| Author |

Topic: Binding on pull/release |

Tim Toberer

From:

Nebraska, USA

|

Posted 8 Feb 2023 3:43 pm

Posted 8 Feb 2023 3:43 pm |

|

My pull/release guitar is coming together. I was able to get it almost in tune today, but the action is not going so smooth, so it is back up on the bench.

I was able to relieve some of the binding in number of spots, but the worst is on the fingers with lower and raise where, on the raises the finger is grinding on the threaded part of the lower rod going through the same finger.

Is there a small teflon sleeve or something I could use over the threads that would still allow tuning?

Or maybe ream out the changer finger holes (which is happening anyways as the threads grind on the finger)? Graphite or silicone?? I don know I am at a loss. It does work, but not smoothly. |

|

|

|

Bill Johnson

From:

Washington, USA

|

Posted 8 Feb 2023 4:45 pm

Posted 8 Feb 2023 4:45 pm |

|

Tim,

I am no expert on pull release changers, but none of the ones I have examined

have the threads of the rods going through the fingers.

The rods I have seen only have a small amount of thread on them where you install

a nut and a spacer sleeve to the outward side of the fingers thus eliminating the threads grinding in the holes.

Just like an all pull changer, you don't want the threads extending into the fingers for the reasons you have mentioned.

If there is enough clearance in the finger holes and rod size, maybe some shrink tubing could be a temporary fix?

Just my thoughts, good luck on your project. |

|

|

|

Tim Toberer

From:

Nebraska, USA

|

Posted 9 Feb 2023 7:18 am

Posted 9 Feb 2023 7:18 am |

|

| Bill Johnson wrote: |

Tim,

I am no expert on pull release changers, but none of the ones I have examined

have the threads of the rods going through the fingers.

The rods I have seen only have a small amount of thread on them where you install

a nut and a spacer sleeve to the outward side of the fingers thus eliminating the threads grinding in the holes.

Just like an all pull changer, you don't want the threads extending into the fingers for the reasons you have mentioned.

If there is enough clearance in the finger holes and rod size, maybe some shrink tubing could be a temporary fix?

Just my thoughts, good luck on your project. |

Time to remake all my lower rods LOL. I see now, having never seen in person a pull/ release guitar I am working from photos and whatever info I can find on the web. The next guitar will be easy! Thanks I knew something wasn't right. |

|

|

|

Bobby D. Jones

From:

West Virginia, USA

|

Posted 9 Feb 2023 7:49 pm

Posted 9 Feb 2023 7:49 pm |

|

Yes you will need a sleeve to cover the threads, So that only smooth rod runs through the changer fingers.

Take the longest rods and shorten them to the next set of rods, Work down through all the pulls. That way you will only need new long rods for far left pedal .

On the old MSA Classic guitars the spacer/sleeve was made out of 1/4" aluminum rod with a hole drilled through the center.

Good Luck in this modification. |

|

|

|

Bill Johnson

From:

Washington, USA

|

Posted 9 Feb 2023 9:41 pm

Posted 9 Feb 2023 9:41 pm |

|

What Bobby says is correct.

What I use on my MSA's is the 1/4" O.D. X .180 I.D. all purpose aluminum tube, available from McMaster-Carr.

It is a perfect fit, and it cuts easily and cleanly with a tubing cutter.

I taper the finger end of the sleeve slightly (somewhat like a pencil) and polish smooth, so it won't catch on the fingers next to it.

McMaster-Carr also has pre-cut spacers in metal and plastic which work quite well. (Depending on rod size, a little fitting might be needed) |

|

|

|

Tim Toberer

From:

Nebraska, USA

|

Posted 10 Feb 2023 6:05 am

Posted 10 Feb 2023 6:05 am |

|

I found some nylon spacers at the hardware store that seem like they should could work but have a fairly thin wall. They are 3/16 with 1/8 id. I have some 1/4 brass that I could drill out which might be better. The rods are 3/32.

I have a non standard tuning, more based around A6, but I was able to play it a little with the lowers working and It was pretty exciting. No knee levers 8 pedals, so pretty ambitious for a first project. I thought wow this thing might actually work! Thanks for the tips hopefully that was my last big trip on this thing. |

|

|

|

Bill Johnson

From:

Washington, USA

|

Posted 10 Feb 2023 9:11 am

Posted 10 Feb 2023 9:11 am |

|

The 1/4" brass would be a great choice. You can get a perfect fit for your rods.

In the end, there is nothing like the satisfaction you get when you overcome an obstacle on a project.

Good luck to you, we have all been there. |

|

|

|

Tim Toberer

From:

Nebraska, USA

|

Posted 13 Feb 2023 6:39 am

Posted 13 Feb 2023 6:39 am |

|

| I got some 1/4" aluminum that worked well and looks better. Hopefully get this thing up and running sometime this week. |

|

|

|

Bobby D. Jones

From:

West Virginia, USA

|

Posted 20 Feb 2023 8:54 pm

Posted 20 Feb 2023 8:54 pm |

|

Do you have spacers between each finger on the changer.

Back in about 1970, Several guys in my town were trying to build steel guitars. The first few had no spacers between the changer fingers and had problems. When I drew up plans for mine, I put spacers between the finger. I cut a set out of brass shim stock about .020 thick, Had no problem with my changer. The pull rod holes, In a pull and release changer have to be wobbled out in line with length only, So the fingers can move without binding on the pull rods. No threads on the pull rod where it goes through the finger helps too. Good Luck in solving the problem. |

|

|

|

Tim Toberer

From:

Nebraska, USA

|

Posted 22 Feb 2023 7:25 am

Posted 22 Feb 2023 7:25 am |

|

| Bobby D. Jones wrote: |

Do you have spacers between each finger on the changer.

Back in about 1970, Several guys in my town were trying to build steel guitars. The first few had no spacers between the changer fingers and had problems. When I drew up plans for mine, I put spacers between the finger. I cut a set out of brass shim stock about .020 thick, Had no problem with my changer. The pull rod holes, In a pull and release changer have to be wobbled out in line with length only, So the fingers can move without binding on the pull rods. No threads on the pull rod where it goes through the finger helps too. Good Luck in solving the problem. |

I am still having some issues with binding and I am thinking that this is one of the issues. There isn't any room to fit spacers unless I maybe sanded down the fingers or something. I have another changer I made out of 1/4 thick stock that should work. I may do this when I change strings. The main issue I am having is the pedals will not return to exactly the same spot every time which makes it difficult to tune and play obviously. The lowers are more problematic. I think something that may help is heavier strings. The scale length is short at 22 1/2" so it doesn't take much spring tension to counteract the strings. When I build another one I will go with a longer scale length. I added some temporary pedal return springs made out of rubber bands which makes it more playable, but the pedals are always up which makes for a long throw. I prefer it without the return springs.

There is also some bending and binding on the rods and bell cranks which are a bit rough. I think with a butterfly design bell crank, like a Marlen, and 1/8" rods, this would work much better. It is playable so I am just enjoying making some music for now cause I need a break from working on this thing  |

|

|

|

Barry Coker

From:

Bagley Alabama, USA

|

Posted 22 Feb 2023 3:05 pm

Posted 22 Feb 2023 3:05 pm |

|

A big thing to remember on Pull/Release the strings that raises and lowers need space or clearance if you lower E's to Eb your F lever needs clearance it will move backwards so E lever F lever and C pedal watch your linkage and leave clearance.

Good Luck

Barry

_________________

Zum-D-10, Webb 614-E, 65 Pro Reverb, Evans RE200, 69 Gibson Birdland, 89 Telecaster EAD Bad!! |

|

|

|

Tim Toberer

From:

Nebraska, USA

|

Posted 23 Feb 2023 3:09 pm

Posted 23 Feb 2023 3:09 pm |

|

| Bobby D. Jones wrote: |

Do you have spacers between each finger on the changer.

Back in about 1970, Several guys in my town were trying to build steel guitars. The first few had no spacers between the changer fingers and had problems. When I drew up plans for mine, I put spacers between the finger. I cut a set out of brass shim stock about .020 thick, Had no problem with my changer. The pull rod holes, In a pull and release changer have to be wobbled out in line with length only, So the fingers can move without binding on the pull rods. No threads on the pull rod where it goes through the finger helps too. Good Luck in solving the problem. |

How do you cut these washers? |

|

|

|

Bill Johnson

From:

Washington, USA

|

|

|

|

Bobby D. Jones

From:

West Virginia, USA

|

Posted 23 Feb 2023 8:22 pm

Posted 23 Feb 2023 8:22 pm |

|

Tim, I done the spacers sort of crude. I drilled the holes in the shim stock, Cut them out close with tin snips. Then stacked them on a short bolt, Chucked the bolt in a drill, Clamped to my workbench. With a file rounded and sized them.

Very primitive but it worked. |

|

|

|

Tim Toberer

From:

Nebraska, USA

|

Posted 25 Feb 2023 10:16 am

Posted 25 Feb 2023 10:16 am |

|

| Bobby D. Jones wrote: |

| Tim, I done the spacers sort of crude. |

As long as it works! My guitar will never win a beauty contest, I just want her to start singing in tune. I have a punch I may try using.

I just found this thread which solved another problem I am having in tuning the open notes. The stop collar needs slot into the bell crank. I have been having to hold the springs when I tune the open notes. Great view of the Marlen bell cranks!

https://bb.steelguitarforum.com/viewtopic.php?t=326023&sid=1d11d3e212dfe2f55d90c59b01404004 |

|

|

|

Brett Lanier

From:

Madison, TN

|

Posted 14 Apr 2023 9:22 am

Posted 14 Apr 2023 9:22 am |

|

There sure is a lot of problem solving that goes into setting up a pull release! I just pulled my Marlen D10 apart earlier this week, cleaned it and put it back together.

One thing that could be a problem is the angle of the finger as it swings towards the body, or back to the set screw - with an improper design, as the finger angle changes, the hole in the changer can become too narrow for the rod and it will get pinched. Do all you can to avoid having threads get near the fingers, but binding will still happen if the rod/finger hole angle isn't right.

I've never had an issue with not having spacers between the fingers on older guitars. I have a '66 Marlen that has em and an older one that doesn't. Both play great and I wouldn't ever consider adding them to the older guitar. I think with the old designs that consist of just an axle with plain fingers it's necessary to take the changers out every couple years, remove the dirt and oil, re-oil lightly and put back together.

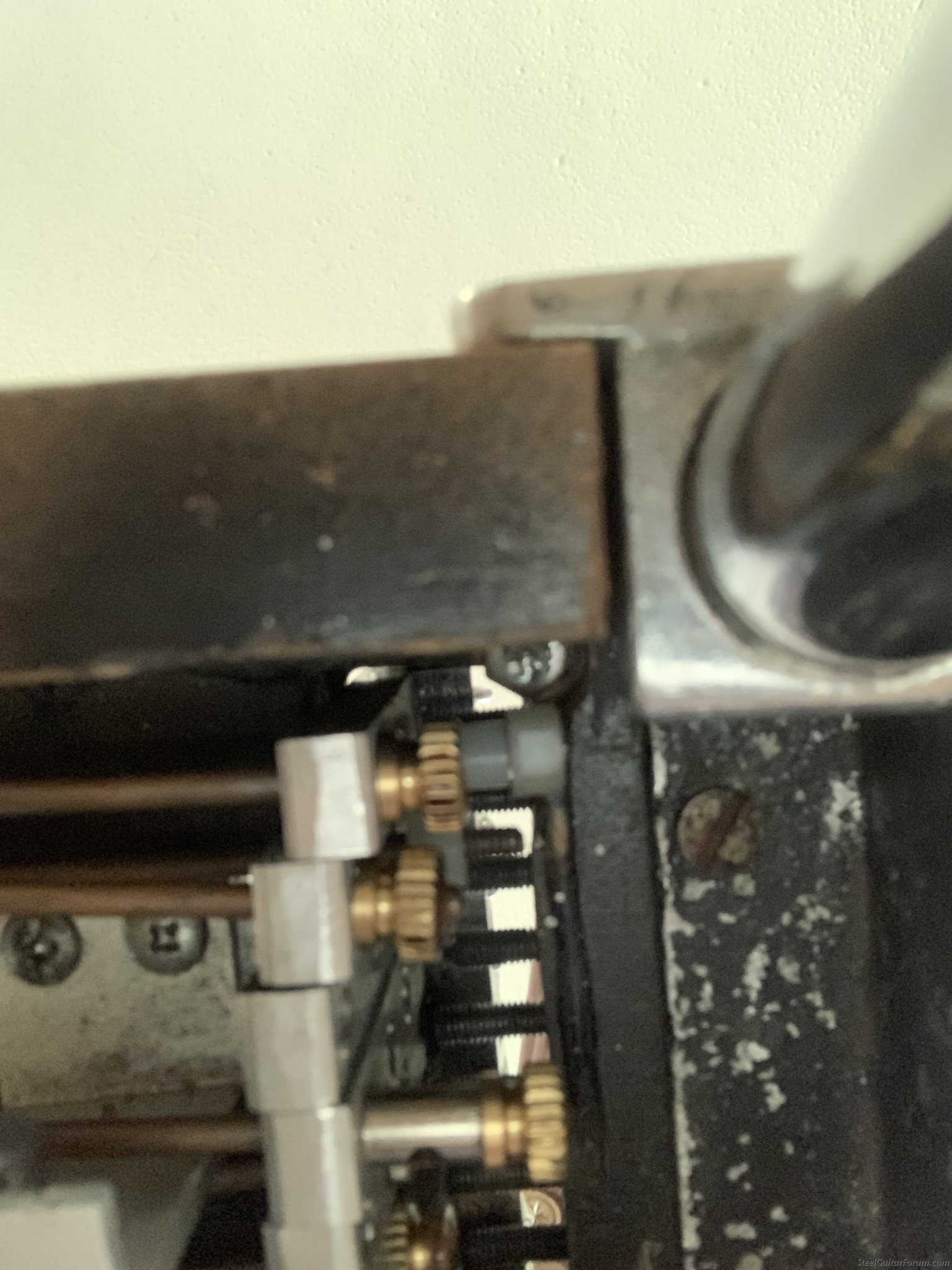

Most Ace hardware stores have these little round knurled brass things that thread onto an 1/8" rod. I've got a whole bunch of them on my guitar in various spots for tuning. They are quite handy. I also like using the nylon nuts they have which you can also kinda see in this picture.

|

|

|

|

Andy DePaule

From:

Saigon, Viet Nam & Springfield, Oregon

|

Posted 14 Apr 2023 3:46 pm Simple solution maybe?

Posted 14 Apr 2023 3:46 pm Simple solution maybe? |

|

If I were thinking of building a pull release...

Simple solution maybe would be to have all the raising strings pull on the normal changer end. I would also have the strings that lower work on the changer with a push to lower held in the high note against the body with a spring.

Then I'd use one of several ways I'v seen or just thought of to lower the raise and lower strings (Usually just the e's) done in the peghead?

Consider something like some of the Jackson guitars used where the tuning machine on those strings was allowed to pivot to lower and then return via spring.

Another option I think would work very well would be to have a cam that the string rides on between the tuning machine post and the nut. I don't think it would require a very strong spring to return a cam to the raised position?

I have never seen this, but if I was going to build one I'd experiment with that first.

For the double raise like the E to F lever and E to F# pedal, just have the finger pulled by two rods and tune the E to F under the steel.

Well that's my 2¢ and well worth what I charged your account!

_________________

Inlaid Star Guitar 2006 by Mark Giles. SD-10 4+5 in E9th; http://luthiersupply.com/instrument-gallery.html

2017 Mullen SD-10, G2 5&5 Polished Aluminum covering. Custom Build for me. Great Steel.

Clinesmith Joaquin Murphy style Aluminum 8 String Lap Steel Short A6th.

Magnatone Jeweltone Series Lap Steel, Circa 1950? 6 String with F#minor7th Tuning.

1956 Dewey Kendrick D-8 4&3, Restoration Project.

1973 Sho~Bud Green SD-10 4&5 PSG, Restoration Project. |

|

|

|

Tim Toberer

From:

Nebraska, USA

|

Posted 15 Apr 2023 5:20 am

Posted 15 Apr 2023 5:20 am |

|

Thanks for the insight. I definitely underestimated how little friction can cause a problem. I doused everything in oil and it didn't really help. I think when I drilled the axle holes in the changer a few are not perfectly parallel. Raising and lowering every string makes a lot of options for things to not always line up. I still play it, but it is a devil to tune and every time I raise the e it returns sharp. I have gotten in the habit of tapping the lower pedal to return it. At least it allows me to explore the tuning.

I plan on installing a new changer when I finish my next guitar. I have a new design that is made from 1/4" aluminum and has thick spacers in between. Hopefully that will solve the problem. I also redesigned the bell cranks so the rods can have straight runs to the changer. |

|

|

|

Brett Lanier

From:

Madison, TN

|

Posted 15 Apr 2023 8:38 am

Posted 15 Apr 2023 8:38 am |

|

| Do you have any pictures? |

|

|

|

Tim Toberer

From:

Nebraska, USA

|

|

|

|