| Author |

Topic: My Homemade Pedal Steel Guitar |

W. Johnson

From:

Oregon, USA

|

Posted 27 Mar 2013 8:35 pm

Posted 27 Mar 2013 8:35 pm |

|

Hello all, this is my first post here on this forum. I'd like to share with you about my homemade guitar I've built for myself.

I used to play guitar, for about 22 years, until I got arthritis in my fingers, and about 18 years ago I had to stop. About 3 or 4 years ago, the idea occurred to me I might be able to play the pedal steel guitar. Unfortunately, the cost is way beyond my means. So, being a machinist, I decided to build one. I purchased Gluck's plans, sort of helpful, a little. I spent untold hours looking at pictures, trying to see into the mechanism of the thing, how it works. Up to this day I have only seen pictures of pedal steel guitars, I've never touched one or been around one. I looked at all the possibilities, and finally decided on my design. Basically, I wanted my guitar to be able to play full chords, I'm not so interested in playing country music. So, I wanted to be able to play major, minor, 7th, minor 7th, and major 7th chords. My final design does not play M7 chords, but does everything else I wanted it to. It has a mellow sound, not bright or 'hot', due to the kind of pickup I used, and it's placement farther away from the bridge.

Anyway, here are some pictures. I am about ready to tear it all apart again, and finish the wood, buff the aluminum. So it looks rough and unfinished. The fingerboard is just sitting on the top, as I plan to make a wood fretted fingerboard, or a brass fingerboard with frets (I think brass against the silver aluminum will look nice.)

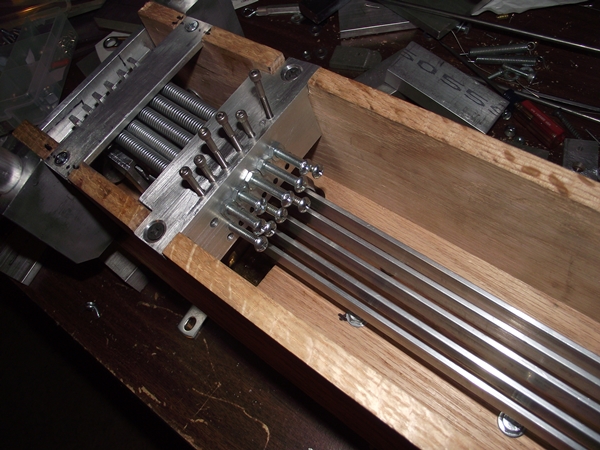

The unique design of rockers for the pedals, and one tuning rod per finger, that both will push or pull (lower or raise)

In the following pic, you can see the small bearings I used, at each joint. In the changer fingers, I also used the same bearings.

I can raise or lower the notes. I have tuned the guitar to open E, from high to low: E - G# - E - B - G# - E. Pedal 1 lowers G# strings to G for a minor chord. Pedal 2 raises G string to A. Pedal 3 raises B to C#. Pressing pedals 2 and 3 gives me a IV chord, so I have the 'I - IV' chord progression. Pedal 2 alone gives me a 4th note in the chord. Pedal 4 lowers middle E to D for a 7th chord.

I've got hours of playing on it since last week when I finished it. It seems to hold it's tuning well. Getting the string stops right is a trick, and tuning two G# strings together to lower or raise exactly perfect is a trick to, but is doing well. My problem is getting the bar on the strings exactly right for the chords.

I was never a professional musician. Basically, I used to play guitar in small Christian group meetings. That's why I wanted to be able to strum or pick. I can't get those finger pick things to stay on my fingers, so, I just use a regular guitar pick, or strum with my fingers.

I have a Youtube channel, elektrolumens (I manufacture and sell flashlights for a living, hence the name elektrolumens), and I'll post a video of me playing my guitar some time soon. I just play simple songs, not professional at all by any means, and the songs I'll record will be Christian songs. Maybe I'll do some standards everyone knows, like 'Amazing Grace' and 'Just As I Am', something like that.

I wonder how many former guitar players there are, who, like me, had to stop because of arthritis, carpel tunnel, or something like that?

W. Johnson |

|

|

|

Mitch Ellis

From:

Collins, Mississippi USA

|

Posted 27 Mar 2013 10:06 pm

Posted 27 Mar 2013 10:06 pm |

|

W. Johnson,

First of all, welcome to the forum!  I think that you did a GREAT job building that guitar! Especially considering that you've never been around steel guitars before. It's very impressive. I've been playing steel for about 15 years and I also do steel guitar repair work. I'm a mechanic (to a degree)and I love to tinker with things. On one steel that I have, I Redesigned the three foot petals, relocated three of the knee levers, and added a flag to one knee lever. This alone took many hours so I can only imagine at the time that you have invested in making your guitar. I am not a machinist and only have simple hand tools to work with, but I've always wanted to build a steel guitar. Since you're a machinist, and I like to tinker,if we were neighbors, I'd worry you to death! I think that you did a GREAT job building that guitar! Especially considering that you've never been around steel guitars before. It's very impressive. I've been playing steel for about 15 years and I also do steel guitar repair work. I'm a mechanic (to a degree)and I love to tinker with things. On one steel that I have, I Redesigned the three foot petals, relocated three of the knee levers, and added a flag to one knee lever. This alone took many hours so I can only imagine at the time that you have invested in making your guitar. I am not a machinist and only have simple hand tools to work with, but I've always wanted to build a steel guitar. Since you're a machinist, and I like to tinker,if we were neighbors, I'd worry you to death!  A person with your equiptment and skills could be very valuable to me! A person with your equiptment and skills could be very valuable to me!  Again, I think the guitar looks great and I applaud you for your effort. Again, I think the guitar looks great and I applaud you for your effort.

Mitch |

|

|

|

W. Johnson

From:

Oregon, USA

|

Posted 27 Mar 2013 10:37 pm

Posted 27 Mar 2013 10:37 pm |

|

| Mitch Ellis wrote: |

W. Johnson,

First of all, welcome to the forum!  I think that you did a GREAT job building that guitar! Especially considering that you've never been around steel guitars before. It's very impressive. I've been playing steel for about 15 years and I also do steel guitar repair work. I'm a mechanic (to a degree)and I love to tinker with things. On one steel that I have, I Redesigned the three foot petals, relocated three of the knee levers, and added a flag to one knee lever. This alone took many hours so I can only imagine at the time that you have invested in making your guitar. I am not a machinist and only have simple hand tools to work with, but I've always wanted to build a steel guitar. Since you're a machinist, and I like to tinker,if we were neighbors, I'd worry you to death! I think that you did a GREAT job building that guitar! Especially considering that you've never been around steel guitars before. It's very impressive. I've been playing steel for about 15 years and I also do steel guitar repair work. I'm a mechanic (to a degree)and I love to tinker with things. On one steel that I have, I Redesigned the three foot petals, relocated three of the knee levers, and added a flag to one knee lever. This alone took many hours so I can only imagine at the time that you have invested in making your guitar. I am not a machinist and only have simple hand tools to work with, but I've always wanted to build a steel guitar. Since you're a machinist, and I like to tinker,if we were neighbors, I'd worry you to death!  A person with your equiptment and skills could be very valuable to me! A person with your equiptment and skills could be very valuable to me!  Again, I think the guitar looks great and I applaud you for your effort. Again, I think the guitar looks great and I applaud you for your effort.

Mitch |

Thanks Mitch! I started on this project about 3 years ago. It sat in storage for about 7 months, until about 1 month ago I decided I had to finish it. I did spend many hours on this, and I found 1000 ways that didn't work (partial quote from Thomas Edison.)

My equipment is all manual lathes and a mill, no CNC.

Why would you put a flag on a knee lever? Is it patriotic?

W. Johnson |

|

|

|

Mitch Ellis

From:

Collins, Mississippi USA

|

Posted 27 Mar 2013 11:52 pm

Posted 27 Mar 2013 11:52 pm |

|

| W. Johnson wrote: |

Why would you put a flag on a knee lever? Is it patriotic?

W. Johnson |

W. Johnson,

A "flag", or so it's called, is a flat piece of metal, usually aluminum, that is screwed onto the inside surface of a knee lever. Some knee levers pull four or maybe five strings, which makes them a little stiff. The "flag" gives your leg a wider surface to push against, thus making it more comfortable. Another reason for the flag is to help you engage a knee lever that is almost out of reach. The reason it is called a "flag" is because the knee lever with the flat piece of metal attached to it resembles a flag on a flag pole and a flag on a mailbox. I'd be happy to show you, but I don't know how to post pictures. ha!ha! Keep looking a pictures of steel guitars and you'll soon come across one. Have a great day!

Mitch |

|

|

|

Adrian Wang

From:

Singapore

|

Posted 28 Mar 2013 3:01 am

Posted 28 Mar 2013 3:01 am |

|

Hi Wayne,

Great job making steel and led flashlight.

I like them both. |

|

|

|

W. Johnson

From:

Oregon, USA

|

Posted 28 Mar 2013 9:45 am

Posted 28 Mar 2013 9:45 am |

|

| Mitch Ellis wrote: |

| W. Johnson wrote: |

Why would you put a flag on a knee lever? Is it patriotic?

W. Johnson |

W. Johnson,

A "flag", or so it's called, is a flat piece of metal, usually aluminum, that is screwed onto the inside surface of a knee lever. Some knee levers pull four or maybe five strings, which makes them a little stiff. The "flag" gives your leg a wider surface to push against, thus making it more comfortable. Another reason for the flag is to help you engage a knee lever that is almost out of reach. The reason it is called a "flag" is because the knee lever with the flat piece of metal attached to it resembles a flag on a flag pole and a flag on a mailbox. I'd be happy to show you, but I don't know how to post pictures. ha!ha! Keep looking a pictures of steel guitars and you'll soon come across one. Have a great day!

Mitch |

Ah, knee lever flag, very good idea. My next guitar will be a big lap steel (aluminum deck 3/4" x 6" x 30"), more like a console steel guitar, and rather than palm pedals I think knee levers make more sense. I like the pedal steel, but, it's not very portable. I don't like the limitations of a lap steel guitar, that is, I cannot do what I want in terms of chord changes. I think a console steel with knee levers would be a kind of in-between thing. I'm thinking four levers (with flags) having the same functionality as my pedal steel (I-IV, minor, 7th) would work. Since there will be no pedals or legs to fiddle with, it would be more portable, yet I could accomplish the same thing. Well, so far I've never tried knee levers, but in concept they sound like a good idea.

W. Johnson |

|

|

|

Bent Romnes

From:

London,Ontario, Canada

|

Posted 28 Mar 2013 10:25 am

Posted 28 Mar 2013 10:25 am |

|

W. Johnson,

Welcome to the forum. You have built yourself a solid hunk of pedal steel guitar! I would love to learn more in detail about your unique changer system, very intriguing indeed.

Overall a nice looking guitar.

I hope this won't be the last one you make.

_________________

BenRom Pedal Steel Guitars

https://www.facebook.com/groups/212050572323614/ |

|

|

|

W. Johnson

From:

Oregon, USA

|

Posted 28 Mar 2013 11:01 am

Posted 28 Mar 2013 11:01 am |

|

| Bent Romnes wrote: |

W. Johnson,

Welcome to the forum. You have built yourself a solid hunk of pedal steel guitar! I would love to learn more in detail about your unique changer system, very intriguing indeed.

Overall a nice looking guitar.

I hope this won't be the last one you make. |

The changer system has two piece fingers. A rod with a bearing is inserted into one of the two fingers, and the rod is pulled to raise the note. The rod is pushed, going against the spring tension (adjustable tension), to raise the note. The rod is connected to a rocker, which has two pedals connected with rods. Bearings are at each connection, except the in the pedals (might upgrade to put a bearing into the pedals later.) My thought is, no metal to metal to reduce wear and tear, so no looseness in the future, and also makes it easier to work not having excess friction. The rods are 1/8" thick by 3/4". My concern was that one pedal would be raised when the other is pushed down, and yes, this happens, but the amount of movement is small and, does not pose a problem. If you were watching me press a pedal down, you might not notice the reciprocal pedal rising. It works really well.

The stops have 32 TPI threading, so very fine to get an exact tuning for the fingers, and, once set, seem to stay put. I lock the raise tuning bolts with a second bolt so it does not turn. The lowers stops have nuts to lock the bolts. Once I get them set, they seem to stay put and not change. The springs have adjustable tension to match each string individually.

It's very difficult to get the two G# strings to raise exactly to the correct pitch A, and I had to work with this a lot. The lower to G is also difficult. But once set, seems to stay put.

The rod the fingers are on is just steel, later I will upgrade to stainless steel.

Everything is rough and not finished for appearance, as I have continuously made changes, assembling and disassembling many times. I never know if something is going to work or not, many times I designed something and then tossed the idea (and part). I don't really want to tear it apart again, but, eventually I need to.

Here are a few photos:

I decided not to go with the standard 3 part changer finger. I did even make a few parts for it, but decided a 2 part changer finger was adequate, and I could raise and lower the notes as I wished. I spent a huge amount of time making each finger.

As for making more pedal steels, I only need one, and it took me about 3 years to make. I might make some lap steels with palm pedals or knee levers, with chord changing capacity like this one. My thought is that mine is so simple compared to the S10's and D10's. It works for me. It's simple and easy to play. I can strum it like a regular guitar if I want, use my bare fingers to strum it, or use a pick to strum or pick, and always hit the right strings, as any string is in the correct chord.  The hardest thing is to get the placement of the bar correct so the chord is in tune, and I'm a beginner at this, so sometimes it right on, other times it's a bit off (like sometimes I slant the bar, or press too hard or not hard enough, etc.) The hardest thing is to get the placement of the bar correct so the chord is in tune, and I'm a beginner at this, so sometimes it right on, other times it's a bit off (like sometimes I slant the bar, or press too hard or not hard enough, etc.)

I was going to call my guitar 'Elektro Steel', but, there is a company with that name. Elektro is what I go by sometimes, and, my company is Elektro Lumens.

W. Johnson |

|

|

|

Peter den Hartogh

From:

Cape Town, South Africa

|

Posted 28 Mar 2013 2:32 pm

Posted 28 Mar 2013 2:32 pm |

|

To synchronize the two G# strings (string 2 and 5) you may need to experiment with the string gauges.

I had this problem on a pedal steel where I could not adjust bell crank connections for timings.

It was solved when I changed the low G# (string 5) to a wound .024 gauge string. My high G# was a .012 I think.

This was on a 24" scale guitar. |

|

|

|

W. Johnson

From:

Oregon, USA

|

Posted 28 Mar 2013 3:09 pm

Posted 28 Mar 2013 3:09 pm |

|

| Peter den Hartogh wrote: |

To synchronize the two G# strings (string 2 and 5) you may need to experiment with the string gauges.

I had this problem on a pedal steel where I could not adjust bell crank connections for timings.

It was solved when I changed the low G# (string 5) to a wound .024 gauge string. My high G# was a .012 I think.

This was on a 24" scale guitar. |

Okay, I can try different gauges of strings. However, it is working, it just takes patience to get it perfect. I'm using ghs pure nickel rollerwound: 016, 018, N28, N36, N46, N56. My guitar is 24" scale.

What do you mean by "adjust bell crank connections for timings?"

W. Johnson |

|

|

|

Peter den Hartogh

From:

Cape Town, South Africa

|

|

|

|

W. Johnson

From:

Oregon, USA

|

Posted 29 Mar 2013 9:53 am

Posted 29 Mar 2013 9:53 am |

|

Thanks. I just didn't understand the terminology. I suppose I could have just looked it up.

Wayne |

|

|

|

W. Johnson

From:

Oregon, USA

|

Posted 13 Apr 2013 3:59 pm My Homemade Pedal Steel Guitar

Posted 13 Apr 2013 3:59 pm My Homemade Pedal Steel Guitar |

|

I made a little video of my homemade pedal steel guitar, and uploaded it to my YouTube channel. Here is a link, if anyone is interested in hearing it. I hope it's not too boring:

http://www.youtube.com/watch?v=LnlEI1z-taU&feature=youtu.be

Here's a picture of me with my guitar:

W. Johnson |

|

|

|

Alan Brookes

From:

Brummy living in Southern California

|

Posted 13 Apr 2013 4:23 pm

Posted 13 Apr 2013 4:23 pm |

|

It's a brave man who builds his own pedal steel. You get a lot of credit for that.  I would have liked to hear it, but the YouTube video's volume is so low it makes virtually no sound on my monitor. I would have liked to hear it, but the YouTube video's volume is so low it makes virtually no sound on my monitor.  |

|

|

|

W. Johnson

From:

Oregon, USA

|

Posted 13 Apr 2013 4:30 pm

Posted 13 Apr 2013 4:30 pm |

|

| Alan Brookes wrote: |

It's a brave man who builds his own pedal steel. You get a lot of credit for that.  I would have liked to hear it, but the YouTube video's volume is so low it makes virtually no sound on my monitor. I would have liked to hear it, but the YouTube video's volume is so low it makes virtually no sound on my monitor.  |

Oh, sorry about the volume. I'm not sure why it's so low. I guess I'll have to give another whirl at recording it.  Actually, I have to plug in my head phones to hear it, I thought it was just my computer. I'll do another video and see if I can improve on the sound. I guess I'll delete this video. My apologies for the poor recording. Actually, I have to plug in my head phones to hear it, I thought it was just my computer. I'll do another video and see if I can improve on the sound. I guess I'll delete this video. My apologies for the poor recording.

W. Johnson |

|

|

|

W. Johnson

From:

Oregon, USA

|

|

|

|

Georg Sørtun

From:

Mandal, Agder, Norway

|

Posted 13 Apr 2013 11:48 pm

Posted 13 Apr 2013 11:48 pm |

|

Coming through fine now.

Seeing what you're playing with, and how, I'd have to say your homebuilt PSG sounds pretty good. |

|

|

|

W. Johnson

From:

Oregon, USA

|

Posted 14 Apr 2013 7:21 am

Posted 14 Apr 2013 7:21 am |

|

| Georg Sørtun wrote: |

Coming through fine now.

Seeing what you're playing with, and how, I'd have to say your homebuilt PSG sounds pretty good. |

Thanks Georg. The pickup and the tuners are actually not very good quality. I purposely set the pickup farther away from the bridge to get a more mellow tone. I don't know very much about electric guitars, but I think that it gets what is called 'muddy', if I turn the volume up too high, or strike the strings harder. I didn't want to invest a lot of money into the components because I didn't even know if it would ever really work.

One thing I wish I had done is to make the box bigger, it was hard to work in the small confines of a 6" wide box. I also felt that the fingers were narrow and the target spot for the adjustable stops was small and difficult to hit.

I'm starting another steel guitar, this time it will be a console steel with four knee levers, and I'm hoping for a brighter tone. Since it is 'steel without pedals', I'll probably start a thread in the 'steel without pedals' section, as I'd like input on design. I will improve on my design and try and improve on sound quality, and use better components. I'm using a 7" x 32" x 3/4" aluminum bar as the deck, similar to this design here but it is 1" wider and 1" longer. I won't say too much about this here in this thread.

This guitar here has really good sustain, but the low strings do kind of thud up on the higher frets (not sure why?), compared to when they are open strings.

This project was fun and interesting, and now I have a playable PSG guitar.

W. Johnson |

|

|

|

Lane Gray

From:

Topeka, KS

|

Posted 14 Apr 2013 7:43 am

Posted 14 Apr 2013 7:43 am |

|

I'm not positive, but I would think that if it has knee levers, it would still be long here rather than the steel without pedals section because the changer mechanism alters the whole ball game.

_________________

2 pedal steels, a lapStrat, and an 8-string Dobro (and 3 ukes)

More amps than guitars, and not many effects |

|

|

|

W. Johnson

From:

Oregon, USA

|

Posted 14 Apr 2013 3:15 pm

Posted 14 Apr 2013 3:15 pm |

|

| Lane Gray wrote: |

| I'm not positive, but I would think that if it has knee levers, it would still be long here rather than the steel without pedals section because the changer mechanism alters the whole ball game. |

Hmmmmmm, hadn't considered that.

W. Johnson |

|

|

|

Thiel Hatt

From:

Utah, USA

|

Posted 14 Apr 2013 3:43 pm

Posted 14 Apr 2013 3:43 pm |

|

Here's another version of a home-made pedal steel guitar. But this one is still in progress. It may appear quite complete but in reality it is about 70% there. Except for the tining keys and the pickup it was all fabricated in my meager work shop. (no milling machine)

|

|

|

|

Bill Rowlett

From:

Russellville, AR, USA

|

Posted 14 Apr 2013 3:55 pm

Posted 14 Apr 2013 3:55 pm |

|

Wayne,

That's a great job you've done. I started on a home made guitar that made yours look like a luxury model. You can make great music with it once you get some practice time in.

To make your strings sustain better up the neck you could get a heavier chrome BJS bullet bar. They make a larger version too that might be easier to hold with your arthritis.

Your second and third pedals give you the standard E9th country split pedal changes, so you have that honky tonk option if you ever want it. You can also combine the third pedal and forth pedal to get the standard knee lever V7 effect.

Bill |

|

|

|

W. Johnson

From:

Oregon, USA

|

Posted 14 Apr 2013 5:16 pm

Posted 14 Apr 2013 5:16 pm |

|

| Thiel Hatt wrote: |

Here's another version of a home-made pedal steel guitar. But this one is still in progress. It may appear quite complete but in reality it is about 70% there. Except for the tining keys and the pickup it was all fabricated in my meager work shop. (no milling machine)

|

Whoah! That's awesome! A milling makes things easier probably, but, there are many ways to do things. I probably could have managed with a drill, hack saw and a file, although it would take a lot longer, and, I probably might have done a few things differently.

W. Johnson |

|

|

|

W. Johnson

From:

Oregon, USA

|

Posted 14 Apr 2013 5:32 pm

Posted 14 Apr 2013 5:32 pm |

|

| Bill Rowlett wrote: |

Wayne,

That's a great job you've done. I started on a home made guitar that made yours look like a luxury model. You can make great music with it once you get some practice time in.

To make your strings sustain better up the neck you could get a heavier chrome BJS bullet bar. They make a larger version too that might be easier to hold with your arthritis.

Your second and third pedals give you the standard E9th country split pedal changes, so you have that honky tonk option if you ever want it. You can also combine the third pedal and forth pedal to get the standard knee lever V7 effect.

Bill |

I'll try a heavier bar. As a machinist, I can't imagine buying one if I can just make it.  I'll just make one. The tone bar I have is super easy for me to grip, but it is very light, although it is chromed brass. I have some of that super silky smooth self lubricating industrial plastic coming, I plan to make a tone bar for myself with it, boring into the plastic to insert a brass bar for weight, I'm looking at 7 ounces weight, but, might just do what's right for me. The tricky part will be to machine the rounded end. I'll just make one. The tone bar I have is super easy for me to grip, but it is very light, although it is chromed brass. I have some of that super silky smooth self lubricating industrial plastic coming, I plan to make a tone bar for myself with it, boring into the plastic to insert a brass bar for weight, I'm looking at 7 ounces weight, but, might just do what's right for me. The tricky part will be to machine the rounded end.

The standard E9 country split changes, yeah, I kinda figured that out. I decided it really made a lot of sense to have the I - IV chord capability, so I do not have to bounce all over the place to get the chords I want. In my original design I was only going to lower the 5th string, in this case G#, to G for a minor chord, and to lower one of the E strings to D for a 7th. Later I decided it would be cool to have a 4th added to a chord and a 6th, and have the I-IV ability.

I don't know how to play country music, or scales, and I have a lot of respect for musicians who are able to do so, I can see it's not easy at all. My style of playing is super simplistic for sure.

V7 ?? Why would you do that?

W. Johnson |

|

|

|

Mac Knowles

From:

Almonte,Ontario, Canada

|

Posted 14 Apr 2013 5:57 pm

Posted 14 Apr 2013 5:57 pm |

|

Thiel.....That's a pretty impressive guitar! Did I count 10 knee levers? Can you really use all of this stuff? I know I couldn't and I've been playing steel for 40 years. 5 knee levers is all I can handle.

Cheers,

Mac |

|

|

|