Repair Fender Volume-Tone pedal - string tension?

Moderator: Dave Mudgett

-

Roman Sonnleitner

- Posts: 759

- Joined: 27 Nov 2005 1:01 am

- Location: Vienna, Austria

Repair Fender Volume-Tone pedal - string tension?

Guys, are there any tricks for restringing one of those old Fender Volume-Tone pedals?

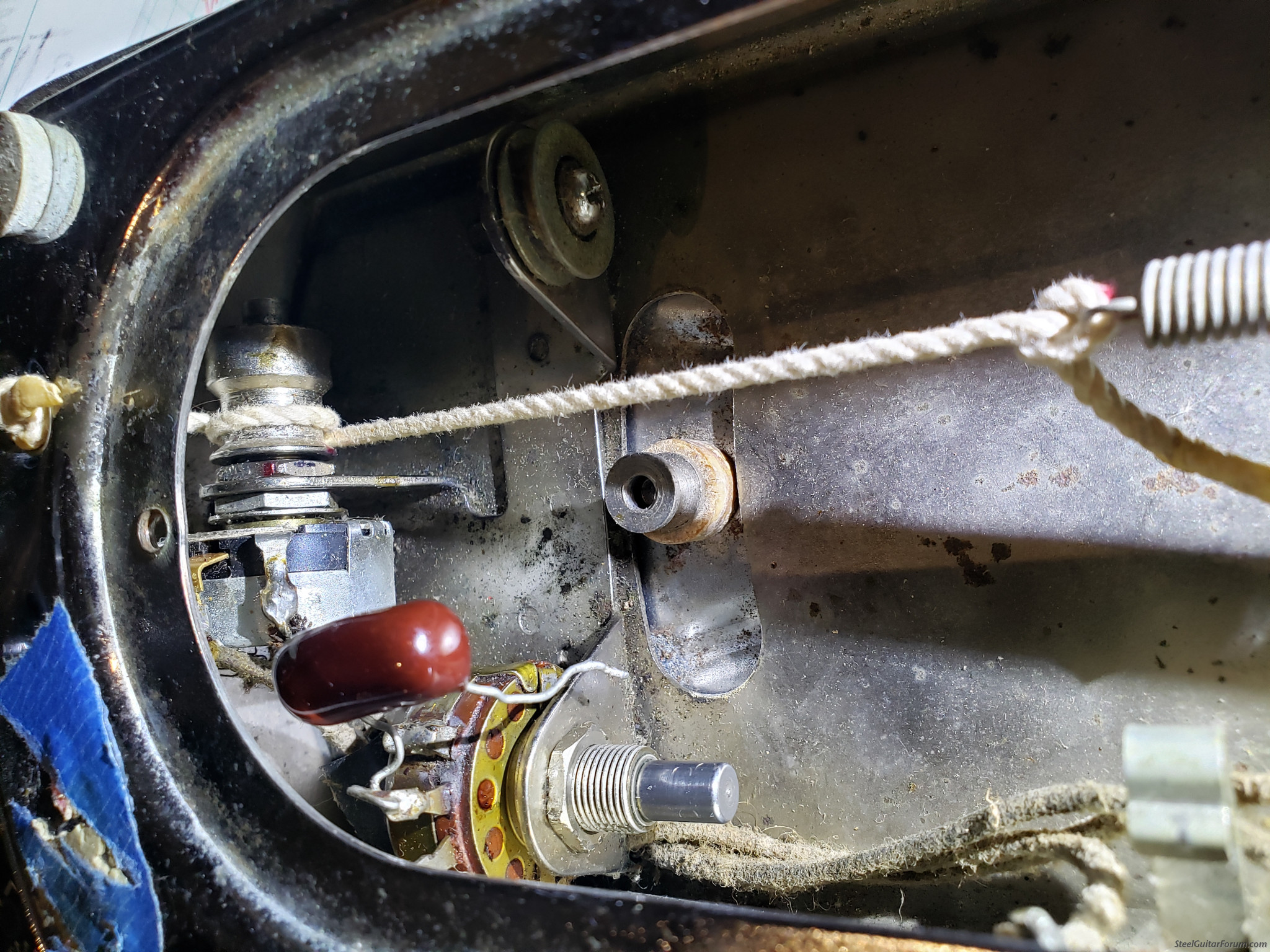

I recently had to change the volume pot on mine, because the old one had gotten very scratchy (even deoxit spray didn't help), and ever since it hasn't been working correctly - either the string slips around the axle of the pot, and the pot stays turned off after a few times of working the treadle, or if I tighten/shorten it, the pedal automatically reverts to the fully on position, doesn't stay where I want it, so I can't take my foot off of it...

Am I doing something wrong? Is there a trick for getting the string length and tension right? I don't assume there is a manual for doing that (mine is an old version, not the re-issue from a few years ago)?

I recently had to change the volume pot on mine, because the old one had gotten very scratchy (even deoxit spray didn't help), and ever since it hasn't been working correctly - either the string slips around the axle of the pot, and the pot stays turned off after a few times of working the treadle, or if I tighten/shorten it, the pedal automatically reverts to the fully on position, doesn't stay where I want it, so I can't take my foot off of it...

Am I doing something wrong? Is there a trick for getting the string length and tension right? I don't assume there is a manual for doing that (mine is an old version, not the re-issue from a few years ago)?

-

Tim Whitlock

- Posts: 2020

- Joined: 3 Jan 2001 1:01 am

- Location: Colorado, USA

Getting these pedals set up right is very tricky. Here are a few things I have leaned - most of them pretty obvious but hopefully might help:

You have to use the right string that will have some "grab" to it, or your volume pot will slip as you described. I use landscaping line from the hardware store. I also tried to rough up the spindle with a file to give the string something to grab onto. I have thought about coating the string with something sticky but never got around to trying it. You do want to use a pot that turns smoothly with little resistance.

Of course you have the thread the string correctly through the pulley in the back of the pedal so it will stay in the off position when you take your foot off. With the pedal on its back, the string should run from the top pulley and enter at the bottom of the spindle.

Here is how I connect the two pieces of string to the spring. Visualize this with the pedal upside down and in the full on position. I find it's easier to tie the back string to the spring and then get it threaded through the pulleys in the back. Then I wind the front string around the spindle and then bring it through the loop of the spring. This way you can vary the tightness of the spring before you tie it off. The alternative is to tie the front string to the spring and then try to wrap it around the spindle - this can be extremely frustrating.

Lastly - you don't want to get the string too tight or the pedal action will be sticky. Anyway - hope this helps. Question for you - what kind of pot did you use to replace the old one?

You have to use the right string that will have some "grab" to it, or your volume pot will slip as you described. I use landscaping line from the hardware store. I also tried to rough up the spindle with a file to give the string something to grab onto. I have thought about coating the string with something sticky but never got around to trying it. You do want to use a pot that turns smoothly with little resistance.

Of course you have the thread the string correctly through the pulley in the back of the pedal so it will stay in the off position when you take your foot off. With the pedal on its back, the string should run from the top pulley and enter at the bottom of the spindle.

Here is how I connect the two pieces of string to the spring. Visualize this with the pedal upside down and in the full on position. I find it's easier to tie the back string to the spring and then get it threaded through the pulleys in the back. Then I wind the front string around the spindle and then bring it through the loop of the spring. This way you can vary the tightness of the spring before you tie it off. The alternative is to tie the front string to the spring and then try to wrap it around the spindle - this can be extremely frustrating.

Lastly - you don't want to get the string too tight or the pedal action will be sticky. Anyway - hope this helps. Question for you - what kind of pot did you use to replace the old one?

-

Roman Sonnleitner

- Posts: 759

- Joined: 27 Nov 2005 1:01 am

- Location: Vienna, Austria

-

Tim Whitlock

- Posts: 2020

- Joined: 3 Jan 2001 1:01 am

- Location: Colorado, USA

-

Steve Spitz

- Posts: 2156

- Joined: 11 Jul 2001 12:01 am

- Location: New Orleans, LA, USA

-

Ken Fox

- Posts: 9724

- Joined: 20 Apr 2001 12:01 am

- Location: Nashville GA USA

-

Patrick Timmins

- Posts: 197

- Joined: 19 Jul 2019 1:32 pm

- Location: Seattle

Apologies for resurrecting this old thread. I followed the link above from Ken and the images are no longer there.

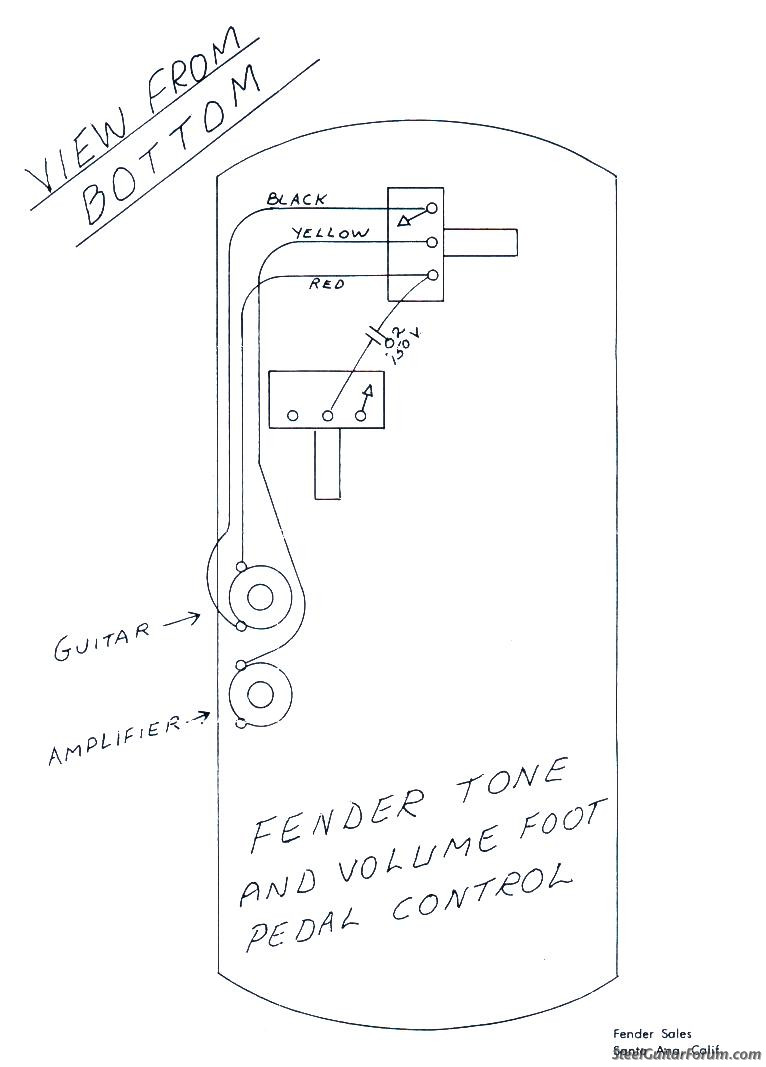

I just picked up an old Fender Volume/tone pedal and someone removed the tone pot from the circuit (left the pot). The pulley that goes over the tone pot post is missing as well as the string and spring. Everything else seems to be there.

Is the pulley that goes over the volume and tone pot posts the same size? I may need to fabricate one but don't know what size it needs to be.

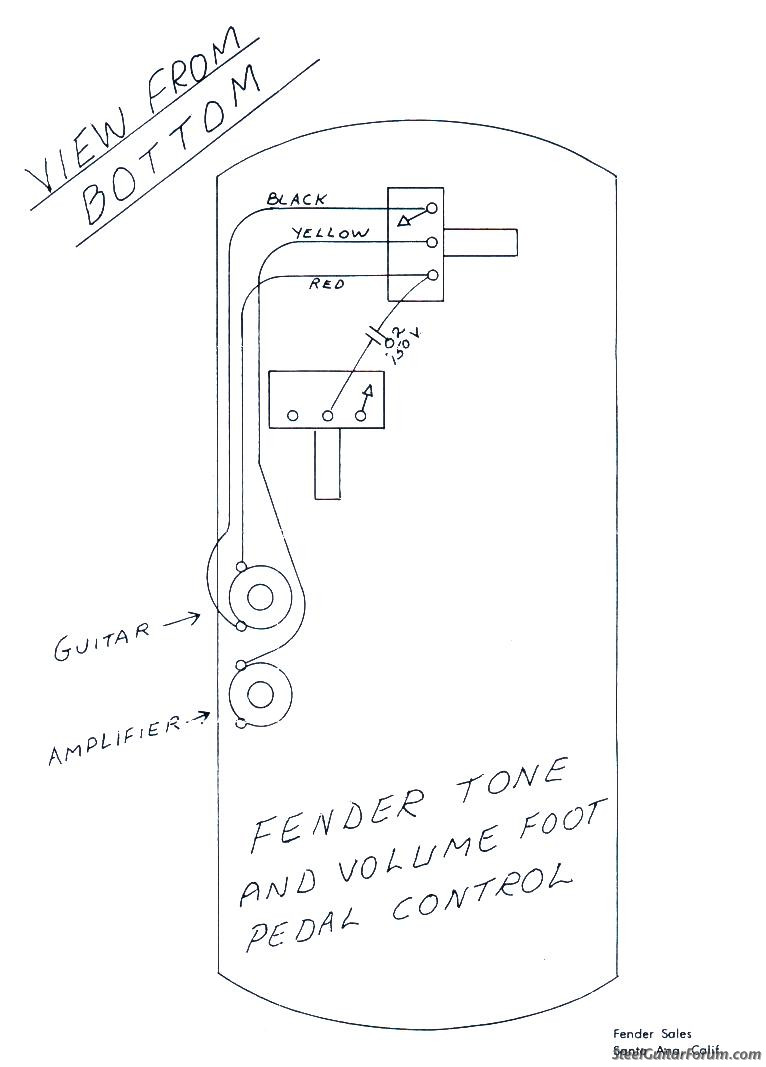

Also, does anyone have the schematic for how these best go together?

The pedal I have has the block style script logo like the amps from the mid 50s'. Is this pedal that old? Kind of smells like it.

Any help is appreciated!

I just picked up an old Fender Volume/tone pedal and someone removed the tone pot from the circuit (left the pot). The pulley that goes over the tone pot post is missing as well as the string and spring. Everything else seems to be there.

Is the pulley that goes over the volume and tone pot posts the same size? I may need to fabricate one but don't know what size it needs to be.

Also, does anyone have the schematic for how these best go together?

The pedal I have has the block style script logo like the amps from the mid 50s'. Is this pedal that old? Kind of smells like it.

Any help is appreciated!

Microphones, Recording, and lots of pedal steel guitars!

-

Ken Fox

- Posts: 9724

- Joined: 20 Apr 2001 12:01 am

- Location: Nashville GA USA

1. The cord should be a 'healthy' sized 'cotton'-type cord, as opposed to the synthetic narrow 'fishing'-type used in many of todays pedals.

2. Where the volume-cord ends pass thru a holes, they are 'knotted' to keep them secure from slipping thru.

3. The ends of the tone-cord are tied to the end of its tension spring.

4.The tone-cord passes one and one-half turns around the 'barrel' on the tone-pot shaft.

5.The volume-cord passes one and one-quarter turns around the 'barrel' on the volume-pot shaft.

6.The amount of pull required of the tension springs are minimal, barely separating their coils (provided the pulleys and pots turn freely on their own).

7.When properly strung, the volume-cord will pass through the 'loop' created by tone-cord.

8.There should be a single steel ball in the curved groove in the 'toe-area' between the 'foot-treadle' and the upper portion of the pedals main structure. This ball acts as a bearing for lateral movement of the forward (toe) part of the 'foot-treadle'.

2. Where the volume-cord ends pass thru a holes, they are 'knotted' to keep them secure from slipping thru.

3. The ends of the tone-cord are tied to the end of its tension spring.

4.The tone-cord passes one and one-half turns around the 'barrel' on the tone-pot shaft.

5.The volume-cord passes one and one-quarter turns around the 'barrel' on the volume-pot shaft.

6.The amount of pull required of the tension springs are minimal, barely separating their coils (provided the pulleys and pots turn freely on their own).

7.When properly strung, the volume-cord will pass through the 'loop' created by tone-cord.

8.There should be a single steel ball in the curved groove in the 'toe-area' between the 'foot-treadle' and the upper portion of the pedals main structure. This ball acts as a bearing for lateral movement of the forward (toe) part of the 'foot-treadle'.

-

Patrick Timmins

- Posts: 197

- Joined: 19 Jul 2019 1:32 pm

- Location: Seattle

-

Patrick Timmins

- Posts: 197

- Joined: 19 Jul 2019 1:32 pm

- Location: Seattle