Stepper Motor Pedal Steel

Moderator: J D Sauser

- Georg Sørtun

- Posts: 3854

- Joined: 2 Jun 2009 9:12 am

- Location: Mandal, Agder, Norway

- Contact:

- b0b

- Posts: 29084

- Joined: 4 Aug 1998 11:00 pm

- Location: Cloverdale, CA, USA

- Contact:

1-String Electro-mechanical Changer Contest

If someone wants to volunteer to manage such a contest, feel free to start a new topic about it with some rules and a deadline. The Forum can award some sort of plaque or trophy to the winner(s).

-𝕓𝕆𝕓- (admin) - Robert P. Lee - Recordings - Breathe - D6th - Video

- Karlis Abolins

- Posts: 736

- Joined: 30 Mar 2002 1:01 am

- Location: (near) Seattle, WA, USA

I don't know about running an actual contest but I have an interest in experimenting with the concept.

I visualize a scenario where the result has the following requirements:

The string should have a scale length of 24 - 25 inches.

A candidate pitch would be the 4th string E on the E9th tuning.

The demo should have the string raise a half step and a full step (F and F#) and the string lower a half step and a full step (D# and D). This should be selectively controlled by software.

The pedal end of the demo should show the full range of up and down for the raises and lowers.

I think that there is room for partial experiments by individuals who are interested in either the string pitch change or the pedal AD process but not necessarily interested in the whole process - virtual (computer animated) pedal and real string setup and vice versa.

My own approach would be phased. I would concentrate on the string side and control it with a virtual pedal to demonstrate proof-of-concept and then develop the pedal. I think I favor a Raspberry Pi for the control center and virtual pedal since I already have one connected to my 3d printer. There is a lot of information available on using the Raspberry Pi in an experimental setting including control of stepper motors.

So, regardless of an official contest, I think I will go ahead with a prototype.

Karlis

I visualize a scenario where the result has the following requirements:

The string should have a scale length of 24 - 25 inches.

A candidate pitch would be the 4th string E on the E9th tuning.

The demo should have the string raise a half step and a full step (F and F#) and the string lower a half step and a full step (D# and D). This should be selectively controlled by software.

The pedal end of the demo should show the full range of up and down for the raises and lowers.

I think that there is room for partial experiments by individuals who are interested in either the string pitch change or the pedal AD process but not necessarily interested in the whole process - virtual (computer animated) pedal and real string setup and vice versa.

My own approach would be phased. I would concentrate on the string side and control it with a virtual pedal to demonstrate proof-of-concept and then develop the pedal. I think I favor a Raspberry Pi for the control center and virtual pedal since I already have one connected to my 3d printer. There is a lot of information available on using the Raspberry Pi in an experimental setting including control of stepper motors.

So, regardless of an official contest, I think I will go ahead with a prototype.

Karlis

- b0b

- Posts: 29084

- Joined: 4 Aug 1998 11:00 pm

- Location: Cloverdale, CA, USA

- Contact:

Raspberry Pi is a good platform for controller software, and it's only $35.

-𝕓𝕆𝕓- (admin) - Robert P. Lee - Recordings - Breathe - D6th - Video

- Bob Sykes

- Posts: 276

- Joined: 16 Nov 2009 2:23 pm

- Location: North Carolina

Emi

This idea is certainly possible and if not practical, it's still a great concept to experiment with.

Something that has not come up on this or previous discussions is noise. Not the kind that I make playing pedal steel, but electrical noise. Steppers, servos and solenoids all generate substantial magnetic fields. Less obvious is the similar noise created by digital electronics. Unfortunately guitar pickups are great at converting this noise into audio. Try holding your smartphone, tablet or even a LED flashlight next to your PSG pickup. Shielding against these magnetic fields can be difficult. I expect the electronics/actuators should be located away from the pickup(s). Possibly at the keyhead?

A conventional changer may not be needed anyway on such a guitar. Motorized tuning keys might work. Sort of like what Gibson did on their 6-strings.

Something that has not come up on this or previous discussions is noise. Not the kind that I make playing pedal steel, but electrical noise. Steppers, servos and solenoids all generate substantial magnetic fields. Less obvious is the similar noise created by digital electronics. Unfortunately guitar pickups are great at converting this noise into audio. Try holding your smartphone, tablet or even a LED flashlight next to your PSG pickup. Shielding against these magnetic fields can be difficult. I expect the electronics/actuators should be located away from the pickup(s). Possibly at the keyhead?

A conventional changer may not be needed anyway on such a guitar. Motorized tuning keys might work. Sort of like what Gibson did on their 6-strings.

Carters Starter, D10 8+7, SD10, Chandler RH-2, Rogue RLS-1

ISO Sustainus Ad Infinitum

ISO Sustainus Ad Infinitum

-

Dennis Olearchik

- Posts: 382

- Joined: 24 Jul 2001 12:01 am

- Location: Newtown, PA

- Eric Moon

- Posts: 38

- Joined: 30 Sep 2015 7:37 am

- Location: Colorado, USA

- Contact:

- Mitchell Smithey

- Posts: 291

- Joined: 1 Jun 2011 9:33 am

- Location: Dallas, USA

Tech moves so fast that it’s only a matter of time before this idea plays out. I don’t expect it would play or sound exactly like what we are used to. Our most common tunings and setups are dictated as much by the mechanical limits of the instrument as the musical. We go to great lengths to compensate for those limitations with compensators, tuning temperaments and so on. Imagine not having to deal with all that mechanically....

The pedal steel is the already the whackiest instrument ever invented, lets keep pushing it to the limit!

The pedal steel is the already the whackiest instrument ever invented, lets keep pushing it to the limit!

- Georg Sørtun

- Posts: 3854

- Joined: 2 Jun 2009 9:12 am

- Location: Mandal, Agder, Norway

- Contact:

Agree. Although electrical noise is not much of a problem – close to 100% screening is possible. I would focus more on preventing mechanical noise from servos from spreading through the instrument body and reach the strings and PU.Eric Moon wrote:It seems like the best way to deal with electrical noise is to pull from the nut. I know Glenn built one of his Moyos that way to experiment with different bridge materials... it moves the servos quite a ways from the pickups.

Pulling from behind the nut would help to achieve mechanical as well as electrical dampening, so building the changer as part of the keyhead / "keyless" setup sure will make the contraption more "noiseless" in every respect.

-

Jim Kennedy

- Posts: 500

- Joined: 13 Jul 2007 3:05 pm

- Location: Brentwood California, USA

I would think a midi controller and software dedicated exclusively to pedal steel might be an alternative. The physical aspects would remain, while the variations in tunings and copedants would be limitless, handled by software. Add in amp Sims and effects, you could conceivably end up with a light weight rig that would need only a good amp.

ShoBud Pro 1, 75 Tele, 85 Yamaha SA 2000, Fender Cybertwin,

- Chance Wilson

- Posts: 208

- Joined: 26 Jan 2002 1:01 am

- Location: South Cal, USA

- James W Smith

- Posts: 4

- Joined: 11 Sep 2020 12:13 pm

- Location: Tennessee, USA

Stepper motor PSG

I'm new here, so please don't start the flames yet.... But why not change the pitch without changing the string tension. Pitch shifters are available for electric guitar, so Why couldn't that technology be used for PSG? Something like the Electro-Harmonix Pitch Fork.

Emmons LeGrande II - 1999

-

Benjamin Davidson

- Posts: 223

- Joined: 27 Apr 2018 1:17 pm

Using a digital pitch shift effect wouldnt give the right feel. It would sound digital for one thing, second, isolating each individual strings frequency for pitch shift, without bleed over wouldnt be easily accomplished.

Pulling from the nut would isolate mechanical noise. As far as mimicing the squeeze pedals and levers. I feel a programmed solinoid could be the way to go. A set of solinoids manipulating a keyless tuning system could be programmed to make this work. Calibration would provide its own challenges to such a system.

Pulling from the nut would isolate mechanical noise. As far as mimicing the squeeze pedals and levers. I feel a programmed solinoid could be the way to go. A set of solinoids manipulating a keyless tuning system could be programmed to make this work. Calibration would provide its own challenges to such a system.

Justice Pro-Lite (9p9k) 10 String D13th Universal Tuning

-

Bobby D. Jones

- Posts: 2986

- Joined: 17 May 2010 9:27 am

- Location: West Virginia, USA

About 50 years ago in 1970 when I built my steel guitar. I worked in the light bulb industry. There was a electrical engineer and a mechanical engineer both figured on simplifying the mechanics of a steel guitar. They studied servo units, Air pistons, eletro magnetic pulls. They even studied air pistons and Selonoid valves for movement. They came back with some ideas to move the pitch, But could only do it at one speed, Could not vary the speed of the pitch changes for each song. With modern computer controls it may be possible to vary the speed of pitch movement. Maybe by the use of the song's timing placed in a computer program to control a varied speed of pitch change for each song.

Like a wheel there may be limits to change to the original design.

Like a wheel there may be limits to change to the original design.

- Glenn Demichele

- Posts: 708

- Joined: 11 Oct 2012 8:55 am

- Location: (20mi N of) Chicago Illinois, USA

For fun, I built a one string unit using a linear solenoid. It took a lot of current! Although I could get the pitch to bend fine, I started thinking about the pedals and there’s something about the pedal feel that would be difficult to replicate. The Feel of the mechanical linkage to the string is lost, and it would be a pain to build tactile feedback into the pedals.

Franklin D10 8&5, Excel D10 8&5. Both amazing guitars! Homemade buffer/overdrive with tone and adjustable 700Hz "Fender" scoop., Moyo pedal, GT-001 effects, 2x BAM200 for stereo or spare. TT12 and BW1501 each closed back wedge. Also NV400 etc. etc...

- Karlis Abolins

- Posts: 736

- Joined: 30 Mar 2002 1:01 am

- Location: (near) Seattle, WA, USA

Re-visiting the use of stepper motors and electronic controls rather than mechanical controls, I have come to the conclusion that it is not feasible at this time. My research leads me to conclude that a stepper motor than can accommodate static torque of 30+ pounds would be prohibitively large, expensive, and noisy. It would be impossible to mount 10 or 20 such motors on a pedal steel.

I don't have enough knowledge of the other electro-mechanical devices mentioned in this thread to judge whether they would be feasible, but my guess is that we are not ready to go that route.

It appears that old-fashioned mechanical linkage is and will continue to be the best choice for pedal steel control.

The possibility of using electronic (software, midi, etc.) means of pitch change suffers from the same issues in that the control pedals and levers and their interfaces with the software suffer from technical insufficiency.

The use of midi with pedal steel is complicated by the lack of midi support for instruments that have more than 6 strings. The industry leader in analog to midi implementation, Roland, has excellent products that convert analog pitch to midi via segregated pickups but their interface to the midi control box has only 6 pins for input.

As a side issue, midi pedal steel using the Roland products lends it self to use on a 6 string pedal steel such as the steels made by Jim Flynn, Jimmie Hudson, and others.

Karlis

I don't have enough knowledge of the other electro-mechanical devices mentioned in this thread to judge whether they would be feasible, but my guess is that we are not ready to go that route.

It appears that old-fashioned mechanical linkage is and will continue to be the best choice for pedal steel control.

The possibility of using electronic (software, midi, etc.) means of pitch change suffers from the same issues in that the control pedals and levers and their interfaces with the software suffer from technical insufficiency.

The use of midi with pedal steel is complicated by the lack of midi support for instruments that have more than 6 strings. The industry leader in analog to midi implementation, Roland, has excellent products that convert analog pitch to midi via segregated pickups but their interface to the midi control box has only 6 pins for input.

As a side issue, midi pedal steel using the Roland products lends it self to use on a 6 string pedal steel such as the steels made by Jim Flynn, Jimmie Hudson, and others.

Karlis

- Ian Worley

- Posts: 2340

- Joined: 14 Jan 2012 12:02 pm

- Location: Sacramento, CA

- Karlis Abolins

- Posts: 736

- Joined: 30 Mar 2002 1:01 am

- Location: (near) Seattle, WA, USA

Ian, What a timely link! I had just posted that stepper motors were not an option when you posted the link to the servo bender guitar. The counter-force mechanism is ingenious. It is also applicable to a stepper motor implementation. Instead of having the stepper motor pulling against the whole of the 30 pound static torque of the string, it can be helped by a spring that reduces the static torque to near zero. Thus a small, fast, and quiet (and relatively inexpensive) stepper motor could be attached to each string.

I had resigned myself to giving up on this project but now I am re-energized.

Karlis

I had resigned myself to giving up on this project but now I am re-energized.

Karlis

- Ian Worley

- Posts: 2340

- Joined: 14 Jan 2012 12:02 pm

- Location: Sacramento, CA

I posted a link to that earlier in this thread, it was actually a link to a different conversation from about five years ago. If I were designing something like this for a psg, I would use a mechanical changer like what we have now. There would be no static tension on the servo at rest, it would only experience resistance when a pull was activated.

Even with a pull-release type changer setup the mechanical tension balance between the strings and return springs could be separate from whatever means you used to activate a change.

There is a mechanical advantage in a typical all-pull changer that reduces the effort needed to activate a pull by 50% or more, a crude illustration of this below.

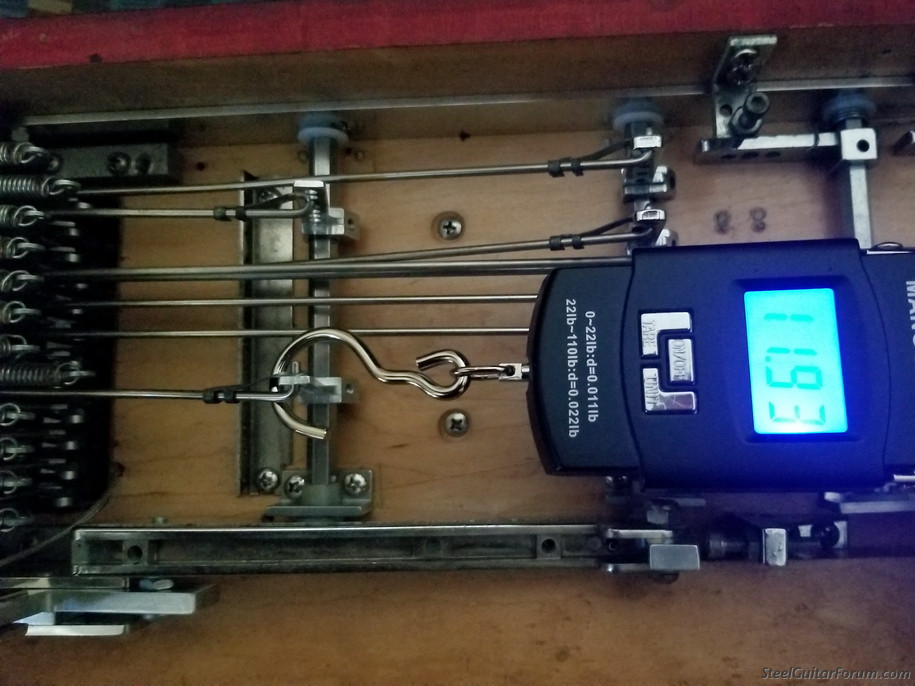

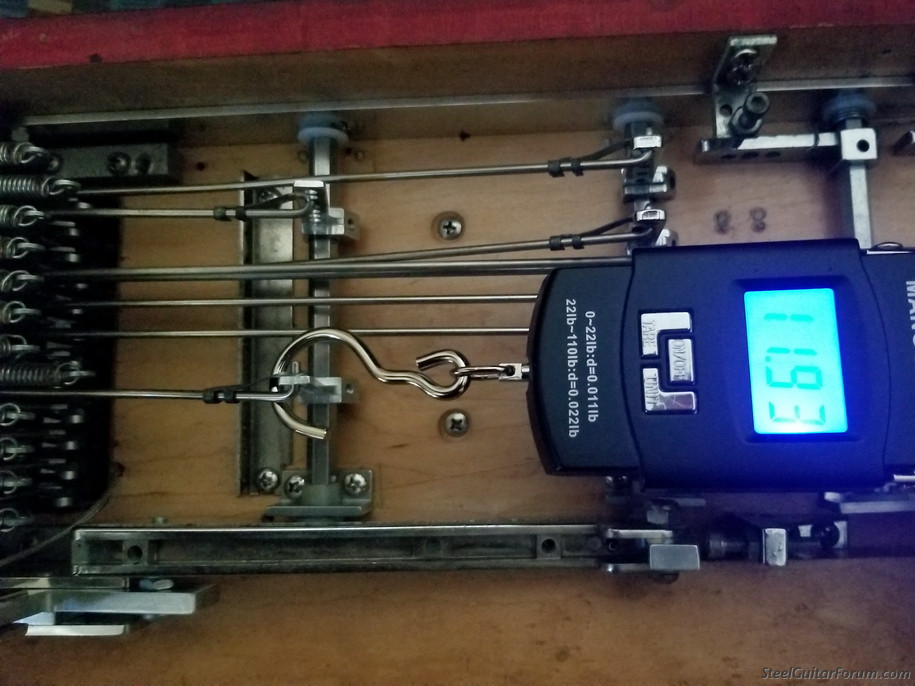

much less than the typical ~30# string tension on a psg.

Even with a pull-release type changer setup the mechanical tension balance between the strings and return springs could be separate from whatever means you used to activate a change.

There is a mechanical advantage in a typical all-pull changer that reduces the effort needed to activate a pull by 50% or more, a crude illustration of this below.

much less than the typical ~30# string tension on a psg.

- Karlis Abolins

- Posts: 736

- Joined: 30 Mar 2002 1:01 am

- Location: (near) Seattle, WA, USA

An all-pull changer would require two servos or stepper motors per string whereas a pull release (or constant pull for a better name) requires only one. In my mind the constant pull scenario requires that the device knows where neutral is. Your point that the stepper or servo on an all-pull implementation would be at rest unless engaged may or may not be significant. A constant pull mechanism clearly would require to be active the whole time. I don't know if stepper motors are rated for 100% duty cycle. That is an important avenue of inquiry.

- Georg Sørtun

- Posts: 3854

- Joined: 2 Jun 2009 9:12 am

- Location: Mandal, Agder, Norway

- Contact:

A screw drive – as I have mentioned earlier, works same as a screw jack for cars but in miniature. Basically it is a screw/nut-in-a-tube arrangement that takes the place of a pull-rod, and it does not need power to stay in place in neutral position or anywhere else along the travel.

- A screw drive can be made very narrow, and mounted as tight or tighter than distance between strings on a PSG.

- Miniature DC motors for screw drives can be staggered, so size of those isn't much of an issue. Just make any other screw drive longer than its neighbor(s).

- Pulling-power for a screw drive can be made plenty high enough even with the smallest DC motors. The "gearing" is in the screw/nut arrangement.

Whether or not to add "counterforce springs" to lessen the load on the screw/nut is a matter of choice. May make them last longer.

- Speed isn't an issue with screw drives either, as they can react as fast as anyone's mechanical pedal-push, or as slow as anyone would like.

- Whether to use screw drives in a direct pull-release setup (10 drives for 10 strings), or via all-pull scissors (20 drives for 10 strings), is a matter of choice surrounding complexity of the mechanics and of programming the controller.

Think I have included all the basics…

- A screw drive can be made very narrow, and mounted as tight or tighter than distance between strings on a PSG.

- Miniature DC motors for screw drives can be staggered, so size of those isn't much of an issue. Just make any other screw drive longer than its neighbor(s).

- Pulling-power for a screw drive can be made plenty high enough even with the smallest DC motors. The "gearing" is in the screw/nut arrangement.

Whether or not to add "counterforce springs" to lessen the load on the screw/nut is a matter of choice. May make them last longer.

- Speed isn't an issue with screw drives either, as they can react as fast as anyone's mechanical pedal-push, or as slow as anyone would like.

- Whether to use screw drives in a direct pull-release setup (10 drives for 10 strings), or via all-pull scissors (20 drives for 10 strings), is a matter of choice surrounding complexity of the mechanics and of programming the controller.

Think I have included all the basics…

- Karlis Abolins

- Posts: 736

- Joined: 30 Mar 2002 1:01 am

- Location: (near) Seattle, WA, USA

-

Bobby D. Jones

- Posts: 2986

- Joined: 17 May 2010 9:27 am

- Location: West Virginia, USA

It may be that we would have to go back too some of the first pedals being attached through the key head pulling down in the middle of the string span of the key head.

There is a physics rule about pulling sideways in the middle of a lines span. Working with the white water rafters they would run a rope from a stuck raft and a tree, Then attach a line in the middle of the rope and pull at 90 degrees to the main line. They said the got like a 7 to 1 mechanical advantage. They could pull a stuck raft out of places that could not be moved any other way with just Man/Woman Power on a river.

There is a physics rule about pulling sideways in the middle of a lines span. Working with the white water rafters they would run a rope from a stuck raft and a tree, Then attach a line in the middle of the rope and pull at 90 degrees to the main line. They said the got like a 7 to 1 mechanical advantage. They could pull a stuck raft out of places that could not be moved any other way with just Man/Woman Power on a river.

- Georg Sørtun

- Posts: 3854

- Joined: 2 Jun 2009 9:12 am

- Location: Mandal, Agder, Norway

- Contact:

Well, first of all; I would not use stepper motors for my screw drive. Regular miniature DC motors are better, faster, smaller, and less noisy, and counting steps (8-10 or more steps/revolution) with flags/optocouplers is a pretty standard method in my book.Karlis Abolins wrote:The ball screw drive combined with a stepper motor is quite an elegant solution. The only issue I see (and found mentioned) is contamination of the screw with foreign matter causing degradation of performance.

Secondly; as I envisioned having to build these "expanding/-contracting pull-rod" contraptions from scratch because of the lack of sideways space inside a PSG, the long tube with the "nut" inside rotates with the motor, while the screw inside it will not rotate, and only the slick pull-rod-like extension of the screw sticking out of the tube will be exposed to dust/dirt.

With the tube capped off with a dust-seal at one end and totally closed at the other, the assembly for each pull will have the appearance of a long and thin linear motor, with the rod for attachment to the changer sticking out at one end, and the mini-motor – which will be the thick part that may need staggering – attached at the other. As such it should be pretty dust-proof, and come out as one piece for maintenance or replacement.

- b0b

- Posts: 29084

- Joined: 4 Aug 1998 11:00 pm

- Location: Cloverdale, CA, USA

- Contact:

Would such a guitar make robot-like noises as you pushed the pedals?

-𝕓𝕆𝕓- (admin) - Robert P. Lee - Recordings - Breathe - D6th - Video