| Author |

Topic: Question on Hysteresis |

Mark McCornack

From:

California, USA

|

Posted 24 May 2023 3:25 pm

Posted 24 May 2023 3:25 pm |

|

Greetings... I have a question regarding hysteresis as related to string pitch on a pedal steel guitar. Since this is a technical question that PSG designers and builders would encounter, I thought the builders forum would be an appropriate place to ask it.

As I understand it, this is a phenomenon whereby a string which is raised or lowered from a resting state does not return to its original pitch. For example, if the E string (4) is lowered to an Eb then the lever is released, it will "return" to a note slightly sharp of the original E. When raised with an F lever and "returned" it will be slightly on the flat side. This is counter intuitive to me to as the term hysteresis as defined in magnetics (hysteresis loop) has the opposite effect.

Can anyone here explain this phenomenon with regards to the pedal steel and maybe elaborate on what can be done to mitigate it? |

|

|

|

Georg Sørtun

From:

Mandal, Agder, Norway

|

|

|

|

Mark McCornack

From:

California, USA

|

Posted 25 May 2023 8:44 am

Posted 25 May 2023 8:44 am |

|

Georg... Thanks very much for forwarding that information to me. I hadn't given this cause much thought, but kind of assumed it was related to nut roller binding/releasing. The bridge would have never occurred to me as a culprit. The part about Lloyd green abandoning the E to Eb of the 4th string due to hysteresis was quite interesting. Seems like a big sacrifice, but Lloyd did pretty OK without that change  . My guitar is less than 2 cents hysteresis on this particular change, so not too bad. . My guitar is less than 2 cents hysteresis on this particular change, so not too bad.

Over the tears, I've always found your Forum posts very insightful and interesting to read. This was a nice bonus, and thanks again for the reply

Cheers, Mark |

|

|

|

Jim Palenscar

From:

Oceanside, Calif, USA

|

Posted 27 May 2023 8:08 am

Posted 27 May 2023 8:08 am |

|

| I have read Georg's response and wonder why, if it is on the changer end of the guitar, keyless guitars tend to have less hysteresis than keyed guitars? I have read that all metal exhibits this phenomenon and rarely returns to the exact pre-change tension. |

|

|

|

Georg Sørtun

From:

Mandal, Agder, Norway

|

Posted 27 May 2023 8:36 am

Posted 27 May 2023 8:36 am |

|

I have only tested one keyless, and it had all the friction-related hysteresis at the bolt the builder had placed in nut-position. Made a bit worse by my choice of string-set - Jagwire L G Series (with wound 6th), but no slip/hang tendency on the bridge/changer on that particular keyless PSG.

FWIW: although I used a whole set of methods to pinpoint the hysteresis area on each of the PSGs I have tested, anyone can quick-test by applying thick crease on the string(s) and string-contact surface(s) where they think the problem is on their own instrument, and play it. Grease will reduce friction to an absolute minimum … for a minute or two. Should be long enough to check by ear.

Just make sure to get (wash) the grease completely off those strings and surfaces before taking the PSG out for a job, as otherwise chances are that it will be highly unstable/unreliable with regard to hysteresis. |

|

|

|

Jim Palenscar

From:

Oceanside, Calif, USA

|

Posted 27 May 2023 8:56 am

Posted 27 May 2023 8:56 am |

|

| Also I would think that the clearance that both the nut roller as well as the changer scissors and fingers must have in order to function on the axles would also play a role. |

|

|

|

Mark McCornack

From:

California, USA

|

Posted 27 May 2023 10:45 am

Posted 27 May 2023 10:45 am |

|

For my particular guitar (Zumsteel-Encore), the issue is not a showstopper. I am only observing 1.6 to 2.0 cents change on the E(string 4) when raising to F or lowering to Eb and returning. It seems pretty well balanced in that respect.

I also tried cleaning up the nut roller and changer contact area followed by a light application of 3-in-1. Neither of these made a measurable difference in the hysteresis. Again, it's fortunately a minor issue on this guitar.

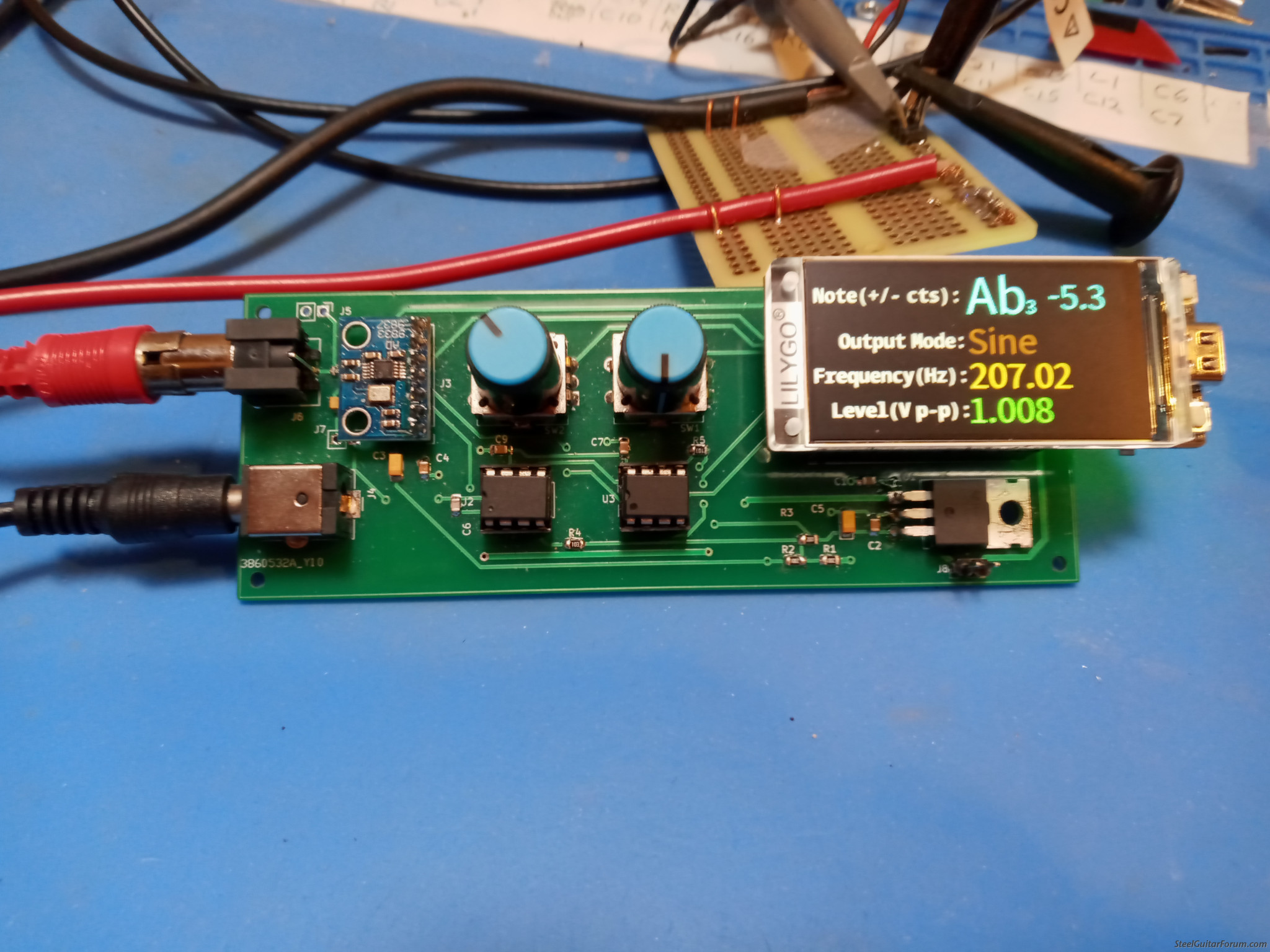

The measurements getting into the tenths of cents is really overkill in terms of picking the fly-s**t out of the pepper, but I have a good stable means of making these measurements. I made a signal generator that allows me to dial in a note, octave, and offset from ET (in tenths of cents with firmware as shown). The signal generator triggers an oscilloscope that has the steel's pickup output tied to a viewed channel. It's very easy then to dial in a "zero beat" observation on the scope. Just monitor the change required in the signal generator (i.e the scope trigger source) to freeze the output phase of the steel.

Tenths-of-cents has little merit in terms of useful human perception of musical pitch, but I think there is still some academic merit in seeing what incremental design changes hold (if any) "quantifiable" pitch change.

|

|

|

|

Georg Sørtun

From:

Mandal, Agder, Norway

|

Posted 27 May 2023 11:50 am

Posted 27 May 2023 11:50 am |

|

| Mark McCornack wrote: |

| Tenths-of-cents has little merit in terms of useful human perception of musical pitch, but I think there is still some academic merit in seeing what incremental design changes hold (if any) "quantifiable" pitch change. |

A "slight" overkill, yes  . But can be good if one feels like documenting tuning-deviations for an instrument under stress. I use to rely on a frequency counter for that; with 4 digits after comma in the relevant range. Total overkill, but does not hurt and I do not have to write them all down. . But can be good if one feels like documenting tuning-deviations for an instrument under stress. I use to rely on a frequency counter for that; with 4 digits after comma in the relevant range. Total overkill, but does not hurt and I do not have to write them all down.

I am generally more interested in seeing how parts of a PSG move – absolutely and relative to other parts, with varying tension. For that I have used tiny mirrors fixed with putty or glue, and a fixed light-source, in effect creating a set of amplifying light-meters. The reflections definitely "dance" more on some PSGs than on others when pedals/levers are pushed. |

|

|

|

Allen Merrell

From:

Georgia, USA

|

Posted 27 May 2023 12:08 pm

Posted 27 May 2023 12:08 pm |

|

I have an Encore that is the same on E lower but on raising the E to F it is dead on. I had this same issue with my Bud but was able to correct it by a very slight adjustment on the return spring. It took a little playing around with the spring but I was able to get it dead on. I messaged Doug E about the Encore and he said it sounded like it needed lubeing but I gave it a try and it had very little effect. The return springs on my Encore are non adjustable. I am considering making springs and plate that would allow me to adjust this return. This is an interesting discussion can't wait to see what the fix is. Georg, thanks for your article.

_________________

72 ShoBud 6153 D10, Encore, Nashville 112, Boss Katana, Spark 40, Quilter TT12, GT001, ProFex II,Jackson Pitch changer (Love this bender) |

|

|

|

J D Sauser

From:

Wellington, Florida

|

Posted 13 Jun 2023 6:15 am

Posted 13 Jun 2023 6:15 am |

|

I don’t know who came up with the term Hysterisis, but I’ve always suspected it could be not entirely accurate to describe this phenomenon.

It’s NOT brand dependent, but evidently guitars with easy rollng nut rollers will have less of that “neutral”-detuning on strings which are both raised AND lowered.

Keyless guitars will display the least of this bottersome phenomenon, so will guitars with shorter key heads and thus also strings which are closer to the outer ends of a key head, as as string lengths are shorter the extent of the phenomenon also diminishes.

Perception: Most of us will not hear or be bottered by a 2 or 3 cent PITCH inacuracy… UNLESS there is a reference.

There’s a lot if that and worse going on as we play and use changes.

But there are pure intervals like octaves, fourths and fifths which will have some noticeable wobble with one or the other string acting capriciously.

… JD

_________________

__________________________________________________________

Was it JFK who said: Ask Not What TAB Can Do For You - Rather Ask Yourself "What Would B.B. King Do?"

A Little Mental Health Warning:

Tablature KILLS SKILLS.

The uses of Tablature is addictive and has been linked to reduced musical fertility.

Those who produce Tablature did never use it.

I say it humorously, but I mean it. |

|

|

|

Jacobus De Bruyn

From:

NSW, Australia

|

Posted 24 Jun 2023 3:32 pm

Posted 24 Jun 2023 3:32 pm |

|

| To understand. Is this issue only on string 4 E string. The reason I ask. I am the Electro Steel Builder in this forum, and I tried to figure out why my E string does not return to E but all other strings return 100% to its coded positions. |

|

|

|

Steve Mueller

From:

Cincinnati, Ohio, USA

|

Posted 24 Jun 2023 7:21 pm

Posted 24 Jun 2023 7:21 pm |

|

Pitch return comps solve the problem. I have them on all strings with a raise and a lower on my Williams guitars. It becomes a non-issue. I know PF has them on his guitars. I don't know why all pedal steels aren't made with them. This is an issue which affects nearly all guitars.

I think 2-3 cents matters, especially when combined with other changes as you play.

_________________

2016 Williams D12 8 x 8, 2015 Williams D12 8 x 8, 2023 Williams S12 4 x 5, Milkman Amps, 1974 Gibson Byrdland |

|

|

|

Jacobus De Bruyn

From:

NSW, Australia

|

Posted 25 Jun 2023 3:29 am

Posted 25 Jun 2023 3:29 am |

|

| Can you sent me a picture or photo to see what it is and looks like please. |

|

|

|

Steve Mueller

From:

Cincinnati, Ohio, USA

|

Posted 25 Jun 2023 6:39 am

Posted 25 Jun 2023 6:39 am |

|

OK. Give me a day or two.

_________________

2016 Williams D12 8 x 8, 2015 Williams D12 8 x 8, 2023 Williams S12 4 x 5, Milkman Amps, 1974 Gibson Byrdland |

|

|

|

J D Sauser

From:

Wellington, Florida

|

Posted 30 Jun 2023 1:00 am

Posted 30 Jun 2023 1:00 am |

|

VERY interesting analysis and conclusions!

I’d be interesting to compare KEYED guitars with less “string pressure” at the canger (like Williams with the shallow chnger finger tail) to a guitar with a wrap-around strind design and also compare (lets for the argument’s sake) a keyed and a key less Williams to see if the left end does or not affect too.

I once built a “Left-Change’n’Tune” PSG. The strings’ ball end was loged at the changer en in the tuning device, while the open end was locked with a screw right behind the bridge’s edge. We had no more noticeable “String Hysterisis” but attributet it to the left changer design wich incorporated rollers the size of a normal pull-finger’s radius which ran freely and seemed less prone to be “sticky”.

… JD.

… JD

_________________

__________________________________________________________

Was it JFK who said: Ask Not What TAB Can Do For You - Rather Ask Yourself "What Would B.B. King Do?"

A Little Mental Health Warning:

Tablature KILLS SKILLS.

The uses of Tablature is addictive and has been linked to reduced musical fertility.

Those who produce Tablature did never use it.

I say it humorously, but I mean it. |

|

|

|

Jim Palenscar

From:

Oceanside, Calif, USA

|

Posted 8 Jul 2023 7:42 am

Posted 8 Jul 2023 7:42 am |

|

| It has been my experience that the roller axle size also plays a role here w the smaller axles having less friction due to the more limited contact area w the rollers themselves. |

|

|

|

Mark McCornack

From:

California, USA

|

Posted 10 Jul 2023 4:10 pm

Posted 10 Jul 2023 4:10 pm |

|

| Interesting, Jim. With all the many guitars that have been in your purview over the years, have you seen any significant design differences in roller nut diameters? If so, does that have an influence on stiction as well? |

|

|

|

Jim Palenscar

From:

Oceanside, Calif, USA

|

Posted 10 Jul 2023 6:31 pm

Posted 10 Jul 2023 6:31 pm |

|

| Not sure Mark. |

|

|

|

memphislim

From:

Austin, Texas

|

Posted 13 Jul 2023 10:33 am

Posted 13 Jul 2023 10:33 am |

|

I've got one of Paul Redmond's keyless Whitney guitars and the roller nuts are huge and the axle tiny. No hysteresis at all. This guitar has a dual changer design whereby the lowers happen on the opposite side as the raises. This may be contributing to "no hysteresis" . I do notice that the bigger the roller nuts, ie my Mullen PRP's, the less hysteresis.

|

|

|

|

Mark McCornack

From:

California, USA

|

Posted 13 Jul 2023 3:07 pm

Posted 13 Jul 2023 3:07 pm |

|

| Those do look big! In addition, on this guitar with the keyless head, you have less string length on the "dead" side of the nut than a traditional keyed head. A differential string tension on either side of the nut would translate to less displacement at the nut itself (if I understand this phenomenon correctly). |

|

|

|

John Hyland

From:

South Australia

|

Posted 14 Jul 2023 1:25 pm

Posted 14 Jul 2023 1:25 pm |

|

Rambling Thoughts only:

Regardless of the size of the nut rollers the string needs to stretch the same amount during a change. So on my logic a larger roller will roller much more easily than a small one. Does that mean it is a no brained to have large diameter rollers.?

Also It also stands to reason that less string on the negative side of the nut will have less opportunity to hold the change in tension after release of a note change. If a string length changes at the finger, at its fixed point the movement is zero. Therefore the movement at the nut would be proportionally less as a factor of the total string length. Hence the movement at the nut is very small. Is it enough to create hysteresis? |

|

|

|

Mark McCornack

From:

California, USA

|

Posted 14 Jul 2023 2:58 pm

Posted 14 Jul 2023 2:58 pm |

|

@John Hyland....Thank you for stating clearly and concisely the thought I stumbled over trying to get out! You expressed what I intended to with far less "Rambling"....  |

|

|

|

Georg Sørtun

From:

Mandal, Agder, Norway

|

Posted 14 Jul 2023 6:50 pm

Posted 14 Jul 2023 6:50 pm |

|

To see what hysteresis on the changer may look like when drawn, I'll present the following sketch…

I have seriously overdone the amount of rotation needed for raise and lower to make it easier to draw, but otherwise it is as I have measured on my own PSGs. It may look as I have drawn the slip/hang hysteresis effect backwards, but focus on the string and it should not matter.

When it comes to hysteresis on the nut-rollers: tight-fitting rollers on the axle combined with dried-out oil on that axle, can cause the same hysteresis-effect there. I used to have a spray-can with super-thin oil to remedy that problem when it happened "on the job".

Polishing down the axle to achieve a not-quite-so-tight fit, remedied it permanently at that end on my main PSG. No rattling sounds after such a "fix" there. |

|

|

|

J D Sauser

From:

Wellington, Florida

|

Posted 15 Jul 2023 12:26 am

Posted 15 Jul 2023 12:26 am |

|

| Georg Sørtun wrote: |

To see what hysteresis on the changer may look like when drawn, I'll present the following sketch…

I have seriously overdone the amount of rotation needed for raise and lower to make it easier to draw, but otherwise it is as I have measured on my own PSGs. It may look as I have drawn the slip/hang hysteresis effect backwards, but focus on the string and it should not matter.

When it comes to hysteresis on the nut-rollers: tight-fitting rollers on the axle combined with dried-out oil on that axle, can cause the same hysteresis-effect there. I used to have a spray-can with super-thin oil to remedy that problem when it happened "on the job".

Polishing down the axle to achieve a not-quite-so-tight fit, remedied it permanently at that end on my main PSG. No rattling sounds after such a "fix" there. |

This is one of the most interesting conclusions or theories I have ever seen on this issue, Georg.

When we built our first left-change prototype, we used a lefty MSA we turned the neck and pickup around and fitted with a "clean bridge, and used all it's hardware, except for the changer fingers which were re-designed to incorporate tuning. Because tuning now was ON the changer finger, right behind it's traditional big radius, we chose to slice the finger and incorporate a v-grooved roller of the same radius as a typical changer finger. We had ZERO "hysteresis", which we attributed to the presence of a "keyless" tuning with minimal string length and the clean bridge (while changing was occurring on the left.

YOUR analysis could suggest that while all our mods may indeed contribute to less of that undesirable effect, the existence of a roller with with sting at a shallow angle (like on a Williams or new Sierra, meaning that the strings lay on less surface than on a typical changer finger with the string wrapped around on it 90deg. could in fact have been the foremost contributor to fixing that problem!

Interesting!

Evidently, a sliced in roller could be integrated in most traditional changer fingers, all-and-push-pull.

"We" should try that. Additionally, a changer integrated roller, allows for v-grooving which enhances lateral string support and would better tonal dynamics and sustain (instead of the string moving on a surface (seen as a little "V" fan indent on the changer fingers over time).

Thanks!... J-D.

_________________

__________________________________________________________

Was it JFK who said: Ask Not What TAB Can Do For You - Rather Ask Yourself "What Would B.B. King Do?"

A Little Mental Health Warning:

Tablature KILLS SKILLS.

The uses of Tablature is addictive and has been linked to reduced musical fertility.

Those who produce Tablature did never use it.

I say it humorously, but I mean it. |

|

|

|

Jim Pitman

From:

Waterbury Ctr. VT 05677 USA

|

Posted 21 Jul 2023 8:16 am

Posted 21 Jul 2023 8:16 am |

|

| My Infinity has little to no hysteresis. The only physically obvious difference with other guitars I've owned is, the diameter of the axle at the nut. It's a mere 0.063". The changer also has bearings where the scissors meets the fingers. |

|

|

|