| Author |

Topic: Rick B6 with Inconsistent String Spacings (Repairable?) |

Ted Duross

From:

Ottawa, Ontario, Canada

|

Posted 12 Jan 2017 8:49 am

Posted 12 Jan 2017 8:49 am |

|

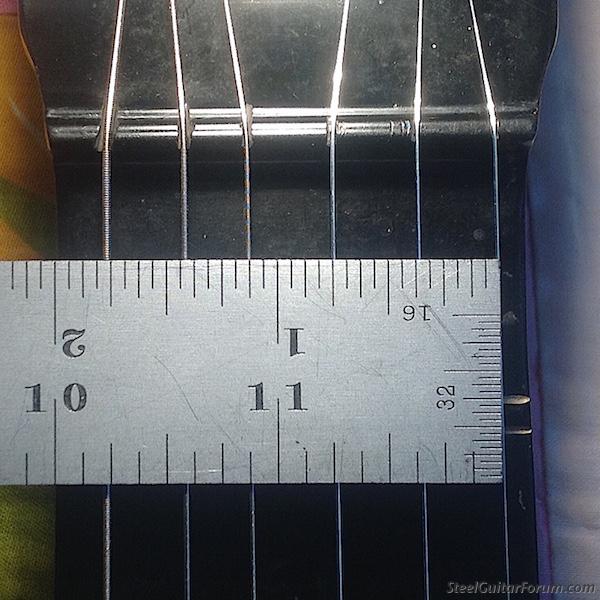

Hi! I recently purchased a late 40s Rickenbacher B6 online. I’ve had it for a month now. It’s a wonderful guitar. Great tone and sustain. However I quickly realized that the string spacings at the nut were inconsistent.

For strings 1 to 4 the spacings are approximately 3/8ths. But the space between the 4th and 5th string is slightly less than 5/16ths. While space between the 5th and 6th is slightly more than 5/16ths.

I’m wondering whether it would be possible to reposition the slots for the 5th and 6th string.

I was kind of encouraged by a thread from May 2016 that talks about refilling and re-cutting a slot on a 1948 Rick. It was recommended that Devcon Steel Epoxy be used to fill the slot which could then be refiled.

http://bb.steelguitarforum.com/viewtopic.php?p=2515019&sid=75b3084b5161644e7b85f2e0b5fc31ab

I realize that mine is a different venture but wondered if people might have thoughts or experiences they might share.

Many thanks! |

|

|

|

Jack Hanson

From:

San Luis Valley, USA

|

Posted 12 Jan 2017 11:31 am

Posted 12 Jan 2017 11:31 am |

|

That nut definitely needs some help. If you plan on doing the job yourself, I would recommend closely following Mr. Aiello's advice. If you have never cut a new nut before, study up on it. There are some videos on the Stewart-MacDonald website and elsewhere.

Properly gauged nut files are highly recommended. If you're going to submit a Stew-Mac order, I would definitely recommend getting one of these. Although expensive, I consider mine indispensable:

http://www.stewmac.com/Luthier_Tools/Tools_by_Job/Tools_for_Measuring/String_Spacing_Rule.html

Good luck, and enjoy your B6. Mine is the best sounding guitar in my collection. |

|

|

|

Ted Duross

From:

Ottawa, Ontario, Canada

|

Posted 12 Jan 2017 1:15 pm

Posted 12 Jan 2017 1:15 pm |

|

Thanks, Jack. I would like to attempt this on my own if it is feasible. I would certainly pick up a few nut slotting files from Stewmac if I go ahead.

My concern is particularly with cutting a new slot for the 6th string. Am I right in thinking that this ought to be positioned at the 1 and 7/8ths mark in my picture? So if I’ve filled the previous slot with Devcon Steel Epoxy and let it cure 7 days will the bakelite have the structural integrity to allow me to file the new slot?

I checked out the StewMac video for the string spacing rule. Very interesting…. Budget allowing : ) |

|

|

|

Jack Hanson

From:

San Luis Valley, USA

|

Posted 12 Jan 2017 2:41 pm

Posted 12 Jan 2017 2:41 pm |

|

| Ted Duross wrote: |

| My concern is particularly with cutting a new slot for the 6th string. Am I right in thinking that this ought to be positioned at the 1 and 7/8ths mark in my picture? |

It appears that the slots for the fourth, fifth and sixth strings are all somewhat askew. And what's with those shims under the strings? I suppose you could merely fill the offending slots and leave the rest alone, but I would recommend filling 'em all and starting from scratch.

If you choose to go that route, any specific measurements would be premature until the existing slots were filled, fully cured, and sanded smooth. |

|

|

|

Ted Duross

From:

Ottawa, Ontario, Canada

|

Posted 12 Jan 2017 4:07 pm

Posted 12 Jan 2017 4:07 pm |

|

| Quote: |

| And what's with those shims under the strings? |

Although it looks like it, there are actually no shims. The lighting in the photo is probably highlighting the surface of the slot channels. Here’s another photo that may help to show it a bit better. It's just that the cuts are a bit ragged.

| Quote: |

| but I would recommend filling 'em all and starting from scratch. |

To be honest my confidence in skills... and level of bravery... would only extend to adjusting the 5th and 6th. I would hate to do any irreversible damage... But I think this comes mainly from being unsure of how bakelite is to work with. |

|

|

|

Ted Duross

From:

Ottawa, Ontario, Canada

|

Posted 13 Jan 2017 12:29 pm

Posted 13 Jan 2017 12:29 pm |

|

The more I look at photos of B6 headstocks the more I come to realize that Jack’s recommendation to ‘fill ‘em all and start from scratch’ might be the best way to go. As Jack mentions there are more irregularities than just the positioning of the 5th and 6th strings. For example the distance between 1st and 2nd is also irregular.

Also I'm wondering if the overall distance between the 1st and 6th string at the nut is less than the norm. Mine measures 1 and ¾ inch + 1/32nd from the outside of the 1st to the outside of the 6th.

I wonder if someone could help me out by measuring the distance at the nut from outside the 1st to outside the 6th string on their B6. This would be very helpful as it would give me a ballpark of how much overall adjustment I would need to make.

Much appreciated. Thanks.

Last edited by Ted Duross on 14 Jan 2017 8:06 am; edited 1 time in total |

|

|

|

Rick Barnhart

From:

Arizona, USA

|

Posted 13 Jan 2017 2:53 pm

Posted 13 Jan 2017 2:53 pm |

|

Ted give a shout to Georgeboards. He has some templates that may work for your application. He's quite a good resource for things like spacing, etc.

_________________

Clinesmith consoles D-8/6 5 pedal, D-8 3 pedal & A25 Frypan, Pettingill Teardrop, & P8 Deluxe. |

|

|

|

Ted Duross

From:

Ottawa, Ontario, Canada

|

Posted 14 Jan 2017 4:06 am

Posted 14 Jan 2017 4:06 am |

|

Thanks, Rick.

That's a great site. Some beautiful guitars. I love that he has lap steel kits where it looks like he's done ALL the preliminary work... painted, nut and bridge, pots, a very classy looking fretboard, shielded chambers for the electronics... all you do is add your pickup... Hard to beat for $359!

I knew that a while back he had replacement plates for the Rick B6s. I'll email him to see if he has any info that could be helpful for this project. |

|

|

|

Robert Allen

From:

Tennessee, USA

|

Posted 14 Jan 2017 7:06 am

Posted 14 Jan 2017 7:06 am |

|

I have two of the Stew Mac string spacing rules as well as $300 worth of their nut files. I highly recommend Stew Mac for someone in the business. However, for someone repairing only one nut, there's no need to invest this much money. The Stew Mac string spacing rule is great for guitars and banjos but there is no need to have proportional string spacing on a steel guitar. In this case, I'd recommend buying either the Georgeboards gauge or a plastic ruler at the dime store for 99 cents. I have several rulers and have used them for slotting nuts many times. A set of jeweler's files is about $4 at the hardware store. Even with Stew Mac gauges it takes some practice to accurately cut slots, so before filing the nut on the lap steel, practice on some scraps. |

|

|

|

Ted Duross

From:

Ottawa, Ontario, Canada

|

Posted 14 Jan 2017 10:45 am

Posted 14 Jan 2017 10:45 am |

|

Thanks Robert and George.

The consensus seems to be that a String Spacing Rule, while certainly an invaluable tool for a variety of instruments, is not a necessity when positioning strings on a lap steel. Therefore the distance between 1st and 6th string (given a 3/8ths spacing) can be 1 7/8th inch. This is good for me as it allows me to revert to my original plan of reslotting only the 5th and 6th string. This ought to centre the strings quite well.

The distance between 1st and 2nd is a little less than optimal but I can live with that. I’m more concerned with those other two strings.

Devcon Epoxy products are not readily available in Canada but I’ve found an online source.

The string gauges for these strings are .030 and .036. StewMac has gauged nut slotting files for .032 and .035. I’m hoping these will do the trick.

I like Robert’s suggestion of picking up an inexpensive set of jeweler’s files to do some practice in advance.

Thanks to all for your input.

I’ll get back with pictures when I’m up and running with this : ) |

|

|

|

Jack Hanson

From:

San Luis Valley, USA

|

Posted 14 Jan 2017 3:30 pm

Posted 14 Jan 2017 3:30 pm |

|

Totally agree that for a one-time repair of only a couple string slots, the expensive Stew-Mac String Spacing Rule would be overkill.

After studying Ted's photos a little more closely, it now seems like what first appeared to be shims in the 4-6 positions, are actually excessively deep string slots. If that is indeed the case, I would be inclined to fill all six slots and begin anew.

My B6 is also an early postwar model with the metal "T" logo on the headstock. It also has somewhat irregular nut slots, presumably from the factory. The spacing between strings three and four is slightly although visibly wider than the spacing between the other strings. Perhaps both of our instruments came off the line early on a Monday morning (or else late on a Friday afternoon).

The approximate measurement from the centers of strings one and six at the nut on my guitar is also within a hair of 1-7/8 inches. |

|

|

|

Ted Duross

From:

Ottawa, Ontario, Canada

|

Posted 15 Jan 2017 7:30 am

Posted 15 Jan 2017 7:30 am |

|

Thanks for doing that measure, Jack.

| Quote: |

| Perhaps both of our instruments came off the line early on a Monday morning (or else late on a Friday afternoon). |

My thought exactly  |

|

|

|

Stuart McKenzie

From:

Hawaii, USA

|

Posted 16 Jan 2017 10:43 am

Posted 16 Jan 2017 10:43 am |

|

Ted, I would encourage you to give it a try. Follow rick's instructions. Hey, if it doesn't work the first time, just do it again... and wait the recommended 1 week for a cure time.

Brudda Stu |

|

|

|

Ted Duross

From:

Ottawa, Ontario, Canada

|

Posted 17 Jan 2017 4:29 am

Posted 17 Jan 2017 4:29 am |

|

Hi Stuart,

Thanks for the encouraging words… I’ve gotten some good advice and a lot of food for thought from this and another thread.

Here’s what I’ve concluded. Filling the old slots with epoxy and repositioning them would work fine.

Here’s the sticking point for me. One of the other threads included advice ‘not to breath in’ any of the bakelite filings. That got me looking into the use of asbestos as a filler in bakelite products. I discovered that a wide range of fillers had been used over the years including wood pulp, mica, ground walnut shells… but also asbestos. I was not able to find anything authoritative that said Rickenbacker (or its supplier) was not using asbestos during the late 40’s... If anything its use in the plastics industry seemed to be ramping up during the 50s and 60s.

My project would have involved recutting at least 2 and possibly 6 new slots in the bakelite nut. I couldn’t be certain, but I felt there might be some potential health risks… If I were just refilling the holes and filing down the epoxy I’d be fine with it.

So I’m going to leave the nut as it is and learn to play around the imperfections. This is still an amazing guitar!

I will however replace the tuners... But I’ll have a shop recut the metal holes so they match up with the ones already there.

Thanks again for your encouragement. I hope you’re enjoying your B6 as much as I’m enjoying mine! |

|

|

|

Bill Creller

From:

Saginaw, Michigan, USA (deceased)

|

Posted 18 Jan 2017 4:45 pm

Posted 18 Jan 2017 4:45 pm |

|

One other thing you may want to consider is the height level of the strings, like try to get them level with each other across the top. If you get your bar down on the lower frets occasionally, level strings can prevent some buzz !

Rickenbacker didn't seem to be fussy about string spacing on the nuts. I made a new nut ( or was it both ?) don't remember, on a Rick D8, aluminum nuts on that one. It was not feasible to start over, because of the height of the nuts, which would end up too low if I shaved them down... |

|

|

|

Ted Duross

From:

Ottawa, Ontario, Canada

|

Posted 19 Jan 2017 4:21 am

Posted 19 Jan 2017 4:21 am |

|

Thanks, Bill.

I'm lucky with the string levels. Even though it appears to be a bit of a hack job in the cutting, actually the levels are bang on.

That's interesting to hear you mention that Rickenbacker didn't seem too fussy about string spacing... You're the third person in this thread to mention having this type of problem.

Actually I'm finding that it doesn't influence my playing too much... I'm still as bad as ever  |

|

|

|