Making a Horseshoe Magnet

Moderator: Brad Bechtel

-

Michael Kiese

- Posts: 490

- Joined: 17 Jul 2023 12:27 pm

- Location: Richmond, Virginia (Hometown: Pearl City, HI)

- State/Province: West Virginia

- Country: United States

Making a Horseshoe Magnet

Hello one and all,

To my knowledge, Todd Clinesmith and Jason Lollar are the only people manufacturing modern horseshoe pickups.

My very first steel, I purchased in April 2018 from a sweet man name Jan Van der Donck from the Netherlands. It was an 8 string frypan, and he made the entire thing.

I honestly think he did a great job. I even found a couple YouTube videos of him on YouTube showing him winding his own horseshoe pickups.

It took me years to get around to learning how to play it, and now that I'm fairly proficient, I finally realize how good of an instrument it is.

I only wish Jan were still alive so that I could shower him with praise!

Anyhoo, I'm curious as to how I could fabricate my own horseshoe magnet.

To me, horseshoe magnets appear that they are an old school straight bar magnet that's been bent in half with a press brake.

Does anybody happen to know where Rickenbacher got their magnet material from, and what composition the metal is?

I've studied and researched that Horseshoe magnets are a very primitive type of early magnet that is a Cobalt infused Steel, but I've never had that verified.

All these things, I could have asked Jan himself, and I'm sure he would've been happy to tell me.

Anybody out there that know the answer, or can point me in the right direction?

Just to satisfy a fun intellectual curiosity, I was planning on buying a couple different types of magnets on Amazon, and taking them to a machine shop to bend them with press brake.

I have a funny feeling that could actually work. Might be a fun project.

Thanks in advance!

To my knowledge, Todd Clinesmith and Jason Lollar are the only people manufacturing modern horseshoe pickups.

My very first steel, I purchased in April 2018 from a sweet man name Jan Van der Donck from the Netherlands. It was an 8 string frypan, and he made the entire thing.

I honestly think he did a great job. I even found a couple YouTube videos of him on YouTube showing him winding his own horseshoe pickups.

It took me years to get around to learning how to play it, and now that I'm fairly proficient, I finally realize how good of an instrument it is.

I only wish Jan were still alive so that I could shower him with praise!

Anyhoo, I'm curious as to how I could fabricate my own horseshoe magnet.

To me, horseshoe magnets appear that they are an old school straight bar magnet that's been bent in half with a press brake.

Does anybody happen to know where Rickenbacher got their magnet material from, and what composition the metal is?

I've studied and researched that Horseshoe magnets are a very primitive type of early magnet that is a Cobalt infused Steel, but I've never had that verified.

All these things, I could have asked Jan himself, and I'm sure he would've been happy to tell me.

Anybody out there that know the answer, or can point me in the right direction?

Just to satisfy a fun intellectual curiosity, I was planning on buying a couple different types of magnets on Amazon, and taking them to a machine shop to bend them with press brake.

I have a funny feeling that could actually work. Might be a fun project.

Thanks in advance!

Aloha,

Mike K

1935 A22 Rickenbacher Frypan (C6), 1937 7string Prewar Rickenbacher Bakelite (C Diatonic), 1937 7string Epiphone Electar (Jerry Byrd's E9), 1937 Epiphone Electar (C#m9), 1940's Post War Rickenbacher Bakelite (Feet's D), 1950 Supro (Open F), 1950's Rickenbacher ACE (C6), 1950's Rickenbacher A25 Frypan (A6), 1957 National New Yorker (Jerry's E13), 1955 Q8 Fender Stringmaster (A6, C6, Noel's E13, C Diatonic), 1961 Supro (Open A), 8string VanderDonck Frypan (Buddy Emmons's C6).

Mike K

1935 A22 Rickenbacher Frypan (C6), 1937 7string Prewar Rickenbacher Bakelite (C Diatonic), 1937 7string Epiphone Electar (Jerry Byrd's E9), 1937 Epiphone Electar (C#m9), 1940's Post War Rickenbacher Bakelite (Feet's D), 1950 Supro (Open F), 1950's Rickenbacher ACE (C6), 1950's Rickenbacher A25 Frypan (A6), 1957 National New Yorker (Jerry's E13), 1955 Q8 Fender Stringmaster (A6, C6, Noel's E13, C Diatonic), 1961 Supro (Open A), 8string VanderDonck Frypan (Buddy Emmons's C6).

-

Brad Bechtel

- Moderator

- Posts: 8559

- Joined: 4 Aug 1998 11:00 pm

- Location: San Francisco, CA

- State/Province: California

- Country: United States

Moved from Electronics to Steel Without Pedals. I think longtime member Rick Aiello may be able to answer your questions.

Brad’s Page of Steel

A web site devoted to acoustic & electric lap steel guitars

A web site devoted to acoustic & electric lap steel guitars

-

Rick Aiello

- Posts: 4999

- Joined: 11 Sep 2000 12:01 am

- Location: Berryville, VA USA

- State/Province: -

- Country: United States

You need a high carbon tool steel … bend it, drill (8-32 , 6-32) grind , then any finish work that needs doing before the next step …. Now the important part … it must be heat treated (hardened) for the steel to retain magnetism (austenite must be converted into martensite) …

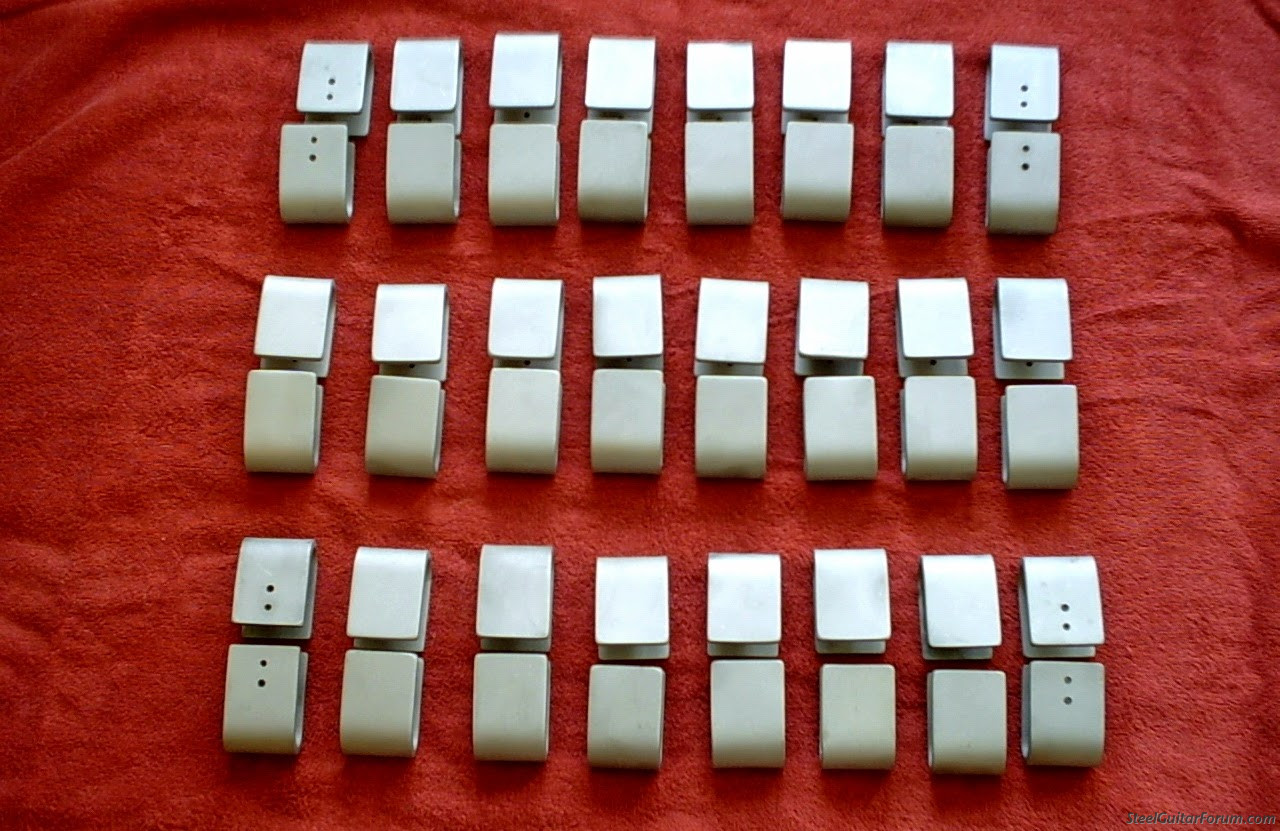

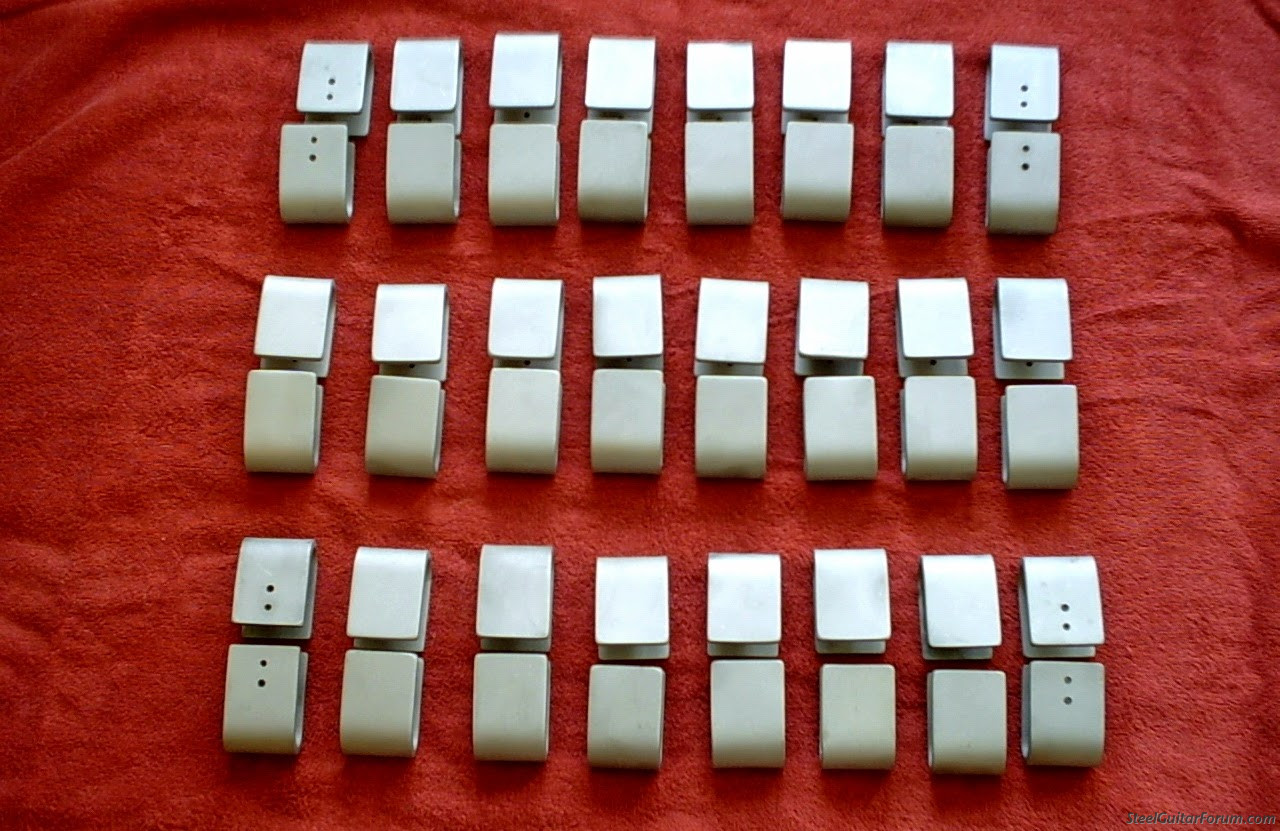

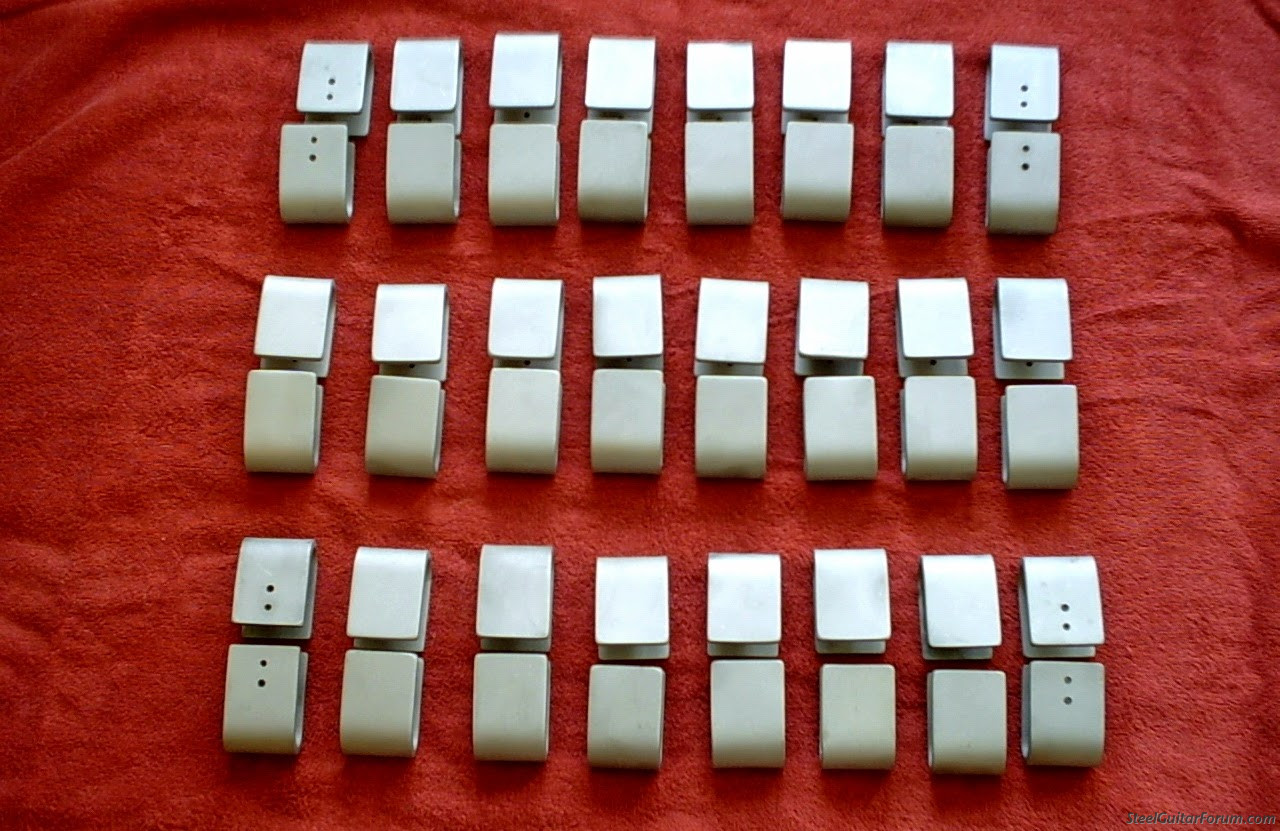

Here was the first batch I ever made Lollar ...

Here was the first batch I ever made Lollar ...

-

David Laveau

- Posts: 64

- Joined: 1 Feb 2023 8:53 pm

- Location: Rocky Mountain High, CO

- State/Province: -

- Country: United States

Amazing the knowledge around these parts,Rick Aiello wrote:You need a high carbon tool steel … bend it, drill (8-32 , 6-32) grind , then any finish work that needs doing before the next step …. Now the important part … it must be heat treated (hardened) for the steel to retain magnetism (austenite must be converted into martensite) …

Here was the first batch I ever made Lollar ...

not to even mention how helpful.

Folks who are both a Scholar and a gentleman are rare birdsbirds anymore methinks.

Tip of the hat to you good sir

_______________

Just here learning

as much as I can...

Just here learning

as much as I can...

-

Michael Kiese

- Posts: 490

- Joined: 17 Jul 2023 12:27 pm

- Location: Richmond, Virginia (Hometown: Pearl City, HI)

- State/Province: West Virginia

- Country: United States

Aloha Rick,

Thank you for your reply!

Wow, I did not realize you supplied Lollar with the horseshoe magnets. Super cool!

You mentioned the high carbon tool steel as the starting bar material for the magnet...

Steel is primarily iron and carbon, correct? But there could be other elements added for alloys depending on the properties desired and manufacturing cost.

What type of Steel alloy do you think the original Rickenbacher horseshoe magnets were made of?

Follow up question: the horseshoe magnets in a Ricky are oriented to repel each other, which degausses them over time. Conversely, if they were set to attract each other, they could support each other's magnetic fields. Why do you think the repel orientation was chosen over the attract orientation?

Thanks!

Thank you for your reply!

Wow, I did not realize you supplied Lollar with the horseshoe magnets. Super cool!

You mentioned the high carbon tool steel as the starting bar material for the magnet...

Steel is primarily iron and carbon, correct? But there could be other elements added for alloys depending on the properties desired and manufacturing cost.

What type of Steel alloy do you think the original Rickenbacher horseshoe magnets were made of?

Follow up question: the horseshoe magnets in a Ricky are oriented to repel each other, which degausses them over time. Conversely, if they were set to attract each other, they could support each other's magnetic fields. Why do you think the repel orientation was chosen over the attract orientation?

Thanks!

Aloha,

Mike K

1935 A22 Rickenbacher Frypan (C6), 1937 7string Prewar Rickenbacher Bakelite (C Diatonic), 1937 7string Epiphone Electar (Jerry Byrd's E9), 1937 Epiphone Electar (C#m9), 1940's Post War Rickenbacher Bakelite (Feet's D), 1950 Supro (Open F), 1950's Rickenbacher ACE (C6), 1950's Rickenbacher A25 Frypan (A6), 1957 National New Yorker (Jerry's E13), 1955 Q8 Fender Stringmaster (A6, C6, Noel's E13, C Diatonic), 1961 Supro (Open A), 8string VanderDonck Frypan (Buddy Emmons's C6).

Mike K

1935 A22 Rickenbacher Frypan (C6), 1937 7string Prewar Rickenbacher Bakelite (C Diatonic), 1937 7string Epiphone Electar (Jerry Byrd's E9), 1937 Epiphone Electar (C#m9), 1940's Post War Rickenbacher Bakelite (Feet's D), 1950 Supro (Open F), 1950's Rickenbacher ACE (C6), 1950's Rickenbacher A25 Frypan (A6), 1957 National New Yorker (Jerry's E13), 1955 Q8 Fender Stringmaster (A6, C6, Noel's E13, C Diatonic), 1961 Supro (Open A), 8string VanderDonck Frypan (Buddy Emmons's C6).

-

Rick Aiello

- Posts: 4999

- Joined: 11 Sep 2000 12:01 am

- Location: Berryville, VA USA

- State/Province: -

- Country: United States

They have to be oriented like that … the other way keeps the lines of force within the steel magnet … and you want to magnetize the strings.

The good Rickys were cobalt tungsten steel … don’t know the percent. Epiphone horseshoes were higher in cobalt … you can tell using a gauss meter.

They don’t make blanks of cobalt steel (we never found it … short of having tons made overseas … ha ha) anymore … the rise of alnico made cobalt steel magnets obsolete…

Anyway, any good tool steel with a high carbon content is fine … the heat treat is the important thing … Rickys are super hard … and brittle

The good Rickys were cobalt tungsten steel … don’t know the percent. Epiphone horseshoes were higher in cobalt … you can tell using a gauss meter.

They don’t make blanks of cobalt steel (we never found it … short of having tons made overseas … ha ha) anymore … the rise of alnico made cobalt steel magnets obsolete…

Anyway, any good tool steel with a high carbon content is fine … the heat treat is the important thing … Rickys are super hard … and brittle

-

Michael Kiese

- Posts: 490

- Joined: 17 Jul 2023 12:27 pm

- Location: Richmond, Virginia (Hometown: Pearl City, HI)

- State/Province: West Virginia

- Country: United States

Ah, that makes a lot of sense! Thanks!Rick Aiello wrote:They have to be oriented like that … the other way keeps the lines of force within the steel magnet … and you want to magnetize the strings.

My personal little crazy science experiment would be to take 2 flat magnets like the one pictured, put them in a press brake, and try to make a rudimentary horseshoe pickup. Perhaps I could use the ones already bent into horseshoes, but then the issue is figuring out how to secure them into place in a repelling orientation.

I think the horseshoe pickup design is pretty incredible in how simple it is, but also how efficient it is.

Since the metal plates surround the strings, much more of the magnetic lines of force are focused around the strings. This gives Horseshoe pups higher output than modern single coils despite less coil windings.

It's a really cool design. It's a shame that it lost out to other pickup designs. Probably because it takes up real estate in the playing area of the string.

Aloha,

Mike K

1935 A22 Rickenbacher Frypan (C6), 1937 7string Prewar Rickenbacher Bakelite (C Diatonic), 1937 7string Epiphone Electar (Jerry Byrd's E9), 1937 Epiphone Electar (C#m9), 1940's Post War Rickenbacher Bakelite (Feet's D), 1950 Supro (Open F), 1950's Rickenbacher ACE (C6), 1950's Rickenbacher A25 Frypan (A6), 1957 National New Yorker (Jerry's E13), 1955 Q8 Fender Stringmaster (A6, C6, Noel's E13, C Diatonic), 1961 Supro (Open A), 8string VanderDonck Frypan (Buddy Emmons's C6).

Mike K

1935 A22 Rickenbacher Frypan (C6), 1937 7string Prewar Rickenbacher Bakelite (C Diatonic), 1937 7string Epiphone Electar (Jerry Byrd's E9), 1937 Epiphone Electar (C#m9), 1940's Post War Rickenbacher Bakelite (Feet's D), 1950 Supro (Open F), 1950's Rickenbacher ACE (C6), 1950's Rickenbacher A25 Frypan (A6), 1957 National New Yorker (Jerry's E13), 1955 Q8 Fender Stringmaster (A6, C6, Noel's E13, C Diatonic), 1961 Supro (Open A), 8string VanderDonck Frypan (Buddy Emmons's C6).

-

Jean Vanhees

- Posts: 5

- Joined: 12 Jun 2023 8:17 am

- Location: Belgium

- State/Province: -

- Country: United States

Hello Michael,

I have been trying to make these horse-shoe pickups now for at least 5 years.

My objective was the sound of Bobby Ingano Sleepwalk from the album Steel reflections.

In the book from Mario Milan 'pickups windings and magnets' many pickups are described, also the famous Rickenbacher horse shoe pickup.

Apparently it is +/- 5000 windings of 38 AWG.

I own a NS48 Rickenbacher lapsteel, and the DC resistance is 2.05 Kohm.

It sounds great but not like the pre WW2 Rickenbacher frypans that were 1"1/2 wide.

At some point i had the courage to open up my Rickenbacher, and found some newspapers from 1946 in the neck of the lap steel.

Then i took all the measurements from the pickup and got to try and make some of these.

From the measurement i took, the length of the pole pieces have an interval of 0.5 mm so 15mm 15.5 16 16.5 17 17.5

The pole pieces where 3mm diameter.

The u shaped magnets made for Lollar should be O1 tool steel which are high carbon steels between 0.85 and 1 % of carbon.

Because i live in Belgium, the equivalent of O1 tool steel is 1.2510.

Then i have bought several flat bar tool steels of 5mm x 40 mm to see how they would sound.

For example 1.2510 1.2099 1.2379 1.2436 Rigor sleipner, all alloy tool steels, where some of them with a higher carbon content then 1% , which you can not bend without breaking or pre heating first.

O1 or 1.2510 tool steel you can bend with an hydraulic press without pre heating.

I used a rod of 20 mm to press them to shape.

Make sure you make the holes and threats before you harden them.

I have tried a lot, hardening, anealing, and tempering with different temperatures, and magnetized them but it did not make much difference in sound.

Also i could not get them magnetized as hard as the Original Rickenbacher i own.

So i waist ed a lot of money and time.

Then i focused on the pole pieces.

I have used from weak iron of a transformer core to high carbon steel nails, and everything in between.

Then i tried a chrome rod 5mm from a toilet paper holder as pole pieces, and, believe it or not that made more difference than all the heat treatments and steel properties.

I am very close to the sound i want now, but not quit there yet....listen to link below.

The only lap steels i know of that come close to the original pre war frying pan sound are the ones from Clinesmith, but importing them to Europe is way to expansive for me.

My guess is steel with more tungsten (W element) in it could do the trick, but also a professional magnetiser.

Maybe i try 1.3207 steel, it has 9.5 % of wolfram/tungsten in it.

I hope this helped.

Let us know if you have found something and good luck.

Jean

https://drive.google.com/drive/folders/ ... drive_link

I have been trying to make these horse-shoe pickups now for at least 5 years.

My objective was the sound of Bobby Ingano Sleepwalk from the album Steel reflections.

In the book from Mario Milan 'pickups windings and magnets' many pickups are described, also the famous Rickenbacher horse shoe pickup.

Apparently it is +/- 5000 windings of 38 AWG.

I own a NS48 Rickenbacher lapsteel, and the DC resistance is 2.05 Kohm.

It sounds great but not like the pre WW2 Rickenbacher frypans that were 1"1/2 wide.

At some point i had the courage to open up my Rickenbacher, and found some newspapers from 1946 in the neck of the lap steel.

Then i took all the measurements from the pickup and got to try and make some of these.

From the measurement i took, the length of the pole pieces have an interval of 0.5 mm so 15mm 15.5 16 16.5 17 17.5

The pole pieces where 3mm diameter.

The u shaped magnets made for Lollar should be O1 tool steel which are high carbon steels between 0.85 and 1 % of carbon.

Because i live in Belgium, the equivalent of O1 tool steel is 1.2510.

Then i have bought several flat bar tool steels of 5mm x 40 mm to see how they would sound.

For example 1.2510 1.2099 1.2379 1.2436 Rigor sleipner, all alloy tool steels, where some of them with a higher carbon content then 1% , which you can not bend without breaking or pre heating first.

O1 or 1.2510 tool steel you can bend with an hydraulic press without pre heating.

I used a rod of 20 mm to press them to shape.

Make sure you make the holes and threats before you harden them.

I have tried a lot, hardening, anealing, and tempering with different temperatures, and magnetized them but it did not make much difference in sound.

Also i could not get them magnetized as hard as the Original Rickenbacher i own.

So i waist ed a lot of money and time.

Then i focused on the pole pieces.

I have used from weak iron of a transformer core to high carbon steel nails, and everything in between.

Then i tried a chrome rod 5mm from a toilet paper holder as pole pieces, and, believe it or not that made more difference than all the heat treatments and steel properties.

I am very close to the sound i want now, but not quit there yet....listen to link below.

The only lap steels i know of that come close to the original pre war frying pan sound are the ones from Clinesmith, but importing them to Europe is way to expansive for me.

My guess is steel with more tungsten (W element) in it could do the trick, but also a professional magnetiser.

Maybe i try 1.3207 steel, it has 9.5 % of wolfram/tungsten in it.

I hope this helped.

Let us know if you have found something and good luck.

Jean

https://drive.google.com/drive/folders/ ... drive_link

-

Michael Kiese

- Posts: 490

- Joined: 17 Jul 2023 12:27 pm

- Location: Richmond, Virginia (Hometown: Pearl City, HI)

- State/Province: West Virginia

- Country: United States

Re: Making a Horseshoe Magnet

Aloha Jean,

Thank you so much for that in depth reply!

Like I mentioned above, my Jan Van der Donck 8 string frypan really sounds great. It has the quintessential sound. I'm amazed that he had fabricated the whole thing.

That said, I'm completely confident that a good horseshoe pickup can be made anywhere.

It's funny that you mentioned using metal from a toilet paper holder as pole pieces...when I have taken apart my Rickenbacher Horseshoe pickups, the pole pieces appear to be metal nails that have had their ends cut off and filed down! Using a magnifying glass, that's what it literally looks like to me. Haha.

I purchased a Digital Gauss meter and started taking measurements of the magnets... From what you and Rick offered in this conversation, I hypothesize that the actual magnetic field and the force of that field probably matters more than the specific type of Tool Steel or Cobalt tungsten steel.

I have a few Rickenbacher Bakelites, and one A25 Frypan. All of the magnets have different gauss levels. Also interestingly enough, the A25 which I recently purchased had a horseshoe pup that was very degaussed so I had no choice but to remagnetize/recharge the magnet. To recharge horseshoe magnet, you just stick it on a very strong industrial magnet. I did this in Lindy Fralin's office (picture attached).

I had Lindy recharge my very first Bakelite pickup, and it ended up sounding very harsh after recharging. So ever since then, I was very hesitant to recharge any of my horseshoe magnets if they didn't need it.

Here's the interesting thing: I was forced to recharge my A25 pickup. I had no choice because the 6th string was noticeably far low in volume than the rest of the strings. It was not gig-worthy. Before recharging, the gauss reading was approx 600 gauss on polepiece 1, and 700 gauss on polepiece 6. AFTER recharging, it was 920 gauss at pp 1 and 870 gauss at pp 6. Also of note, the magnetic field is STRONGER with the bobbin of copper wire installed. On their own before recharging, one horseshoe measured 300 gauss, and the other 400 gauss.

So the maximum magnetic "charge" my A25 pickup can take is around 900 gauss per horseshoe (with bobbin installed). But my Bakelite horseshoe measures around 1100 gauss. It is very harsh sounding.

I have a Rickenbacher ACE that is my main gigging steel (it sounds amazing). It is completely dialed in, and I put 100K Ohm pots for both tone and volume. Gauss readings are 900 and 750.

So my conclusion (with small sample size) is that Rickenbacher, especially in the early days of the 30's through the 40's probably was not big on quality control. They simply were using what was available at the time, pumping out guitars by hand, and magic happened. Frypans and Bakelites were just really well designed, and they got lucky with the material choice available. Even back in the 30's and 40's, each horseshoe pickup likely sounded different simply because of different gauss values. The magnet manufacture probably wasn't standardized within any type of tolerance for gauss values.

All said and done I at least identified that I like a gauss range of 900-750 (each individual magnet). I also discovered that any gauss reading below 700 is likely going to result in low volume on the outer strings.

Furthermore, Horseshoe pickups are very efficient single coils with high output (despite low amount of copper winds). They are naturally loud, clear, and harsh. As a player, I'm always trying to reduce their "bite". Therefore, I counteracted that harshness by experimenting with different Ohm values for the pots. A 100K ohm value potentiometer is what I settled on. It allows more of the harsh high end in the signal to bleed to ground before the signal heads to the amplifier. This goes a long way in taming a Horseshoe without messing with tone capacitor values.

I have decade boxes for resistance and capacitance. I was thinking about hooking it up to my steels just to easily test different a wide range of values at once. Still haven't gotten around to it. The 100K pots I put in there did the trick on my ACE.

With my Bakelite, it's around 1100 gauss at polepiece 1 and 920 gauss at polepiece 6. It's a VERY HOT and harsh sounding pickup. I'll most likely have to use a lower value resistance Pot on it to help tame that high end. Maybe 50K or less. I'll probably get around to using the decade box approach. It is my "backup" steel so I haven't gotten around to it yet. lol. Too busy playing.

So if you haven't tried experimenting with different Pot values and capacitor values on the horseshoe pickups you have made, I highly encourage you to try! I'm sure if you did that, you'd dial in the sound you're looking for.

Decade boxes aren't expensive. You could easily attach them in-between the hot signal path and your output jack.

Use the Resistance Decade box first to determine what Ohm value you like best for the volume pot. Then use the Capacitance decade box on your tone pot to see which value you like for tone.

It's a simple and elegant solution that doesn't require metal work, and it makes a HUGE difference in tone!

Thank you so much for that in depth reply!

Like I mentioned above, my Jan Van der Donck 8 string frypan really sounds great. It has the quintessential sound. I'm amazed that he had fabricated the whole thing.

That said, I'm completely confident that a good horseshoe pickup can be made anywhere.

It's funny that you mentioned using metal from a toilet paper holder as pole pieces...when I have taken apart my Rickenbacher Horseshoe pickups, the pole pieces appear to be metal nails that have had their ends cut off and filed down! Using a magnifying glass, that's what it literally looks like to me. Haha.

I purchased a Digital Gauss meter and started taking measurements of the magnets... From what you and Rick offered in this conversation, I hypothesize that the actual magnetic field and the force of that field probably matters more than the specific type of Tool Steel or Cobalt tungsten steel.

I have a few Rickenbacher Bakelites, and one A25 Frypan. All of the magnets have different gauss levels. Also interestingly enough, the A25 which I recently purchased had a horseshoe pup that was very degaussed so I had no choice but to remagnetize/recharge the magnet. To recharge horseshoe magnet, you just stick it on a very strong industrial magnet. I did this in Lindy Fralin's office (picture attached).

I had Lindy recharge my very first Bakelite pickup, and it ended up sounding very harsh after recharging. So ever since then, I was very hesitant to recharge any of my horseshoe magnets if they didn't need it.

Here's the interesting thing: I was forced to recharge my A25 pickup. I had no choice because the 6th string was noticeably far low in volume than the rest of the strings. It was not gig-worthy. Before recharging, the gauss reading was approx 600 gauss on polepiece 1, and 700 gauss on polepiece 6. AFTER recharging, it was 920 gauss at pp 1 and 870 gauss at pp 6. Also of note, the magnetic field is STRONGER with the bobbin of copper wire installed. On their own before recharging, one horseshoe measured 300 gauss, and the other 400 gauss.

So the maximum magnetic "charge" my A25 pickup can take is around 900 gauss per horseshoe (with bobbin installed). But my Bakelite horseshoe measures around 1100 gauss. It is very harsh sounding.

I have a Rickenbacher ACE that is my main gigging steel (it sounds amazing). It is completely dialed in, and I put 100K Ohm pots for both tone and volume. Gauss readings are 900 and 750.

So my conclusion (with small sample size) is that Rickenbacher, especially in the early days of the 30's through the 40's probably was not big on quality control. They simply were using what was available at the time, pumping out guitars by hand, and magic happened. Frypans and Bakelites were just really well designed, and they got lucky with the material choice available. Even back in the 30's and 40's, each horseshoe pickup likely sounded different simply because of different gauss values. The magnet manufacture probably wasn't standardized within any type of tolerance for gauss values.

All said and done I at least identified that I like a gauss range of 900-750 (each individual magnet). I also discovered that any gauss reading below 700 is likely going to result in low volume on the outer strings.

Furthermore, Horseshoe pickups are very efficient single coils with high output (despite low amount of copper winds). They are naturally loud, clear, and harsh. As a player, I'm always trying to reduce their "bite". Therefore, I counteracted that harshness by experimenting with different Ohm values for the pots. A 100K ohm value potentiometer is what I settled on. It allows more of the harsh high end in the signal to bleed to ground before the signal heads to the amplifier. This goes a long way in taming a Horseshoe without messing with tone capacitor values.

I have decade boxes for resistance and capacitance. I was thinking about hooking it up to my steels just to easily test different a wide range of values at once. Still haven't gotten around to it. The 100K pots I put in there did the trick on my ACE.

With my Bakelite, it's around 1100 gauss at polepiece 1 and 920 gauss at polepiece 6. It's a VERY HOT and harsh sounding pickup. I'll most likely have to use a lower value resistance Pot on it to help tame that high end. Maybe 50K or less. I'll probably get around to using the decade box approach. It is my "backup" steel so I haven't gotten around to it yet. lol. Too busy playing.

So if you haven't tried experimenting with different Pot values and capacitor values on the horseshoe pickups you have made, I highly encourage you to try! I'm sure if you did that, you'd dial in the sound you're looking for.

Decade boxes aren't expensive. You could easily attach them in-between the hot signal path and your output jack.

Use the Resistance Decade box first to determine what Ohm value you like best for the volume pot. Then use the Capacitance decade box on your tone pot to see which value you like for tone.

It's a simple and elegant solution that doesn't require metal work, and it makes a HUGE difference in tone!

You do not have the required permissions to view the files attached to this post.

Aloha,

Mike K

1935 A22 Rickenbacher Frypan (C6), 1937 7string Prewar Rickenbacher Bakelite (C Diatonic), 1937 7string Epiphone Electar (Jerry Byrd's E9), 1937 Epiphone Electar (C#m9), 1940's Post War Rickenbacher Bakelite (Feet's D), 1950 Supro (Open F), 1950's Rickenbacher ACE (C6), 1950's Rickenbacher A25 Frypan (A6), 1957 National New Yorker (Jerry's E13), 1955 Q8 Fender Stringmaster (A6, C6, Noel's E13, C Diatonic), 1961 Supro (Open A), 8string VanderDonck Frypan (Buddy Emmons's C6).

Mike K

1935 A22 Rickenbacher Frypan (C6), 1937 7string Prewar Rickenbacher Bakelite (C Diatonic), 1937 7string Epiphone Electar (Jerry Byrd's E9), 1937 Epiphone Electar (C#m9), 1940's Post War Rickenbacher Bakelite (Feet's D), 1950 Supro (Open F), 1950's Rickenbacher ACE (C6), 1950's Rickenbacher A25 Frypan (A6), 1957 National New Yorker (Jerry's E13), 1955 Q8 Fender Stringmaster (A6, C6, Noel's E13, C Diatonic), 1961 Supro (Open A), 8string VanderDonck Frypan (Buddy Emmons's C6).

-

Rick Aiello

- Posts: 4999

- Joined: 11 Sep 2000 12:01 am

- Location: Berryville, VA USA

- State/Province: -

- Country: United States

Re: Making a Horseshoe Magnet

That’s because the air gap is much shorter due to the height of the pole piece …Also of note, the magnetic field is STRONGER with the bobbin of copper wire installed

Me and my electromagnet have remagnetized literally hundreds of Ricky magnets over the last 25+ years … mostly from a service I ran called “Maggin’ for b0b “ … fundraiser for the SGF.

When I take a measurement … I never include the bobbin … placing my probe mid-gap between the upper and lower flanges … They have come in from 20% down to completely dead.

They all seem to fall into one of four categories , once fully saturated.

Early prewars … around 200 gauss mid-gap

Late prewars … around 225 gauss mid-gap

T-loo era - around 250 gauss midgap

60’s era (no more NOS cobalt) - 120 gauss

Trotmore horseshoes - around 150 gauss

Epiphone horseshoes - the strongest at a whopping 350 gauss

I’ve had a couple Jan’s - still got a couple of his wound bobbins … around 140 gauss

The alloy I used for Lollar’s - 150 gauss

These are averages (I keep track of such things

Frank Ford started making them for Lollar after the first “Cease and Desist” from RIC International scared me away …

Here’s a nice article about his adventures in horseshoe making … http://www.frets.com/HomeShopTech/Produ ... shoes.html

-

Tony Oresteen

- Posts: 843

- Joined: 8 May 2017 7:54 pm

- Location: Georgia, USA

- State/Province: Georgia

- Country: United States

Re: Making a Horseshoe Magnet

My advice is to buy a new one from Jason. It will save you time and frustration. And buy a spare.

Tony

Newnan, GA

Too many guitars, not enough time to play

'72 Sho-Bud 6139, '71 Marlen 210

'78 Fender Stringmaster Quad black

PedalMaster D8

Newnan, GA

Too many guitars, not enough time to play

'72 Sho-Bud 6139, '71 Marlen 210

'78 Fender Stringmaster Quad black

PedalMaster D8

-

Michael Kiese

- Posts: 490

- Joined: 17 Jul 2023 12:27 pm

- Location: Richmond, Virginia (Hometown: Pearl City, HI)

- State/Province: West Virginia

- Country: United States

Re: Making a Horseshoe Magnet

Hi Tony,Tony Oresteen wrote: 19 Feb 2025 11:48 am My advice is to buy a new one from Jason. It will save you time and frustration. And buy a spare.

My intention is to perform home science and physics experiments purely to satisfy my own curiosity.

I still enjoy discovering how things work. Learning something new still gives me the same exact feeling of excitement as it did when I was a kid.

It just how I enjoy.

Take care!

Aloha,

Mike K

1935 A22 Rickenbacher Frypan (C6), 1937 7string Prewar Rickenbacher Bakelite (C Diatonic), 1937 7string Epiphone Electar (Jerry Byrd's E9), 1937 Epiphone Electar (C#m9), 1940's Post War Rickenbacher Bakelite (Feet's D), 1950 Supro (Open F), 1950's Rickenbacher ACE (C6), 1950's Rickenbacher A25 Frypan (A6), 1957 National New Yorker (Jerry's E13), 1955 Q8 Fender Stringmaster (A6, C6, Noel's E13, C Diatonic), 1961 Supro (Open A), 8string VanderDonck Frypan (Buddy Emmons's C6).

Mike K

1935 A22 Rickenbacher Frypan (C6), 1937 7string Prewar Rickenbacher Bakelite (C Diatonic), 1937 7string Epiphone Electar (Jerry Byrd's E9), 1937 Epiphone Electar (C#m9), 1940's Post War Rickenbacher Bakelite (Feet's D), 1950 Supro (Open F), 1950's Rickenbacher ACE (C6), 1950's Rickenbacher A25 Frypan (A6), 1957 National New Yorker (Jerry's E13), 1955 Q8 Fender Stringmaster (A6, C6, Noel's E13, C Diatonic), 1961 Supro (Open A), 8string VanderDonck Frypan (Buddy Emmons's C6).

-

Michael Kiese

- Posts: 490

- Joined: 17 Jul 2023 12:27 pm

- Location: Richmond, Virginia (Hometown: Pearl City, HI)

- State/Province: West Virginia

- Country: United States

Re: Making a Horseshoe Magnet

Hey Rick,

Thank you very much for sharing your data and measuring practices! I've definitely taken them as notes.

Also, thank you for providing Frank Ford's web link. I'll take a look at it.

It's such a shame that RIC International sent you a "Cease and Desist" letter. Just a weak attempt to bully and scare the little guy that is doing something completely legal.

The August 10, 1937 patent that George Beauchamp was awarded on the design of the frypan expired on August 10, 1954. Back then, patents were only awarded for 17 years. There is no way such a patent could still be legally enforced. It has EXPIRED.

George Beauchamp's patent has quite literally been expired for a lifetime. It's been quietly sitting in the public domain for over 70 years.

Here's the proof:

https://patents.google.com/patent/US2089171A/en

I also looked up the patent on the USPTO's website for good measure. It's still in their records. According to US Law at the time of awarding the patent, it is indeed expired.

Outside of the *threat* of waging lawfare to drain finances (of both plaintiff and defendant), there is no legal enforcement of an expired patent. If they took anyone to court, ultimately RIC Int'l would lose and look like a bunch of jerks. There's no upside for them for doing anything other than making an empty threat. Cease and Desist letters are only enforceable by the owner of a copyright, trademark, or patent. They mean nothing if the copyright, trademark, or patent is EXPIRED.

So we're free to tinker! Yay! That's what the public domain is intended for. Yipee! lol.

I'd wager that Clinesmith and Lollar are just claiming public domain and telling RIC international to go pound sand. Rightfully so.

Thank you very much for sharing your data and measuring practices! I've definitely taken them as notes.

Also, thank you for providing Frank Ford's web link. I'll take a look at it.

It's such a shame that RIC International sent you a "Cease and Desist" letter. Just a weak attempt to bully and scare the little guy that is doing something completely legal.

The August 10, 1937 patent that George Beauchamp was awarded on the design of the frypan expired on August 10, 1954. Back then, patents were only awarded for 17 years. There is no way such a patent could still be legally enforced. It has EXPIRED.

George Beauchamp's patent has quite literally been expired for a lifetime. It's been quietly sitting in the public domain for over 70 years.

Here's the proof:

https://patents.google.com/patent/US2089171A/en

I also looked up the patent on the USPTO's website for good measure. It's still in their records. According to US Law at the time of awarding the patent, it is indeed expired.

Outside of the *threat* of waging lawfare to drain finances (of both plaintiff and defendant), there is no legal enforcement of an expired patent. If they took anyone to court, ultimately RIC Int'l would lose and look like a bunch of jerks. There's no upside for them for doing anything other than making an empty threat. Cease and Desist letters are only enforceable by the owner of a copyright, trademark, or patent. They mean nothing if the copyright, trademark, or patent is EXPIRED.

So we're free to tinker! Yay! That's what the public domain is intended for. Yipee! lol.

I'd wager that Clinesmith and Lollar are just claiming public domain and telling RIC international to go pound sand. Rightfully so.

You do not have the required permissions to view the files attached to this post.

Last edited by Michael Kiese on 19 Feb 2025 1:46 pm, edited 3 times in total.

Aloha,

Mike K

1935 A22 Rickenbacher Frypan (C6), 1937 7string Prewar Rickenbacher Bakelite (C Diatonic), 1937 7string Epiphone Electar (Jerry Byrd's E9), 1937 Epiphone Electar (C#m9), 1940's Post War Rickenbacher Bakelite (Feet's D), 1950 Supro (Open F), 1950's Rickenbacher ACE (C6), 1950's Rickenbacher A25 Frypan (A6), 1957 National New Yorker (Jerry's E13), 1955 Q8 Fender Stringmaster (A6, C6, Noel's E13, C Diatonic), 1961 Supro (Open A), 8string VanderDonck Frypan (Buddy Emmons's C6).

Mike K

1935 A22 Rickenbacher Frypan (C6), 1937 7string Prewar Rickenbacher Bakelite (C Diatonic), 1937 7string Epiphone Electar (Jerry Byrd's E9), 1937 Epiphone Electar (C#m9), 1940's Post War Rickenbacher Bakelite (Feet's D), 1950 Supro (Open F), 1950's Rickenbacher ACE (C6), 1950's Rickenbacher A25 Frypan (A6), 1957 National New Yorker (Jerry's E13), 1955 Q8 Fender Stringmaster (A6, C6, Noel's E13, C Diatonic), 1961 Supro (Open A), 8string VanderDonck Frypan (Buddy Emmons's C6).

-

Rick Aiello

- Posts: 4999

- Joined: 11 Sep 2000 12:01 am

- Location: Berryville, VA USA

- State/Province: -

- Country: United States

Re: Making a Horseshoe Magnet

No … there was a lawsuit … they claimed the horseshoe pickup was a Trademark …

Lollar and RIC settled out of court … sealed

Lollar and RIC settled out of court … sealed

-

Michael Kiese

- Posts: 490

- Joined: 17 Jul 2023 12:27 pm

- Location: Richmond, Virginia (Hometown: Pearl City, HI)

- State/Province: West Virginia

- Country: United States

Re: Making a Horseshoe Magnet

Maybe RIC Int’l argued that the look of horseshoe pickups are “trade dress”, therefore associated with their brand. It could be an avenue to use Trademark to protect expired patents.Rick Aiello wrote: 19 Feb 2025 1:35 pm No … there was a lawsuit … they claimed the horseshoe pickup was a Trademark …

Lollar and RIC settled out of court … sealed

In any case, RIC int’l sounds like they are a bunch of vipers.

Imagine if Leo Fender made that same argument for the modern single coil design. No one could make any type of after market boutique pickups. Seymour Duncan, Lindy Fralin, Jason Lollar, Van Zandt, they’d all get sued.

Who knows. Maybe Fender did sue others for trade dress of their single coil pups but never had any success.

Anyways, thanks for the insight. Learned a few things I didn’t know.

Knowing how RIC Int’l does business, I don’t ever plan to support any purchases of modern Rickenbacker products.

I never cared for their guitars anyway. If they still manufactured horseshoe pickup replacements for their old steels, that’d be one thing. But it sounds like they don’t want to manufacture horseshoe pups for steels, and they don’t want anybody else to either. They just want control.

I checked their website and they sell horseshoe pups for their bass guitars for $200 (limit 1 per customer). Lol. They are so poorly managed!

If it wasn’t for their old steels, I wouldn’t give them the time of day, and they don’t make money off reselling of vintage gear. Good.

In any case now we know why Lollar charges $600 for a horseshoe pup…he’s paying off his out of court settlement with those crooks at Rickenbacher.

Aloha,

Mike K

1935 A22 Rickenbacher Frypan (C6), 1937 7string Prewar Rickenbacher Bakelite (C Diatonic), 1937 7string Epiphone Electar (Jerry Byrd's E9), 1937 Epiphone Electar (C#m9), 1940's Post War Rickenbacher Bakelite (Feet's D), 1950 Supro (Open F), 1950's Rickenbacher ACE (C6), 1950's Rickenbacher A25 Frypan (A6), 1957 National New Yorker (Jerry's E13), 1955 Q8 Fender Stringmaster (A6, C6, Noel's E13, C Diatonic), 1961 Supro (Open A), 8string VanderDonck Frypan (Buddy Emmons's C6).

Mike K

1935 A22 Rickenbacher Frypan (C6), 1937 7string Prewar Rickenbacher Bakelite (C Diatonic), 1937 7string Epiphone Electar (Jerry Byrd's E9), 1937 Epiphone Electar (C#m9), 1940's Post War Rickenbacher Bakelite (Feet's D), 1950 Supro (Open F), 1950's Rickenbacher ACE (C6), 1950's Rickenbacher A25 Frypan (A6), 1957 National New Yorker (Jerry's E13), 1955 Q8 Fender Stringmaster (A6, C6, Noel's E13, C Diatonic), 1961 Supro (Open A), 8string VanderDonck Frypan (Buddy Emmons's C6).

-

Rick Aiello

- Posts: 4999

- Joined: 11 Sep 2000 12:01 am

- Location: Berryville, VA USA

- State/Province: -

- Country: United States

Re: Making a Horseshoe Magnet

We made the 1.5”-ers for a few years , selling them for $300 a unit . Folks were pleased to have them available again. He then wanted to make 1.25” bass units. That’s when it all went downhill fast …

You do not have the required permissions to view the files attached to this post.

-

Michael Kiese

- Posts: 490

- Joined: 17 Jul 2023 12:27 pm

- Location: Richmond, Virginia (Hometown: Pearl City, HI)

- State/Province: West Virginia

- Country: United States

Re: Making a Horseshoe Magnet

Ahh, that makes sense!!! They only really cared about the bass horseshoe pups.Rick Aiello wrote: 20 Feb 2025 1:18 am We made the 1.5”-ers for a few years , selling them for $300 a unit . Folks were pleased to have them available again. He then wanted to make 1.25” bass units. That’s when it all went downhill fast …

Still kinda dumb if you ask me. They pretty much abandoned their best product, lap steels (both the bakelites and they frypans).

There still is a market for them and we are all forced to find vintage gear, or make them ourselves.

Rickenbacker doesn’t want to make new steels or replacement horseshoe pups for steels, and they don’t want anyone else to make them either.

It’s so counter productive, self defeating, and un-American. There’s a need in the market that customers are willing to pay $3K-7K for vintage and boutique lap steels…and they don’t want to fulfill that need even though they’d make money.

Pretty dumb. What a poorly mismanaged company. I literally never have met anyone in my entire life who owned much less gigged a Rickenbacker guitar.

I think one time on YouTube I saw a Filipino Beatles cover band, and one guy had a Rickenbacker. One. LMAO.

They're pretty good though. I had a hard time finding a clip with a Rickenbacker in it. So apparently it doesn't get played much. lol.

https://www.youtube.com/watch?v=ztU3HWBjTXk

Aloha,

Mike K

1935 A22 Rickenbacher Frypan (C6), 1937 7string Prewar Rickenbacher Bakelite (C Diatonic), 1937 7string Epiphone Electar (Jerry Byrd's E9), 1937 Epiphone Electar (C#m9), 1940's Post War Rickenbacher Bakelite (Feet's D), 1950 Supro (Open F), 1950's Rickenbacher ACE (C6), 1950's Rickenbacher A25 Frypan (A6), 1957 National New Yorker (Jerry's E13), 1955 Q8 Fender Stringmaster (A6, C6, Noel's E13, C Diatonic), 1961 Supro (Open A), 8string VanderDonck Frypan (Buddy Emmons's C6).

Mike K

1935 A22 Rickenbacher Frypan (C6), 1937 7string Prewar Rickenbacher Bakelite (C Diatonic), 1937 7string Epiphone Electar (Jerry Byrd's E9), 1937 Epiphone Electar (C#m9), 1940's Post War Rickenbacher Bakelite (Feet's D), 1950 Supro (Open F), 1950's Rickenbacher ACE (C6), 1950's Rickenbacher A25 Frypan (A6), 1957 National New Yorker (Jerry's E13), 1955 Q8 Fender Stringmaster (A6, C6, Noel's E13, C Diatonic), 1961 Supro (Open A), 8string VanderDonck Frypan (Buddy Emmons's C6).

-

Ian Worley

- Posts: 2420

- Joined: 14 Jan 2012 12:02 pm

- Location: Sacramento, CA

- State/Province: California

- Country: United States

Re: Making a Horseshoe Magnet

A question for Rick Aiello, slightly off-topic so my apologies to the OP, but speaking of Rickenbacker bass pickups... I have an old horseshoe pickup from a '63 4000 bass that I would love to restore. I've had the bass since 1978, the pickup was DOA with an open coil so I just put a jazz bass pickup in it and threw the original in drawer. The horseshoe magnets are now pretty dead.

Is this something you would you be able to revive? As you can see in the pic, the nickel plating is in bad shape too. I'm also curious if can be stripped and restored, and whether plating affects how or when in the process the magnetism is re-applied? I would assume that would all need to be done first. There is a local guy here, Jerry Sentell, who can rewind the coil, but obviously no point in doing that without working magnets.

Is this something you would you be able to revive? As you can see in the pic, the nickel plating is in bad shape too. I'm also curious if can be stripped and restored, and whether plating affects how or when in the process the magnetism is re-applied? I would assume that would all need to be done first. There is a local guy here, Jerry Sentell, who can rewind the coil, but obviously no point in doing that without working magnets.

You do not have the required permissions to view the files attached to this post.

All lies and jest, still a man hears what he wants to hear and disregards the rest - Paul Simon

-

Rick Aiello

- Posts: 4999

- Joined: 11 Sep 2000 12:01 am

- Location: Berryville, VA USA

- State/Province: -

- Country: United States

Re: Making a Horseshoe Magnet

They would plate them first … then remagnetize them after that is done …

They really aren’t that rusty … you could just polish them up and remagnetize …

The 60’s horseshoes are not known for the their strength … but it is a nice piece

They really aren’t that rusty … you could just polish them up and remagnetize …

The 60’s horseshoes are not known for the their strength … but it is a nice piece

-

Michael Kiese

- Posts: 490

- Joined: 17 Jul 2023 12:27 pm

- Location: Richmond, Virginia (Hometown: Pearl City, HI)

- State/Province: West Virginia

- Country: United States

Re: Making a Horseshoe Magnet

Hi Ian,Ian Worley wrote: 20 Feb 2025 2:15 pm

Is this something you would you be able to revive? As you can see in the pic, the nickel plating is in bad shape too. I'm also curious if can be stripped and restored, and whether plating affects how or when in the process the magnetism is re-applied? I would assume that would all need to be done first. There is a local guy here, Jerry Sentell, who can rewind the coil, but obviously no point in doing that without working magnets.

I concur with Rick. Just remagnetize the horseshoes. It will probably still work. Horseshoe magnets are a rudimentary type of magnet and they naturally degauss (lose their magnetism) over time. The magnets aren't as strong as modern magnets, and they're also set up to oppose (push against) each other, which naturally degausses each other over time.

In order to remagnetize them, you just stick them onto a VERY strong (industrial) permanent magnet.

Pictured here is Lindy Fralin charging one of my Horseshoe magnets with the industrial permanent magnet he uses to align the poles of all his pickups after winding them. It's right next to his desk.

The magnet you need must have a separate north and south pole. Literally all you do is stick the horseshoe on the strong magnet, and let it sit for a few seconds. That's it. It's now recharged. Lindy told me the magnet in the picture is industrial strength. He uses it all the time, and it's high quality and will last forever. It's a couple hundred dollars (good metal is expensive). As for magnet options for you, maybe try purchasing a pair of neodymium magnets on Amazon? That might work. Rick would know. You have nothing to lose by trying it, and it'll be a fun home experiment.

Or, just send it to Rick, and he can recharge it with his electromagnet (super cool stuff).

You most likely do not need to rewind the bobbin (as long as both ends of the copper wire are intact). The Bobbin is just comprised of metal polepieces and copper wire. Not much to go bad there. Also Lindy recommends to never attempt to open up the bobbins on an old horseshoe pickup, especially the old ones. They just crumble and fall apart. Save yourself the headache. Lindy said his shop stopped rewinding old horseshoe pups because of their tendency to fall apart. So unless one or both of the copper leads are broken, don't bother rewinding or opening the bobbin. It's a can of worms.

Good luck!

You do not have the required permissions to view the files attached to this post.

Aloha,

Mike K

1935 A22 Rickenbacher Frypan (C6), 1937 7string Prewar Rickenbacher Bakelite (C Diatonic), 1937 7string Epiphone Electar (Jerry Byrd's E9), 1937 Epiphone Electar (C#m9), 1940's Post War Rickenbacher Bakelite (Feet's D), 1950 Supro (Open F), 1950's Rickenbacher ACE (C6), 1950's Rickenbacher A25 Frypan (A6), 1957 National New Yorker (Jerry's E13), 1955 Q8 Fender Stringmaster (A6, C6, Noel's E13, C Diatonic), 1961 Supro (Open A), 8string VanderDonck Frypan (Buddy Emmons's C6).

Mike K

1935 A22 Rickenbacher Frypan (C6), 1937 7string Prewar Rickenbacher Bakelite (C Diatonic), 1937 7string Epiphone Electar (Jerry Byrd's E9), 1937 Epiphone Electar (C#m9), 1940's Post War Rickenbacher Bakelite (Feet's D), 1950 Supro (Open F), 1950's Rickenbacher ACE (C6), 1950's Rickenbacher A25 Frypan (A6), 1957 National New Yorker (Jerry's E13), 1955 Q8 Fender Stringmaster (A6, C6, Noel's E13, C Diatonic), 1961 Supro (Open A), 8string VanderDonck Frypan (Buddy Emmons's C6).

-

Rick Aiello

- Posts: 4999

- Joined: 11 Sep 2000 12:01 am

- Location: Berryville, VA USA

- State/Province: -

- Country: United States

Re: Making a Horseshoe Magnet

I know a nice trick … using a 2” x 1” x 1/8” neodymium magnet … maybe I’ll put it up on YouTube …

No need for any hardware… just the magnet … got to have strong fingers though

No need for any hardware… just the magnet … got to have strong fingers though

-

Michael Kiese

- Posts: 490

- Joined: 17 Jul 2023 12:27 pm

- Location: Richmond, Virginia (Hometown: Pearl City, HI)

- State/Province: West Virginia

- Country: United States

Re: Making a Horseshoe Magnet

NICE!!! Sensei Rick for da win!!! I look forward to watching that video!Rick Aiello wrote: 20 Feb 2025 6:12 pm I know a nice trick … using a 2” x 1” x 1/8” neodymium magnet … maybe I’ll put it up on YouTube …

No need for any hardware… just the magnet … got to have strong fingers though

Aloha,

Mike K

1935 A22 Rickenbacher Frypan (C6), 1937 7string Prewar Rickenbacher Bakelite (C Diatonic), 1937 7string Epiphone Electar (Jerry Byrd's E9), 1937 Epiphone Electar (C#m9), 1940's Post War Rickenbacher Bakelite (Feet's D), 1950 Supro (Open F), 1950's Rickenbacher ACE (C6), 1950's Rickenbacher A25 Frypan (A6), 1957 National New Yorker (Jerry's E13), 1955 Q8 Fender Stringmaster (A6, C6, Noel's E13, C Diatonic), 1961 Supro (Open A), 8string VanderDonck Frypan (Buddy Emmons's C6).

Mike K

1935 A22 Rickenbacher Frypan (C6), 1937 7string Prewar Rickenbacher Bakelite (C Diatonic), 1937 7string Epiphone Electar (Jerry Byrd's E9), 1937 Epiphone Electar (C#m9), 1940's Post War Rickenbacher Bakelite (Feet's D), 1950 Supro (Open F), 1950's Rickenbacher ACE (C6), 1950's Rickenbacher A25 Frypan (A6), 1957 National New Yorker (Jerry's E13), 1955 Q8 Fender Stringmaster (A6, C6, Noel's E13, C Diatonic), 1961 Supro (Open A), 8string VanderDonck Frypan (Buddy Emmons's C6).

-

Rick Aiello

- Posts: 4999

- Joined: 11 Sep 2000 12:01 am

- Location: Berryville, VA USA

- State/Province: -

- Country: United States

Re: Making a Horseshoe Magnet

Here’s the trick :

https://youtu.be/G8v8-Nc_Yy4?si=pk5qv9uMMh3LgbO2

Here is the NIB … $3 …

https://www.magnet4less.com/n45-rare-ea ... n-x-1-8-in

https://youtu.be/G8v8-Nc_Yy4?si=pk5qv9uMMh3LgbO2

Here is the NIB … $3 …

https://www.magnet4less.com/n45-rare-ea ... n-x-1-8-in

-

Michael Kiese

- Posts: 490

- Joined: 17 Jul 2023 12:27 pm

- Location: Richmond, Virginia (Hometown: Pearl City, HI)

- State/Province: West Virginia

- Country: United States

Re: Making a Horseshoe Magnet

Mahalo Rick! I see we are both night owls. LOL!Rick Aiello wrote: 20 Feb 2025 10:36 pm Here’s the trick :

https://youtu.be/G8v8-Nc_Yy4?si=pk5qv9uMMh3LgbO2

Here is the NIB … $3 …

https://www.magnet4less.com/n45-rare-ea ... n-x-1-8-in

Aloha,

Mike K

1935 A22 Rickenbacher Frypan (C6), 1937 7string Prewar Rickenbacher Bakelite (C Diatonic), 1937 7string Epiphone Electar (Jerry Byrd's E9), 1937 Epiphone Electar (C#m9), 1940's Post War Rickenbacher Bakelite (Feet's D), 1950 Supro (Open F), 1950's Rickenbacher ACE (C6), 1950's Rickenbacher A25 Frypan (A6), 1957 National New Yorker (Jerry's E13), 1955 Q8 Fender Stringmaster (A6, C6, Noel's E13, C Diatonic), 1961 Supro (Open A), 8string VanderDonck Frypan (Buddy Emmons's C6).

Mike K

1935 A22 Rickenbacher Frypan (C6), 1937 7string Prewar Rickenbacher Bakelite (C Diatonic), 1937 7string Epiphone Electar (Jerry Byrd's E9), 1937 Epiphone Electar (C#m9), 1940's Post War Rickenbacher Bakelite (Feet's D), 1950 Supro (Open F), 1950's Rickenbacher ACE (C6), 1950's Rickenbacher A25 Frypan (A6), 1957 National New Yorker (Jerry's E13), 1955 Q8 Fender Stringmaster (A6, C6, Noel's E13, C Diatonic), 1961 Supro (Open A), 8string VanderDonck Frypan (Buddy Emmons's C6).

-

Ian Worley

- Posts: 2420

- Joined: 14 Jan 2012 12:02 pm

- Location: Sacramento, CA

- State/Province: California

- Country: United States

Re: Making a Horseshoe Magnet

Thanks Rick for that cool demonstration! I will take your advice give it a whirl.

As for the pickup coil, it will need a rewind. It was already toast before I acquired the bass in '78, the inner winding lead was sheared off at the face of the bobbin. The bass was only about 15 years old at that time, it had no case and may have been exposed to some harsh conditions - the nickel plating on the magnets and cast tailpiece was already blistering at that point, something that hasn't actually changed or worsened in the 47 years since. Per Michael's comment on the potential fragility of the bobbin, it may turn out to be a fool's errand to attempt a rewind, but that coil is of no value as it is so I might as well give it a try. Worst case I can just have Jerry Sentell build a replica from scratch. It's a cool old bass and it would be nice to get it back to (somewhat) original.

Oops, another off-topic post! Thanks again Rick and Michael for the help and advice !

As for the pickup coil, it will need a rewind. It was already toast before I acquired the bass in '78, the inner winding lead was sheared off at the face of the bobbin. The bass was only about 15 years old at that time, it had no case and may have been exposed to some harsh conditions - the nickel plating on the magnets and cast tailpiece was already blistering at that point, something that hasn't actually changed or worsened in the 47 years since. Per Michael's comment on the potential fragility of the bobbin, it may turn out to be a fool's errand to attempt a rewind, but that coil is of no value as it is so I might as well give it a try. Worst case I can just have Jerry Sentell build a replica from scratch. It's a cool old bass and it would be nice to get it back to (somewhat) original.

Oops, another off-topic post! Thanks again Rick and Michael for the help and advice !

You do not have the required permissions to view the files attached to this post.

All lies and jest, still a man hears what he wants to hear and disregards the rest - Paul Simon