Control by Cable-within-Tube

Moderator: Dave Mudgett

-

Jim Palenscar

- Posts: 6021

- Joined: 4 Aug 1998 11:00 pm

- Location: Oceanside, Calif, USA

-

chris ivey

- Posts: 12703

- Joined: 8 Nov 1998 1:01 am

- Location: california (deceased)

-

Will Cowell

- Posts: 388

- Joined: 23 Jan 2008 1:02 pm

- Location: Cambridgeshire, UK

Les Cargill suggested there would be a need for a lot of servos because some guitars have about 30 pulls. That's not really a problem: you have one servo per string. You command the pitch desired shift and the servo responds by changing the string tension until you hit the target note. It doesn't matter how many changes: there will only ever be a need for one servo per string.

My design used miniature motors driving screwjacks. The motors were 18mm diameter, 5 each side, 9.5mm string spacing - no problem. You don't need to program "feel". The "feel" of a conventional PSG derives from the opposition to movement from springs and the string itself - another kind of elastic spring. You can put springs on a servo PSG to simulate the same opposition.

My design used miniature motors driving screwjacks. The motors were 18mm diameter, 5 each side, 9.5mm string spacing - no problem. You don't need to program "feel". The "feel" of a conventional PSG derives from the opposition to movement from springs and the string itself - another kind of elastic spring. You can put springs on a servo PSG to simulate the same opposition.

Williams 700 series keyless U12,

Sierra keyless U14, Eezzee-Slide & BJS bars

Moth-eaten old Marshall 150 combo

Roland Cube 80XL, Peterson Strobo+HD,

EarthQuaker Despatch Master for reverb / delay

Sierra keyless U14, Eezzee-Slide & BJS bars

Moth-eaten old Marshall 150 combo

Roland Cube 80XL, Peterson Strobo+HD,

EarthQuaker Despatch Master for reverb / delay

-

chris ivey

- Posts: 12703

- Joined: 8 Nov 1998 1:01 am

- Location: california (deceased)

-

Jack Aldrich

- Posts: 1004

- Joined: 30 Apr 2010 4:59 pm

- Location: Washington, USA

[quote="Alan Brookes"] I believe the reason that MultiKords were built with all the pedals on the left, in a semicircle, was because of the difficulty of angling the cables from any other place. This could be obviated by the use of bicycle brake cables.

quote]Alan - As I learned the history of the pedal steel from Jeff Newman, Winnie Winston and others, I was told that the impetus behind pedals, at first, was to accomodate retuning and reduce the number of necks on lap steel guitars of the time. Before split pedals, pedal pulls changed whole chrods - e.g., pushing pedal "A" moved the steel from an E to an A tuning. So, until Bud Isaacs recorded "Slowly" with Webb Pierce, nobody moved pedals during a song.

quote]Alan - As I learned the history of the pedal steel from Jeff Newman, Winnie Winston and others, I was told that the impetus behind pedals, at first, was to accomodate retuning and reduce the number of necks on lap steel guitars of the time. Before split pedals, pedal pulls changed whole chrods - e.g., pushing pedal "A" moved the steel from an E to an A tuning. So, until Bud Isaacs recorded "Slowly" with Webb Pierce, nobody moved pedals during a song.

Jack Aldrich

Carter & ShoBud D10's

D8 & T8 Stringmaster

Rickenbacher B6

3 Resonator guitars

Asher Alan Akaka Special SN 6

Canopus D8

Carter & ShoBud D10's

D8 & T8 Stringmaster

Rickenbacher B6

3 Resonator guitars

Asher Alan Akaka Special SN 6

Canopus D8

-

Walter Killam

- Posts: 523

- Joined: 9 May 2006 12:01 am

- Location: Nebraska, USA

-

Les Cargill

- Posts: 774

- Joined: 1 Jan 2014 7:09 pm

- Location: Oklahoma City, Ok, USA

Will Cowell wrote:Les Cargill suggested there would be a need for a lot of servos because some guitars have about 30 pulls. That's not really a problem: you have one servo per string. You command the pitch desired shift and the servo responds by changing the string tension until you hit the target note. It doesn't matter how many changes: there will only ever be a need for one servo per string.

My design used miniature motors driving screwjacks. The motors were 18mm diameter, 5 each side, 9.5mm string spacing - no problem. You don't need to program "feel". The "feel" of a conventional PSG derives from the opposition to movement from springs and the string itself - another kind of elastic spring. You can put springs on a servo PSG to simulate the same opposition.

Yeah, Will - I'm thinking you'd still need a changer, but you've seem to be done gone past me on that detail

Even then my math is off - you'd need at most two servos per string *with* a changer. If there's some way to get a servo to do both lowers and raises that cuts that in half. I bet that's doable, even with the little block ones the guy with the servo Tele bender used.

Your screw jack idea seems better, though.

-

Stephen Williams

- Posts: 257

- Joined: 4 Jun 2013 7:11 pm

- Location: from Wales now in Berkeley,Ca, USA

I'm building a psg with cables.

Re 2 changes per pedal: use 2 cables on the pedal. You can use pulleys etc etc but seems simpler to just use 2 runs from the pedal.

Seems like it would be hard to terminate the cable sheath at the pedal so i was thinking of running bare cable from pedal to deck then using cables ending up in rods.

Re 2 changes per pedal: use 2 cables on the pedal. You can use pulleys etc etc but seems simpler to just use 2 runs from the pedal.

Seems like it would be hard to terminate the cable sheath at the pedal so i was thinking of running bare cable from pedal to deck then using cables ending up in rods.

-

Stephen Williams

- Posts: 257

- Joined: 4 Jun 2013 7:11 pm

- Location: from Wales now in Berkeley,Ca, USA

I'm building a psg with cables.

Re 2 changes per pedal: use 2 cables on the pedal. You can use pulleys etc etc but seems simpler to just use 2 runs from the pedal.

Seems like it would be hard to terminate the cable sheath at the pedal so i was thinking of running bare cable from pedal to deck then using cables ending up in rods.

Re 2 changes per pedal: use 2 cables on the pedal. You can use pulleys etc etc but seems simpler to just use 2 runs from the pedal.

Seems like it would be hard to terminate the cable sheath at the pedal so i was thinking of running bare cable from pedal to deck then using cables ending up in rods.

-

Kevin LaFond

- Posts: 184

- Joined: 21 May 2012 10:21 pm

- Location: Montana, USA

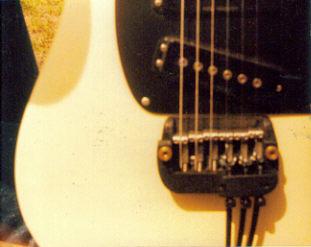

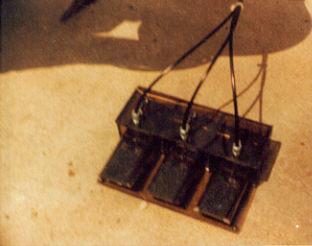

Re: Pedals on a G&L Fender

Dennis, do you still have this guitar?Dennis Brown wrote:I made this in the early 80's. Every thing was made of Lexon except the bike cables and hardware. It worked very well and was pretty quick on the tone return after releasing the pedals. It was a fun project. Dennis

PRP Mullen SD-10, Fender 4x10 Deville, Telecaster and Stratocaster