| Author |

Topic: Sho Bud changer fingers |

Rob Clot

From:

Petaluma, California USA

|

Posted 19 Oct 2016 8:07 pm

Posted 19 Oct 2016 8:07 pm |

|

Stormy, Its been a while since I had my guitar apart, so I can't say I remember exactly how the finger system works. I just remember that the levers would not return smoothly, and I don't want to take mine apart just yet. When I receive the ones from you, I will check into it further.

Thanks,

Rob |

|

|

|

Storm Rosson

From:

Silver City, NM. USA

|

Posted 19 Oct 2016 9:35 pm

Posted 19 Oct 2016 9:35 pm |

|

They should be showing up by the end of the week...Stormy  |

|

|

|

Wayne Ledbetter

From:

Arkansas, USA

|

Posted 19 Oct 2016 11:53 pm Groove in finger

Posted 19 Oct 2016 11:53 pm Groove in finger |

|

I wish some one would post a picture of the groove that the OP and others are talking about on the finger and the chrome plate fulcrum. Might be something we Sho Bud owners may need to be checking. Thanks.

_________________

Sho Bud Super Pro, Fender Twin Reissue, Martin HD-28, Gibson J-45, Gibson RB-250,Stelling Bellflower,Regal Dobro, Takamine and Alvarez Classical, Fender Telecaster, Peavey Studio Pro 112. Mainly played Gospel and some bluegrass. |

|

|

|

Edward Rhea

From:

Medford Oklahoma, USA

|

|

|

|

Wayne Ledbetter

From:

Arkansas, USA

|

Posted 20 Oct 2016 4:22 am Thanks for info

Posted 20 Oct 2016 4:22 am Thanks for info |

|

Thanks Edward for that link. I see the wear. Just not sure how it all fits together...lol.

_________________

Sho Bud Super Pro, Fender Twin Reissue, Martin HD-28, Gibson J-45, Gibson RB-250,Stelling Bellflower,Regal Dobro, Takamine and Alvarez Classical, Fender Telecaster, Peavey Studio Pro 112. Mainly played Gospel and some bluegrass. |

|

|

|

Rob Clot

From:

Petaluma, California USA

|

Posted 20 Oct 2016 8:06 am

Posted 20 Oct 2016 8:06 am |

|

| Edward, Thats a great past link on this subject. A lot of good info for other solutions. Gets the gears in my head turning!! |

|

|

|

Edward Rhea

From:

Medford Oklahoma, USA

|

Posted 20 Oct 2016 9:15 am

Posted 20 Oct 2016 9:15 am |

|

Wayne, to see the finger out of the changer housing, helps tremendously, on what's going on...to have one in your hand, where you can manipulate it actions, explains the rest?

You got it Rob! But thanking Ian Worley, for the photos/explanation, is more appropriate! |

|

|

|

John Billings

From:

Ohio, USA

|

Posted 20 Oct 2016 3:18 pm

Posted 20 Oct 2016 3:18 pm |

|

The finger in Ian's pic looks like it could be repaired with a tig welder and some filing.

_________________

Dr. Z Surgical Steel amp, amazing!

"74 Bud S-10 3&6

'73 Bud S-10 3&5(under construction)

'63 Fingertip S-10, at James awaiting 6 knees

'57 Strat, LP Blue

'91 Tele with 60's Maple neck

Dozen more guitars!

Dozens of amps, but SF Quad reverb, Rick Johnson cabs. JBL 15, '64 Vibroverb for at home.

'52 and '56 Pro Amps |

|

|

|

Storm Rosson

From:

Silver City, NM. USA

|

Posted 20 Oct 2016 4:03 pm

Posted 20 Oct 2016 4:03 pm |

|

| John, didn't someone also do some fix-its on the inside lower finger groove with JB Weld or some form of epoxy? Thinking they said it had been working OK. Can't remember how long they had been using it with epoxy fix....Stormy |

|

|

|

John Billings

From:

Ohio, USA

|

Posted 20 Oct 2016 4:10 pm

Posted 20 Oct 2016 4:10 pm |

|

" didn't someone also do some fix-its on the inside lower finger groove with JB Weld or some form of epoxy?"

I think that was my old friend Bob Metzger. I would think that tig welding in some new aluminum would be better though. Not hard to do. I have a friend who's a welder and did some repairs for me on a Performance neck that was accidentally gouged during polishing. When done, you could not even find where it had been damaged! Wouldn't cost much to fill that wear in the finger. Take a welder less than a minute to fill it.

_________________

Dr. Z Surgical Steel amp, amazing!

"74 Bud S-10 3&6

'73 Bud S-10 3&5(under construction)

'63 Fingertip S-10, at James awaiting 6 knees

'57 Strat, LP Blue

'91 Tele with 60's Maple neck

Dozen more guitars!

Dozens of amps, but SF Quad reverb, Rick Johnson cabs. JBL 15, '64 Vibroverb for at home.

'52 and '56 Pro Amps |

|

|

|

Storm Rosson

From:

Silver City, NM. USA

|

Posted 20 Oct 2016 4:30 pm

Posted 20 Oct 2016 4:30 pm |

|

| Dang John i didn't know you could weld or even hot-fill that pot metal. That would definitely be the way to go. I bought that NOS set from Russ Wever back then, wanting to find someone to make some SS bridge/fulcrum pieces to replace the pot metal stock parts...Stormy |

|

|

|

John Billings

From:

Ohio, USA

|

Posted 20 Oct 2016 4:33 pm

Posted 20 Oct 2016 4:33 pm |

|

Stormy!

Dang! I wasn't paying attention. Can you fill pot metal? I don't really know! I was thinking the finger was aluminum. Duh!

_________________

Dr. Z Surgical Steel amp, amazing!

"74 Bud S-10 3&6

'73 Bud S-10 3&5(under construction)

'63 Fingertip S-10, at James awaiting 6 knees

'57 Strat, LP Blue

'91 Tele with 60's Maple neck

Dozen more guitars!

Dozens of amps, but SF Quad reverb, Rick Johnson cabs. JBL 15, '64 Vibroverb for at home.

'52 and '56 Pro Amps |

|

|

|

Storm Rosson

From:

Silver City, NM. USA

|

Posted 20 Oct 2016 7:28 pm

Posted 20 Oct 2016 7:28 pm |

|

Maybe someone who knows the in's and out's of pot metal will jump in and enlighten us John.  |

|

|

|

Rob Clot

From:

Petaluma, California USA

|

Posted 20 Oct 2016 10:19 pm

Posted 20 Oct 2016 10:19 pm |

|

| As far as I know, pot metal is pretty much a garbage metal. Epoxy might work for a while, but I don't think it would be a solution to the problem. I've done some welding in my time, and can't remember any good ways to weld pot metal. Maybe a braze, but that would be soft too. What about applying a thin piece of Stainless to the finger? I can't wait to get a look at those pieces you sent, Storm. |

|

|

|

Clyde Lane

From:

Glasgow, Kentucky, USA

|

Posted 21 Oct 2016 4:37 am

Posted 21 Oct 2016 4:37 am |

|

Wouldn't it be better to put a bearing on the scissor? Couldn't be much harder than making a new finger.

_________________

Clyde Lane |

|

|

|

Storm Rosson

From:

Silver City, NM. USA

|

Posted 21 Oct 2016 7:52 am

Posted 21 Oct 2016 7:52 am |

|

| Then you're still left with grooveing from the strings on the fulcrum/bridge top(s). |

|

|

|

Clyde Lane

From:

Glasgow, Kentucky, USA

|

Posted 21 Oct 2016 8:18 am

Posted 21 Oct 2016 8:18 am |

|

That groove is only like 1/16" wide. I would think that a bearing would roll over that since it is going in the same direction. Or you could epoxy the grove first and it would last a lifetime.

_________________

Clyde Lane |

|

|

|

Storm Rosson

From:

Silver City, NM. USA

|

Posted 21 Oct 2016 12:56 pm

Posted 21 Oct 2016 12:56 pm |

|

| The grooves from string wear are on the top of the changer (fulcrum)and the most used strings w/pulls wear faster and eventually the strings will no longer be the same heighth. Sometimes one can dress them out with fine sandpaper if they aren't to deep, you have to make sure that all the fulcrums are the same height with a straightedge in the end...Stormy |

|

|

|

Rob Clot

From:

Petaluma, California USA

|

Posted 25 Oct 2016 8:55 pm

Posted 25 Oct 2016 8:55 pm |

|

Storm,

I just received the fingers yesterday, Thank you. Now That I've had a chance to look at them closely again, I came up with an idea to add a piece of chrome molly sheet to the finger (.025" thick). It is compatible in tensile strength to SS and about 3 times tougher than mild steel. ( And a buddy of mine just happened to have some to offer me  ). I have ordered some taps and screws. When I have one completed, I will share with you all out there. ). I have ordered some taps and screws. When I have one completed, I will share with you all out there. |

|

|

|

Storm Rosson

From:

Silver City, NM. USA

|

Posted 26 Oct 2016 11:59 am

Posted 26 Oct 2016 11:59 am |

|

Cool idea Rob ,for sure keep us posted on the process...Stormy  |

|

|

|

Ian Worley

From:

Sacramento, CA

|

Posted 26 Oct 2016 7:22 pm

Posted 26 Oct 2016 7:22 pm |

|

| Rob Clot wrote: |

| ...I have ordered some taps and screws... |

From my own experience, drilling and tapping tiny holes into 3/16" wide parts sounds like a perfect recipe for a giant cuss-storm, followed by an even larger migraine. Lots of taps broken off inside of valuable parts, mis-drilled holes, etc.

As Tom B. suggested above though, cladding that bearing surface with something hard is a good idea, even on new aluminum fingers. The chromoly material you're talking about attaching is less than 1/32" thick though, not super rigid to be sure. Perhaps you might consider attaching it with epoxy instead. It would be infinitely simpler, would provide a solid long-term bond and probably better and more stable support of the chromoly pads than a couple of tiny screws. The epoxy would likely outlast the .025" chromoly itself.

Just a thought, I'll be curious to hear how it works out. Good luck! |

|

|

|

Ken Byng

From:

Southampton, England

|

Posted 27 Oct 2016 8:19 am

Posted 27 Oct 2016 8:19 am |

|

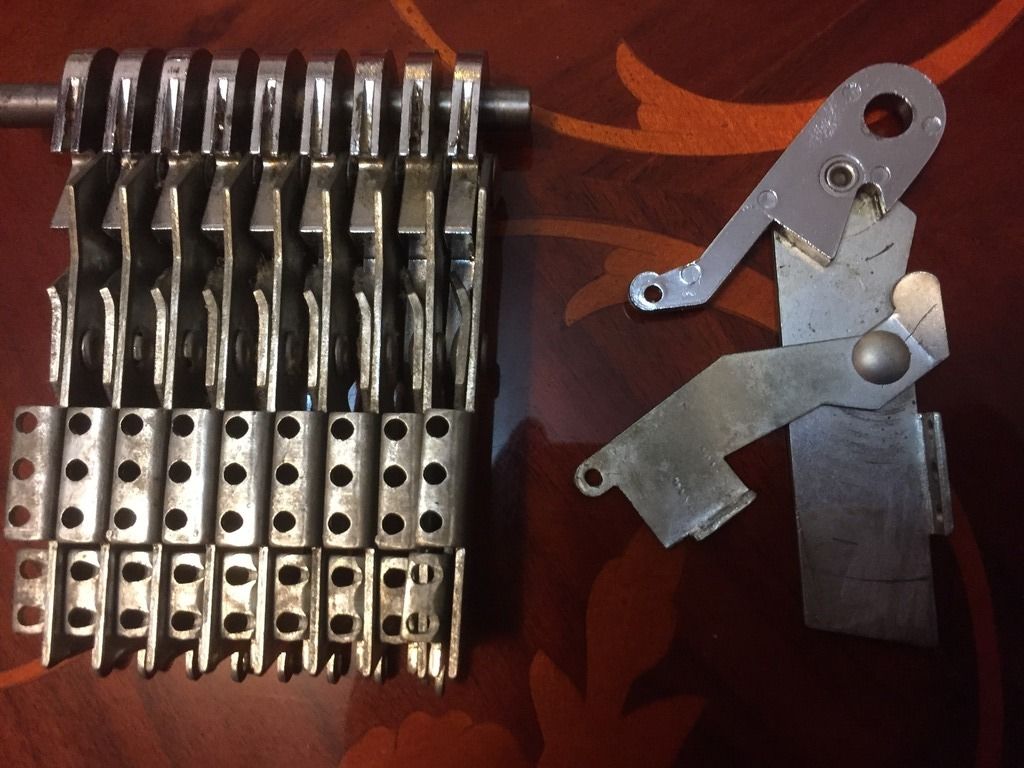

My friend Ron Mawn used to work for Sho~Bud (London) in the 70's and 80's. The company sold a large number of Bud's in the UK at that time and Ron amassed a fair amount of spares. He has gradually sold these parts off over the years, but still had a few left recently. The changer assembly below is unused and as new, and was sitting in a drawer in Ron's home. He asked me to sell it for him, and eventually it sold to a guy from Ireland. You can see the chromed top section of a finger that is separate from the rest of the assembly in the photo.

_________________

Show Pro D10 - amber (8+6), MSA D10 Legend XL Signature - redburst (9+6), Sho-Bud Pro 111 Custom (8+6), Emmons black Push-Pull D10 (8+5), Zum D10 (8x8), Hudson pedal resonator. Telonics TCA-500, Webb 614-E, |

|

|

|

Storm Rosson

From:

Silver City, NM. USA

|

Posted 27 Oct 2016 8:51 am

Posted 27 Oct 2016 8:51 am |

|

Great pics Ken, the lower finger tang is perfectly visible. I'm working on putting a ball/roller bearing on that finger as James Morehead has done on his "super fingers". Hope I can get mine to work as well as James', but ...James does great work. (me not so much)  |

|

|

|

Ken Byng

From:

Southampton, England

|

Posted 27 Oct 2016 10:12 am

Posted 27 Oct 2016 10:12 am |

|

Stormy

The modern manufacturers who put a roller bearing in their changer fingers report the changer returning to dead zero. Many engineers will say that ball bearings in an environment with minimal movement is a waste.

However, I have an Infinity guitar built by master builder Frank Carter, and the changer is as smooth as silk and has little or no hysteresis. Frank Carter puts bearings in his changer fingers, with excellent results. The changer assembly above is almost prehistoric in comparison. But it works, and my Sho~Bud Pro 111 Custom's changer fingers are still working fine after 40 odd years of action.

_________________

Show Pro D10 - amber (8+6), MSA D10 Legend XL Signature - redburst (9+6), Sho-Bud Pro 111 Custom (8+6), Emmons black Push-Pull D10 (8+5), Zum D10 (8x8), Hudson pedal resonator. Telonics TCA-500, Webb 614-E, |

|

|

|

Storm Rosson

From:

Silver City, NM. USA

|

Posted 27 Oct 2016 10:25 am

Posted 27 Oct 2016 10:25 am |

|

Thanks for the info Ken, I already ordered bearings for the lower finger mod ,and am looking at bearings for the fingers/axle mod.I think situations occur that may show some engineering principle(s) fail to include EVERY/ALL implementations that may arise....anyway thanks again Ken....Stormy  |

|

|

|