| Author |

Topic: S12 Uni build project |

Ian Rae

From:

Redditch, England

|

Posted 21 May 2014 12:50 pm

Posted 21 May 2014 12:50 pm |

|

I never thought it would be such a short time after I started to play steel and joined the forum (about six months now) that I decided to build my own guitar! Two reasons – I need a second instrument so I can tear down the one I have (an old D10) – and right from the start I’ve been curious about the universal concept. I can’t afford to buy a uni, so I’m making one. I have only a modest workshop – no lathe, although I can do a little light milling on a drill press.

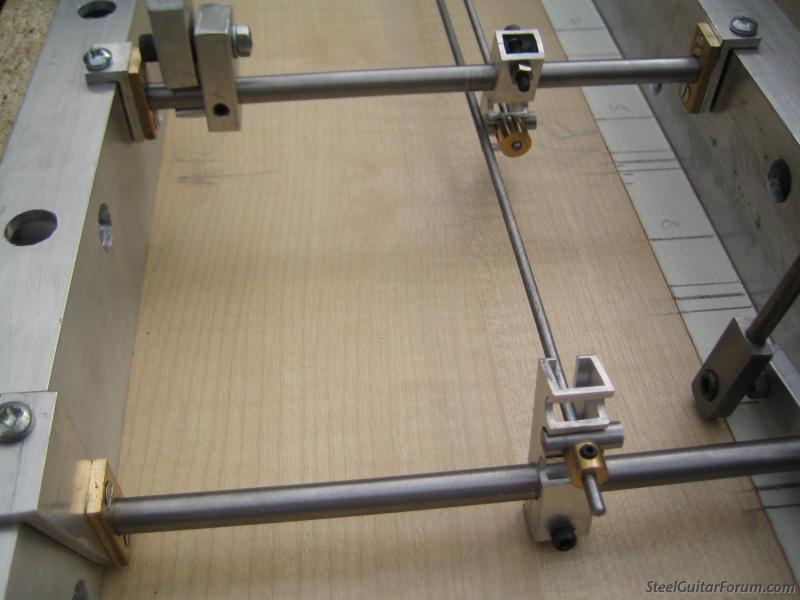

So far I’ve designed and assembled all the components necessary to build a one-string test-bed. Here are my design criteria:-

1. Changer – I don’t have the resources to make a scissor-type, and I’m certain it’s the solid fingers that give a pull-release its superior sound. I don’t need lots of different raises and lowers. So I’ve gone for a Kline-style yoke mechanism which will be deliberately massive and easy to construct. It can deliver 2R 1L or 1R 2L and will stretch to one 3R if I need it.

2. Keyless tuner – these get mixed reviews, but I can’t easily and unaided make a keyhead or a roller nut, so I’ve omitted both. My design may alleviate the string breakage that some complain of.

3. Undercarriage - it must to be easy to change the copedent, as I can’t be sure exactly what I want straight off. The mechanism must be positive and accurate.

4. Weight – don’t care. Will not hesitate to use steel instead of aluminium where it improves the sound or the mechanical action.

5. Finish – I don’t have the knowledge or enthusiasm to create gleaming motorcycles. Save money here. It’ll be functional but elegant and will look fine in subdued lighting.

Here are some pics and a mercifully short video. The screws holding the changer parts together are temporary, as is a great deal else:-

https://www.youtube.com/watch?v=UHE93iJaaoI&feature=youtu.be

All this got me thinking too – there are several (ok – a few) options in the way of beginner models of PSG, but they’re all E9 10-stringers or less. If you want to try a uni, there doesn’t seem to be an entry level below full price. A beginner guitar needs to work well and sound good; apparently this is not always the case. If my design works and can be put together at reasonable cost, I might offer it for sale over here. There must be others like me who can’t afford a full-price 12-string just to see if they like it.

Next job is to build and test a second raise on this string. Will keep you all posted as the work goes on.

_________________

Make sleeping dogs tell the truth!

Homebuilt keyless U12 7x5, Excel keyless U12 8x8, Williams keyless U12 7x8, Telonics rack and 15" cabs |

|

|

|

Dave Bertoncini

From:

Sun City West, Arizona USA

|

Posted 21 May 2014 2:48 pm

Posted 21 May 2014 2:48 pm |

|

| Looks great, good job...can't wait to see it come together |

|

|

|

Scott Duckworth

From:

Etowah, TN Western Foothills of the Smokies

|

|

|

|

Tom Gorr

From:

Three Hills, Alberta

|

Posted 21 May 2014 5:57 pm

Posted 21 May 2014 5:57 pm |

|

| Looking good! |

|

|

|

Ian Rae

From:

Redditch, England

|

Posted 22 May 2014 12:39 am

Posted 22 May 2014 12:39 am |

|

Sure thing, Scott

_________________

Make sleeping dogs tell the truth!

Homebuilt keyless U12 7x5, Excel keyless U12 8x8, Williams keyless U12 7x8, Telonics rack and 15" cabs |

|

|

|

Mike Perlowin

From:

Los Angeles CA

|

Posted 22 May 2014 3:04 am

Posted 22 May 2014 3:04 am |

|

You are right about nobody building an economy 12 string. But there are often some good used ones in the classified ads. You can get a used MSA and/or Dekley for $12-1500.

_________________

Please visit my web site and Soundcloud page and listen to the music posted there.

http://www.mikeperlowin.com http://soundcloud.com/mike-perlowin |

|

|

|

Ross Shafer

From:

Petaluma, California

|

Posted 22 May 2014 6:37 am

Posted 22 May 2014 6:37 am |

|

Cool project Ian! I get all fidgety and start to sweat when I read things like this though:

"....I can do a little light milling on a drill press."

If you like to gamble you can do that....Sorry to be Mr. Machine Shop cop, but milling (even lightly) on a drill press is not recommended at best and downright dangerous at worst.

Most drill press chucks are held attached using a simple self locking taper which works perfectly fine for cutting forces (like drilling) that transmit force straight up the drill.

Milling requires moving the cutter sideways through the material and the taper on your drill press IS NOT up to that job. I don't care how light your cuts are or how careful or alert you are. When the sideways cutting forces finally do loosen that chuck from its taper (not so much a question of if, but when) its going to happen faster than you can imagine and can ruin a nice day in the shop, trash a good chuck and/or drill press spindle and likely make you soil your shorts.

...Of course if your face or other body part is in the strike zone as the chuck wobbles its way of the spindle then goes flying....well I think you get the picture right? milling machines use a different tool holding method for a reason.

Don't ask me how I know about this. Be careful out there! |

|

|

|

Larry Bell

From:

Englewood, Florida

|

Posted 22 May 2014 7:37 am

Posted 22 May 2014 7:37 am |

|

I wish you the best of luck, Ian. I feel it incumbent on myself to make a point or two.

From a cost perspective, the S-12 universal guitar has nearly as many parts as a D-10. To get the changes which truly make it 'universal' you will need at least 6 pedals and 5 or 6 knee levers. Some changes work well on either a pedal or lever, but you will need a total of 12 or more pedals + levers, IMHO.

There is a good reason why you see economy 3x5 E9 guitars but NOT full blown U12 guitars. It's akin to asking for an economy D-10. Also, realize the limitations the changer may impose in light of the changes you really need. I play primarily Emmons original U12 guitars so I'm accustomed to the limitations a push-pull or pull-release changer can place on your copedent.

A S-12 EXTENDED E9 guitar can have far fewer pulls with full E9 functionality. This less ambitious project could serve as a jumping off point to complete the universal tuning once you've proved the concepts and worked the bugs out by building a 12-string with 3 pedals and 4 or 5 levers.

As Ross pointed out, the number of bellcranks, pedal connections, and other assorted pieces will be substantial and very difficult to pull off on a manual lathe, much less on a drill press. I'll add my plea to Ross', please be careful when milling with a drill press.

From your pictures, you clearly know what you are doing and have a good start. I wish you the best of luck and look forward to hearing how the project is progressing.

For some background info on the E9/B6 Universal tuning, I recommend you take a look at my website

http://www.larrybell.org

_________________

Larry Bell - email: larry@larrybell.org - gigs - Home Page

My CD's: 'I've Got Friends in COLD Places' - 'Pedal Steel Guitar'

2021 Rittenberry S/D-12 8x7, 1976 Emmons S/D-12 7x6, 1969 Emmons S/D-12 6x6, 1971 Dobro, Quilter ToneBlock 202 TT-12 |

|

|

|

Jerry Fessenden

From:

Vermont, USA

|

Posted 22 May 2014 7:42 am S-12 uni

Posted 22 May 2014 7:42 am S-12 uni |

|

| Hi there ...you remind me of the daus when Richie Brennion and I started to first build our project guitars . I think you have some good ideas If you need and parts , send me an email through the forum. |

|

|

|

Larry Bell

From:

Englewood, Florida

|

Posted 22 May 2014 8:44 am

Posted 22 May 2014 8:44 am |

|

By the way, Ian, JERRY'S THE BEST.

I mentioned I play old Emmons guitars -- that's the sound I look for. My only guitar that is not an Emmons is a Fessenden. For MANY REASONS. They do sound great, but, in addition, Jerry's design / mechanics are excellent and he has worked with Sho-Bud, Zane Beck, and other notable builders and pioneer steel guitar designers and innovators. Jerry's 3r3l changer and pull design are as good as any brand on the market -- and as easy to change pulls on as any I've owned.

He does have a CNC machine shop handy near his shop and has gone through many of the challenges you will face. It would be worth your effort to make friends with Jerry.

_________________

Larry Bell - email: larry@larrybell.org - gigs - Home Page

My CD's: 'I've Got Friends in COLD Places' - 'Pedal Steel Guitar'

2021 Rittenberry S/D-12 8x7, 1976 Emmons S/D-12 7x6, 1969 Emmons S/D-12 6x6, 1971 Dobro, Quilter ToneBlock 202 TT-12 |

|

|

|

Ian Rae

From:

Redditch, England

|

Posted 22 May 2014 11:37 am

Posted 22 May 2014 11:37 am |

|

Larry - everything you say is interesting, as we might expect. I've looked at your site a few times when looking for info on tunings. I take your point about the number of components - if you combine most of the musical possibilities of two necks you're going to end up with most of the hardware. I will eventually have 7 & 6, I think. But I'm undaunted by the amount of tedious manufacturing I face (my wife rather unkindly calls me obsessive, but I call it hardworking).

I see what you mean about starting with an extended E9 and adding the other changes, but I'm going to be perverse and do it the other way round  . My next step is to add 3 more strings so that I have a 4-string uni on 5 through 8, which to me is the heart of the instrument in both tunings. At this stage it will have 4 & 3 or 4 & 4. It needs to feel equally right in both styles in this area IMHO. Once I'm happy and all bugs are ironed, then I shall expand upwards and downwards into pretty much charted territory. . My next step is to add 3 more strings so that I have a 4-string uni on 5 through 8, which to me is the heart of the instrument in both tunings. At this stage it will have 4 & 3 or 4 & 4. It needs to feel equally right in both styles in this area IMHO. Once I'm happy and all bugs are ironed, then I shall expand upwards and downwards into pretty much charted territory.

As for the milling issue, what little I've done so far didn't feel comfortable. I didn't plan to use any originally and I do have a friend an hour away with a proper milling machine, so either way I can avoid it.

It's a big boost for Jerry Fessenden to have shown support, and I've told him so.

_________________

Make sleeping dogs tell the truth!

Homebuilt keyless U12 7x5, Excel keyless U12 8x8, Williams keyless U12 7x8, Telonics rack and 15" cabs |

|

|

|

Larry Bell

From:

Englewood, Florida

|

Posted 22 May 2014 11:43 am

Posted 22 May 2014 11:43 am |

|

That is just too cool for school, my friend.

(and I -- and likely many other steel players -- fully understand the obsessive/compulsive tendencies many of us seem to share)

Keep us in the loop

Godspeed

_________________

Larry Bell - email: larry@larrybell.org - gigs - Home Page

My CD's: 'I've Got Friends in COLD Places' - 'Pedal Steel Guitar'

2021 Rittenberry S/D-12 8x7, 1976 Emmons S/D-12 7x6, 1969 Emmons S/D-12 6x6, 1971 Dobro, Quilter ToneBlock 202 TT-12 |

|

|

|

Russell Adkins

From:

Louisiana, USA

|

Posted 24 May 2014 9:48 am

Posted 24 May 2014 9:48 am |

|

| Hi Ian ,I think you are doing very well on your project hope you keep it going and keep us posted . russ |

|

|

|

Ian Rae

From:

Redditch, England

|

Posted 29 May 2014 11:47 am

Posted 29 May 2014 11:47 am |

|

I have now reached the important step of a double raise (or lower).

The centre rod makes the first raise by pulling on the cutout with its pin. The top rod (bottom in the picture) leaves the pin behind as it makes the second raise. The socket screws in this mockup will eventually become 3/16" dia. plain studs. The cutout will be neater in future.

The copedent I have in mind needs only 2R - 1L or 1R - 2L. Next step is 4 strings (5-8) with E9 changes, two pedals, two knees. It'll be a while as I need to ditch the scrap timber in the temporary changer frame and make an all-metal version.

_________________

Make sleeping dogs tell the truth!

Homebuilt keyless U12 7x5, Excel keyless U12 8x8, Williams keyless U12 7x8, Telonics rack and 15" cabs |

|

|

|

Ian Rae

From:

Redditch, England

|

Posted 10 Jul 2014 7:12 am

Posted 10 Jul 2014 7:12 am |

|

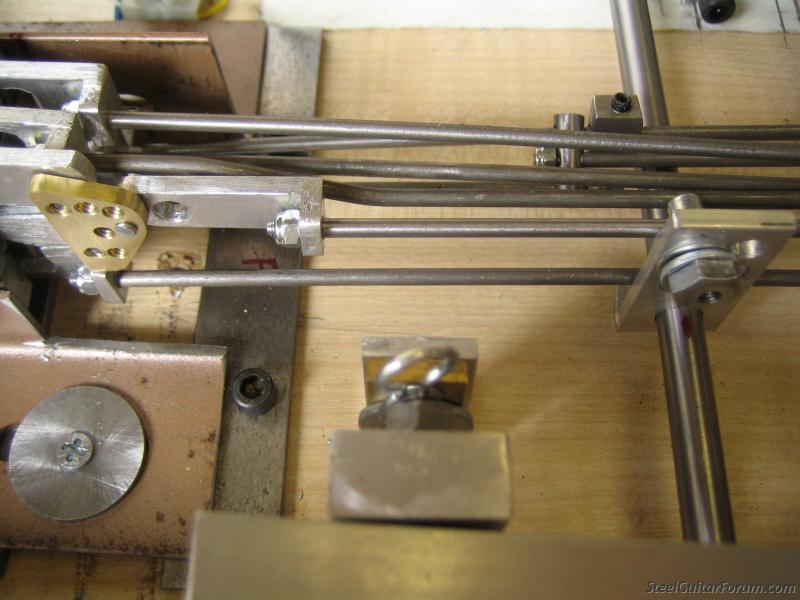

Work has been held up by unrelated matters (no-one told me that this could happen!) but the guitar now has 4 strings (5-8) and 2 pedals and 2 knees to give the basic E9 changes.

The changer is in its final form

although the endplate is temporary, but the tuner will have a thicker plate for the screws.

The shaped knee levers are a pain to make, but I like them.

There are three different types of pull crank underneath - the one that works best is the bulkiest and hardest to make, but I'm improving the small easy one.

The neck is temporary - just a piece of particle board, but it's doing a fine job of keeping the other bits away from each other. In the video, ignore the tone of the $10 pickup but see what you think of the sustain, which is quite encouraging and should improve when the temporary parts are replaced with better materials and the changer has the weight of the other 8 sections.

(There is a fair amount of pedal noise as I had the amp quite low, not because my neighbour doesn't appreciate country music, but because he does!)

https://www.youtube.com/watch?v=93ocFJEdYo0

_________________

Make sleeping dogs tell the truth!

Homebuilt keyless U12 7x5, Excel keyless U12 8x8, Williams keyless U12 7x8, Telonics rack and 15" cabs |

|

|

|

Alan Brookes

From:

Brummy living in Southern California

|

Posted 10 Jul 2014 9:51 am

Posted 10 Jul 2014 9:51 am |

|

I had the pleasure of visiting Ian at his home twice during March, which was only just over three months ago. It's amazing how far this project has come in such a short time. Also amazing is Rae's blossoming talent on pedal steel. In just a few months he's gone further than most starters go in a few years. It's no doubt helped by the fact that Rae was a professional music teacher.

Last edited by Alan Brookes on 11 Jul 2014 8:58 am; edited 1 time in total |

|

|

|

Edward Rhea

From:

Medford Oklahoma, USA

|

Posted 10 Jul 2014 6:24 pm

Posted 10 Jul 2014 6:24 pm |

|

Your project is really coming along, Ian! As is your machining!

_________________

“TONESNOB†|

|

|

|

Ian Rae

From:

Redditch, England

|

Posted 16 Jul 2014 5:23 am

Posted 16 Jul 2014 5:23 am |

|

I've now grown two more pedals and another lever, so I now have a 4-string E9/B6 universal (the only one in existence??).

I'm happy with how well things work, but not yet with where they are, so I shall spend time making sure I'm comfortable before I add any more strings. To me these four (5-8) are the heart of the machine - there are fewer decisions needed with the others.

https://www.youtube.com/watch?v=hLx7uZjQCYg

_________________

Make sleeping dogs tell the truth!

Homebuilt keyless U12 7x5, Excel keyless U12 8x8, Williams keyless U12 7x8, Telonics rack and 15" cabs |

|

|

|

Ian Rae

From:

Redditch, England

|

Posted 1 Aug 2014 12:08 pm

Posted 1 Aug 2014 12:08 pm |

|

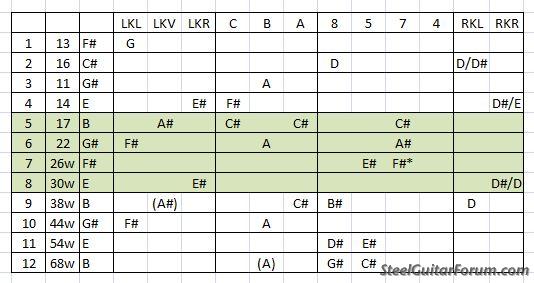

As I mentioned in the last video, I was unhappy with the 8th-string lowers to D# and D on different levers, and I wondered if the following copedent could be made to work (the shaded part):-

It can! Having considered various half-stop ideas for the RKR, I thought I'd have a go at building one straight onto the changer.

As you can see from all the perforations in the little brass trunnion, it took me a few gos to get the geometry right. When the pull hits the stop for D# (centre rod) the mechanical advantage halves (roughly) and is easily felt. The extra push for D is not too heavy. Releasing back to D# is not so obvious, but there is such a thing as practice. Here's a general view of progress. All the shafts are in. I need to fit the LKV then I'll do a video.

There's still quite an assortment of different pullers - they will eventually be replaced with one final design.

_________________

Make sleeping dogs tell the truth!

Homebuilt keyless U12 7x5, Excel keyless U12 8x8, Williams keyless U12 7x8, Telonics rack and 15" cabs |

|

|

|

Ian Rae

From:

Redditch, England

|

Posted 4 Aug 2014 10:35 am

Posted 4 Aug 2014 10:35 am |

|

I've tidied up the tuner.

No sharp edges and the set screws are held much better on axis. Not too pretty close up, but neater. If part of the object of a keyless tuner is to save space, then I've done that. It measures under 2" and I could get it down to 1½" if it mattered enough. Same wrench fits all screws.

_________________

Make sleeping dogs tell the truth!

Homebuilt keyless U12 7x5, Excel keyless U12 8x8, Williams keyless U12 7x8, Telonics rack and 15" cabs |

|

|

|

Alan Brookes

From:

Brummy living in Southern California

|

Posted 4 Aug 2014 10:45 am

Posted 4 Aug 2014 10:45 am |

|

Amazing progress, Ian.  |

|

|

|

Ian Rae

From:

Redditch, England

|

Posted 15 Aug 2014 11:26 am

Posted 15 Aug 2014 11:26 am |

|

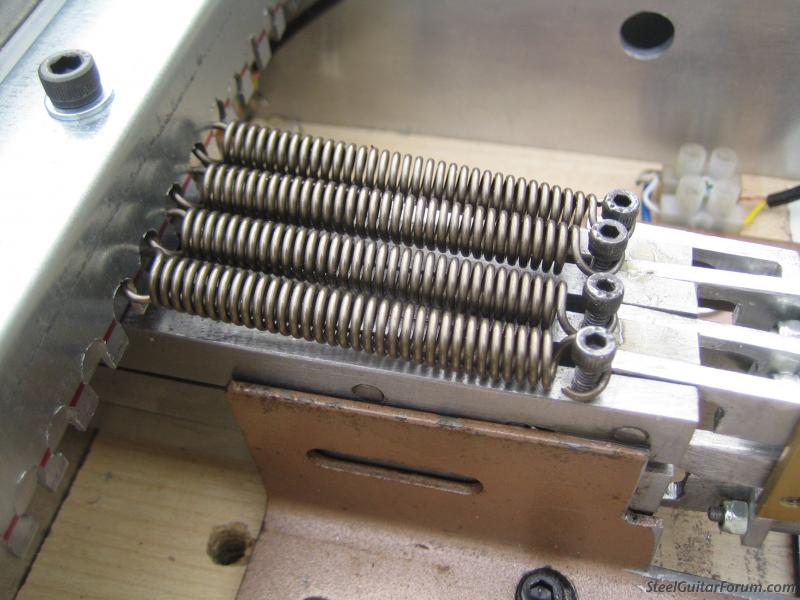

Still only four strings, but I want to get everything right before I carry on.

Amazingly, Redditch is still a centre of spring-making (the needles and fish-hooks for which it was once famous are long gone). I left no room for adjusters for the return springs, so I had to calculate the tension and have some made. There's a small factory a mile away that only requires a minimum order of 50. I seem to have calculated right. The four strings I have include 6th string G# which needs 35lb. for P7 to get it to A#, and it's holding fine without being stiff to lower. That's the tightest string out of the twelve, so the others should be ok.

I have settled on a uniform design for the pull cranks

So what I have now is this and it's working nicely

When I've figured out something to play on it I'll post a video.

_________________

Make sleeping dogs tell the truth!

Homebuilt keyless U12 7x5, Excel keyless U12 8x8, Williams keyless U12 7x8, Telonics rack and 15" cabs |

|

|

|

Ian Rae

From:

Redditch, England

|

Posted 18 Aug 2014 12:08 pm

Posted 18 Aug 2014 12:08 pm |

|

What I did today was swap out the temporary aluminium endplate.

Now it's 1/8" steel and the sustain is further improved, which is no surprise really, but gratifying. (The corner pieces aren't quite right yet  ) )

_________________

Make sleeping dogs tell the truth!

Homebuilt keyless U12 7x5, Excel keyless U12 8x8, Williams keyless U12 7x8, Telonics rack and 15" cabs |

|

|

|

Ian Rae

From:

Redditch, England

|

Posted 4 Sep 2014 1:16 pm

Posted 4 Sep 2014 1:16 pm |

|

I'm going to need a 12-string pickup soon. I can get a George L shipped for around $130 although I don't what model would suit best. One of my design features is a heavy old-fashioned changer which I hope will help give a classic kind of sound, so maybe the EON or E-66. Does anyone have any views on a better choice or things to avoid? I don't want to lay out on anything too fancy at this stage.

The guitar's beginning to look a bit more finished, although I'm still manufacturing parts for the underneath.

The eagle-eyed will spot that the pedal rods don't all look the same. Some are steel and some are aluminium. I can't decide which are better.

_________________

Make sleeping dogs tell the truth!

Homebuilt keyless U12 7x5, Excel keyless U12 8x8, Williams keyless U12 7x8, Telonics rack and 15" cabs |

|

|

|

Ian Rae

From:

Redditch, England

|

Posted 28 Sep 2014 11:46 am

Posted 28 Sep 2014 11:46 am |

|

Since I posted last I've been manufacturing parts. Now I have a complete 12-string changer...

[The thin copper spacers that you might have spotted are there because of the metric mayhem we live in over here (¼" in aluminium is the full 6.3mm but in steel is only 6.0). I couldn't get any washers that thin and the only stuff I had to make some was copper sheet!]

My keyless nutless tuner is really a half-scale model of a pull-release changer without the pulls. I didn't realise it when I sketched it but I can see it now. It has tested well but only time will tell if it breaks 3rd strings. I believe it should be kind. Just waiting for the pickup then I'll string 'er up.

_________________

Make sleeping dogs tell the truth!

Homebuilt keyless U12 7x5, Excel keyless U12 8x8, Williams keyless U12 7x8, Telonics rack and 15" cabs |

|

|

|