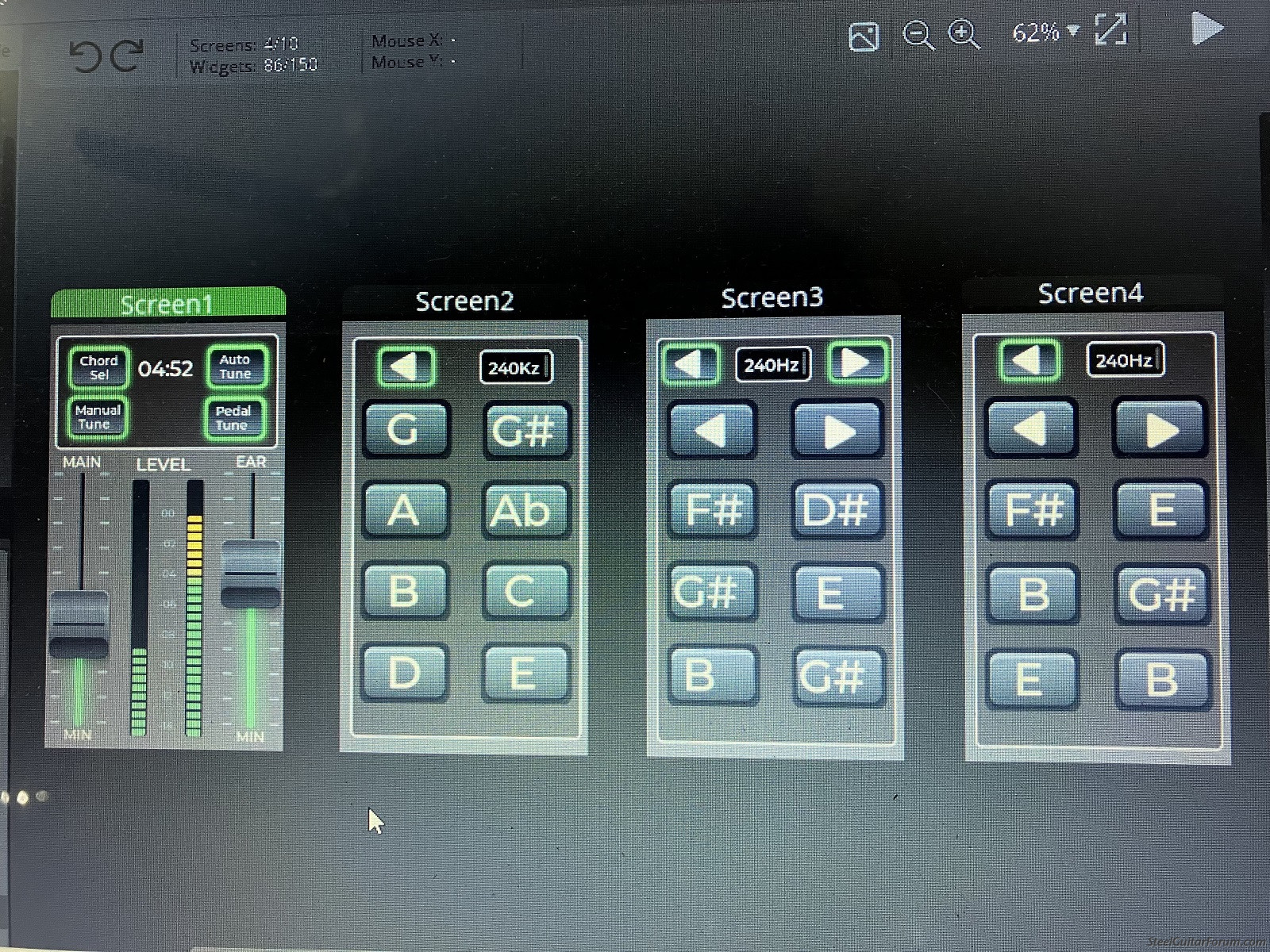

3) The Guitar will have a touchscreen display, which will house all controls for tuning, chord select, changing from E9 to C6 and more. Touch screens done. Screenshot Attached.

4) This design will use stepper motors. installation completed.

5) With this design the strings will not be stretching to change the pitch. More later on.

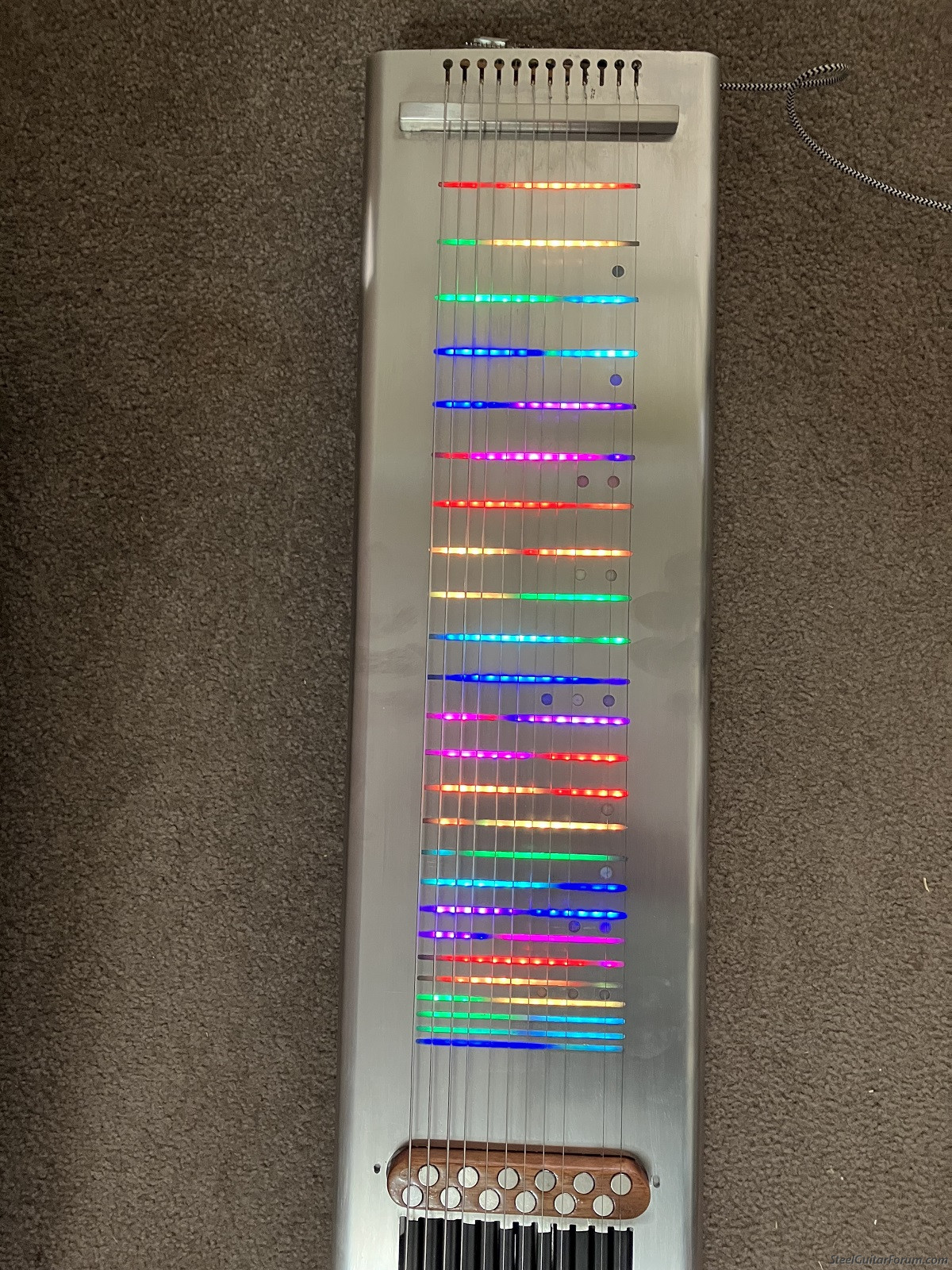

6) The fret on the fret board on this build will be lit up in any colour, selected in the parameter list. Done see pictures.

7) The fret on the fret board will also be used as follow. When you play for example in "G" when you select "G" in the touch screen the corresponding frets will change to a different color. That will be useful when playing in the dark, or when in training or just because it looks nice. Done

8)Pedals A, B, C, D, and E will use "Hull sensors". My first build used potentiometers. Fone.

9) The communication from the pedals to the main panel will be wireless, as it is on the first build. Done

10) The guitar will be able to convert to C6 from the display. Code in progress.

11) The guitar will have a wireless headphones. Not done yet

12) The speaker outlet will be wireless as well. Not done yet

13) The head and tail will be rounded off with a dark wood finish, where the touch screen will be fitted at the top of the head stock.

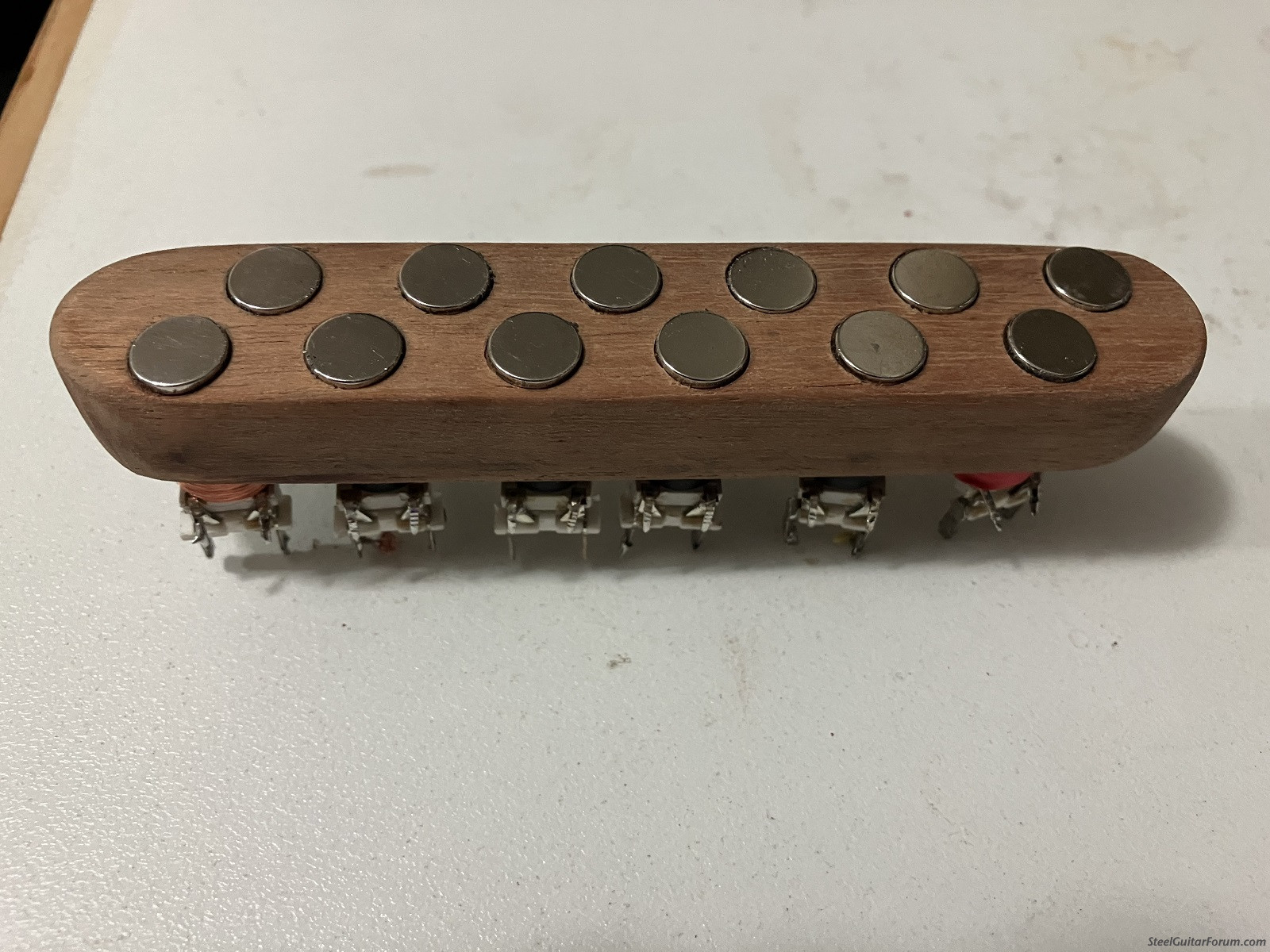

The pick-up already done with wood. It came out quite nice.

13) To achieve the auto tuning I had to create a multi wind pick-up. One coil per string. Done.

Most of the code was tested before, but all need to be compiled into a functional setup and tested. Meaning there is still lots of hours to be spend before completion.

The code up to now did give me some major issues, but I'm getting there slowly but surely.

On the hardware side a couple of you had concerns about when I move the string cage that the fret bars will be offset. I originally did not realize it, but it however will be the case. So, the plan is when all is running, I will take measurements and electronically via the software compensate for the offset. I'm confident that I can correct it via the code.